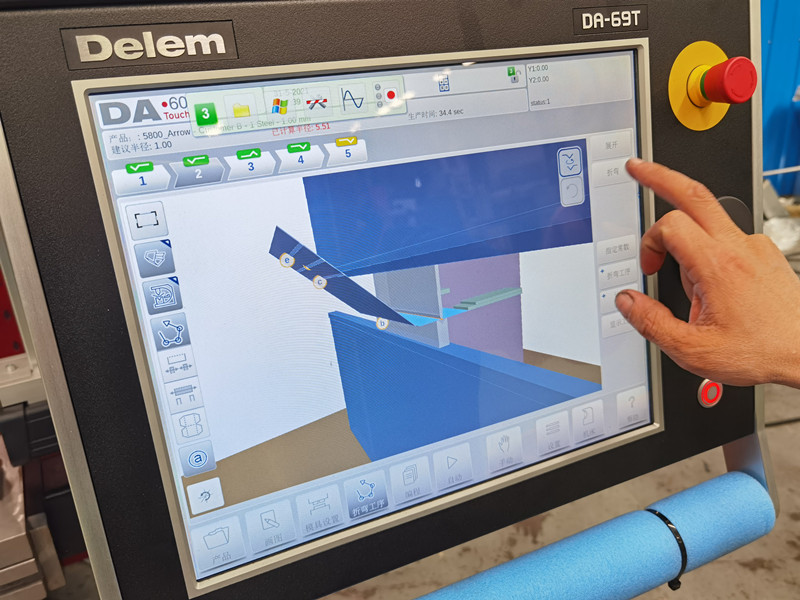

Working characteristics and usage specifications of stainless steel CNC bending machine

Keywords: stainless steel CNC bending machine

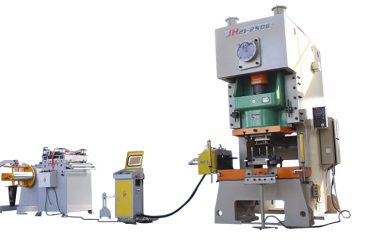

There are many types of CNC bending machines, which can be divided into stainless steel CNC bending machines according to the materials to be made.

As the name suggests, they are mainly bending equipment made of stainless steel plates and are mainly used in the tile press industry. So everyone for this stainless steel

CNC bending machine. Do you know what its working characteristics are? Stainless steel itself has the characteristics of high yield point, high hardness, and remarkable

cold work hardening effect. Under the unit size, the thicker the plate, the greater the bending force required, and the unit size , The greater the tensile strength,

the smaller the elongation, the greater the required bending force, and the greater the bending angle. In addition, do you know the specifications for the use

of this device? If you are not sure, please follow the editor to learn more about it.

Working characteristics of stainless steel CNC bending machine:

Because stainless steel itself has the characteristics of high yield point, high hardness, and significant cold work hardening effect, generally speaking: under the unit size,

the thicker the plate, the greater the bending force required. When selecting the CNC bending machine equipment, As the thickness increases, the margin of bending force

should be greater; in unit size, the greater the tensile strength, the smaller the elongation, the greater the required bending force, and the greater the bending angle.

The principle of CNC bending machine is introduced. In the case of designing the thickness and bending radius of the board, based on experience, the unfolded size

of a bending workpiece is two angles plus and minus the thickness of the right angle. It can fully meet the design accuracy requirements. Calculating the expansion amount

according to the empirical formula can simplify the calculation process and greatly improve the production efficiency.

The greater the bending strength of the material, the greater the elastic recovery, and the smaller the angle of pressure required to obtain a 90-degree bending angle.

Compared with carbon steel of the same thickness, stainless steel has a larger bending angle, which should pay special attention to the occurrence of cracks and affect the

strength of the workpiece.

The springback problem is really troublesome during the processing of the stainless steel CNC bending machine. The solution is to correct the degree of change after the test,

and pay attention to the rebound and radius rebound, and analyze the specific situation. Of course, if the technician’s skills are very good, he will misalign and adjust,

and then adjust the design to make corresponding changes, which depends on the technician’s skills and experience.

Specification for use of stainless steel CNC bending machine:

1. The lubricated parts of the CNC bending machine must be regularly lubricated.

2, before bending, run idling and check that the equipment is normal before operation.

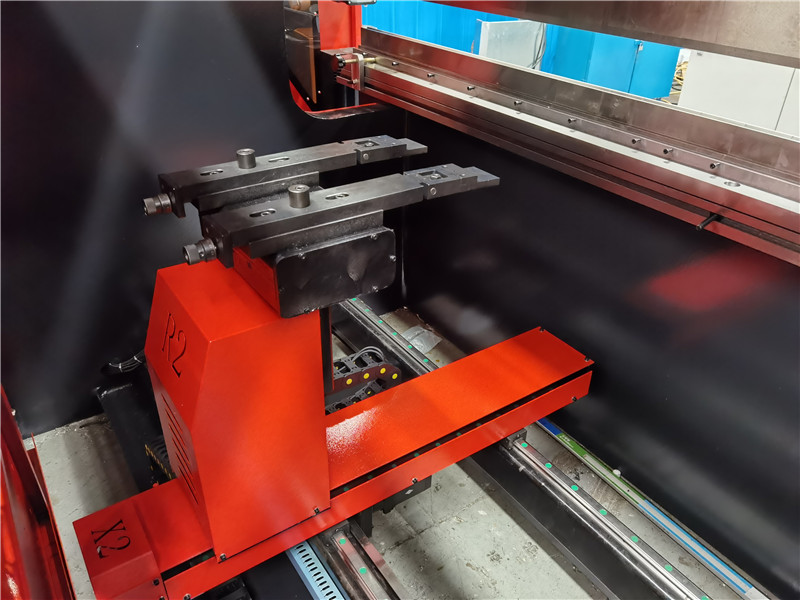

3. It is forbidden to turn on when installing the bending mold.

4. Correctly select the bending mold, the upper and lower molds should be fastened in the correct position, and the upper and lower molds should be installed

to prevent external injuries.

5. Do not stack sundries and tools between the upper and lower molds during bending.

6. When operating by multiple persons, the main operator must be confirmed, and the main operator shall control the use of the foot switch, and other

personnel shall not use it.

7. When bending large parts, prevent the sheet from rising and hurting people.

8. Correctly select the bending pressure, and the pressure should be less than 1/2 of the maximum pressure value during eccentric load.

9. The length of the bending part shall not be less than 1/3 of the length of the worktable.

10. If the CNC bending machine is abnormal, immediately cut off the power supply, stop the operation, and notify the relevant personnel to eliminate the fault in time.

11. After completion, cut off the power supply and clean up the work site.

Have you understood the working characteristics and usage specifications of the stainless steel CNC bending machine after reading the above content?

Relevant operators especially need to read and learn the usage specifications, so that they can know how to use them correctly when they are officially used.