Why fiber laser metal cleaning opportunities are becoming more and more popular

Fiber laser metal cleaning machine

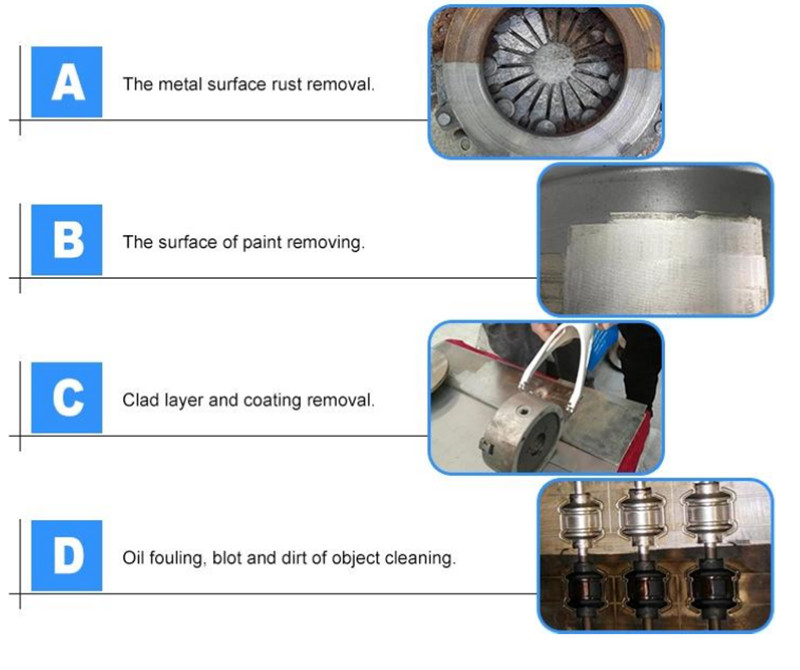

Laser cleaners can not only clean organic pollutants, but also inorganic materials, including metal corrosion, metal particles and dust.

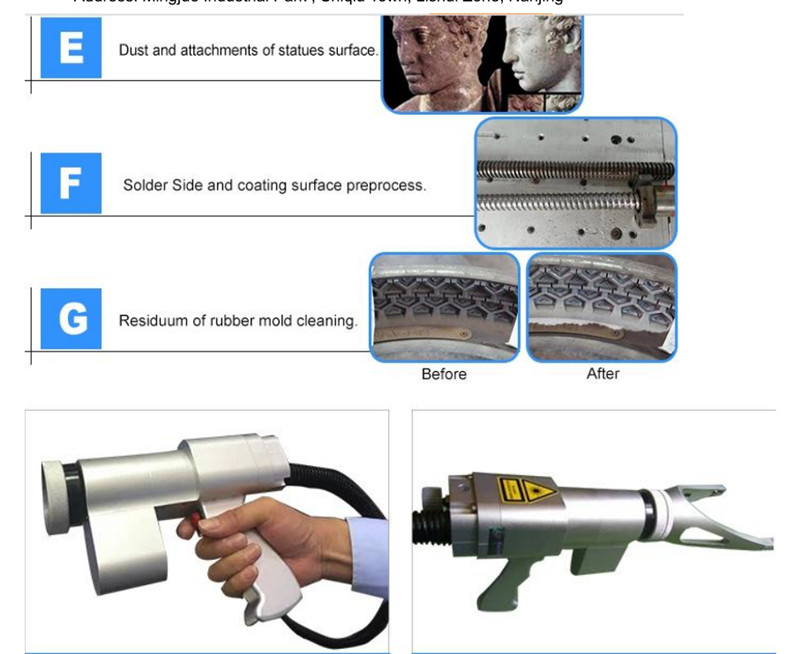

First, mold cleaning:

Use laser cleaning method, flexible to use. Because the laser cleaning method can connect the optical fiber to the dead corner of the mold for cleaning, it is easy to use.

Since rubber will not vaporize, it will not produce toxic gases, which will affect the safety of the working environment. The technology of laser cleaning tire molds has been widely used in the European and American tire industries. Although the initial investment cost is high, it has gained benefits in terms of saving standby time, avoiding mold damage and working safety.

Secondly. Weapons and equipment cleaning:

Laser cleaning technology is widely used in weapon maintenance. The laser cleaning system can quickly remove rust and contaminants and clean automatically. Laser cleaning not only has a higher degree of cleanliness than chemical cleaning processes, but also has minimal damage to the surface of the object.

Third, the old aircraft paint cleaning:

European laser cleaning systems have long existed in the aviation industry. After a period of time, the surface of the aircraft needs to be repainted. The traditional mechanical painting method can easily damage the metal surface of the aircraft and bring hidden dangers to safe flight.

fourth. Clean the exterior wall of the building:

It can effectively clean all kinds of contaminants on all kinds of stone, metal and glass, and it is many times more efficient than conventional cleaning.

fifth. Cleaning in the electronics industry

The electronics industry uses lasers to remove oxides: the electronics industry requires high-precision decontamination, which is particularly suitable for laser deoxidation. Laser cleaning can meet the requirements of use, and the efficiency is very high.

sixth. Precise cleaning in the precision machinery industry:

The precision machinery industry usually requires parts to be lubricated. Usually chemical methods, and chemical cleaning usually still has residues. The laser can completely remove ester and mineral oil without damaging the surface of the part.

The main method of laser cleaning

The first is the laser dry cleaning method, which uses pulsed laser direct radiation purification

Secondly, the laser liquid film method is adopted, that is, a layer of liquid film is deposited on the surface of the substrate first, and then laser radiation is used for decontamination.

Third, the method of laser and inert gas. When laser radiation is applied, the surface of the material is purged with an inert gas.