Why choose a fiber laser cutting machine loading and unloading robot

With fierce competition, diversified demands, and differentiated competition, traditional laser cutting machine manufacturing systems can no longer meet the needs of the stainless steel plate, iron plate and other metal sheet processing market. The production methods of sheet metal processing enterprises have changed, and mass production has gradually been recognized by the market, which makes the flexibility of the sheet metal manufacturing system more and more important. Recently, more and more customers have purchased demand for fiber laser cutting machine loading and unloading robots. Why do you want to buy such an automatic feeding and automatic unloading equipment? The reasons are as follows:

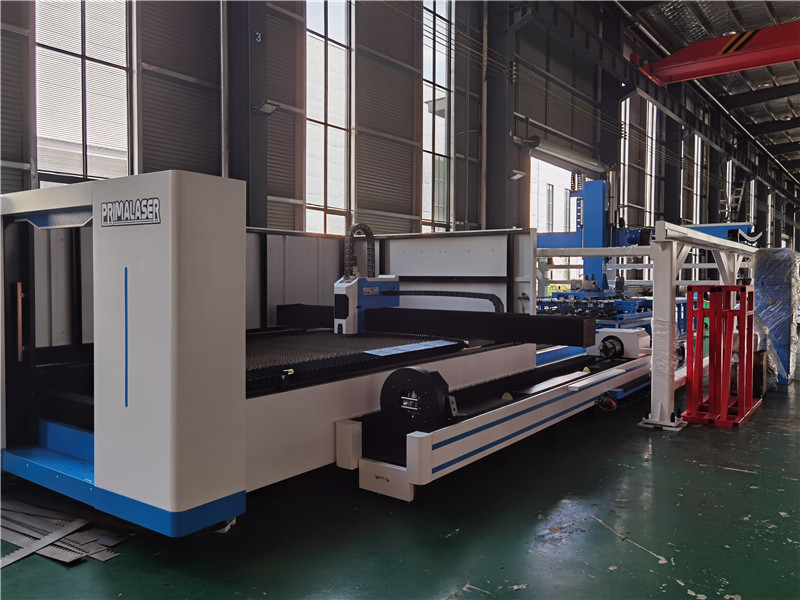

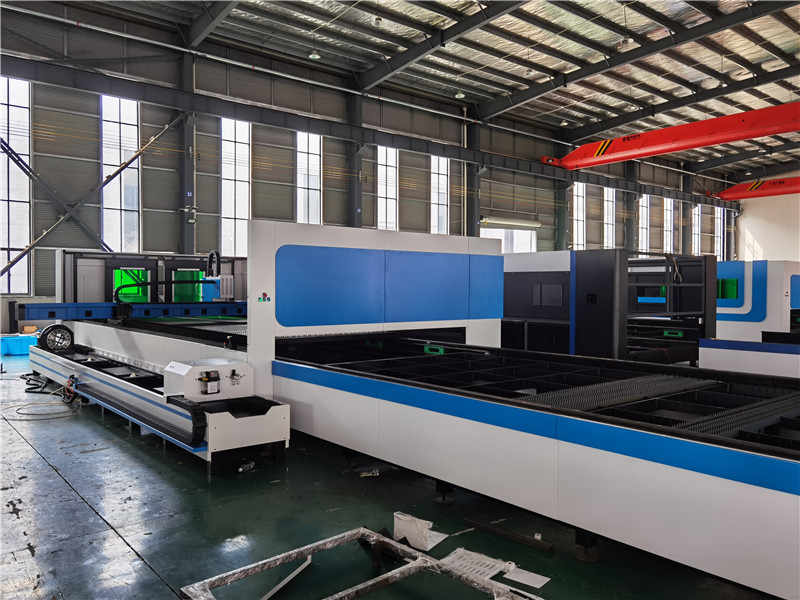

fiber laser cutting machine loading and unloading robot

First of all, the sheet metal fiber laser cutting machine loading and unloading robot can automatically pick up various sheet metal plates that have been cut on the laser workbench. Small workpieces will be placed in a container, and larger workpieces will be placed on a pallet or transport truck for sorting. A large number of workpieces can be sorted through various controllable vacuum suction cups. Features:

- No one is waiting to complete the blanking and sorting of workpieces, automatically identify parts and accurately classify and palletize

- Automatic sheet thickness measurement, sheet separation function and double-layer sheet detection function

- Equipped with offline programming software independently developed by the company, which improves the convenience and efficiency of operation.

- Modular design enables it to be matched with mainstream laser cutting machines in the market and can be customized according to customer needs

Secondly, the robot laser cutting system not only has the characteristics of flexible robot movement and high flexibility, but also has the advantages of laser cutting, such as fast cutting speed, good quality, and narrow kerf, which satisfies the requirements of the development of modern manufacturing. At the same time, it uses robots. Relevant technologies in the field of laser cutting can not only meet the requirements of complex three-dimensional cutting technically, but also help improve the quality of industrial products, while reducing production costs, which can bring huge economic benefits to enterprises.

The metal fiber laser cutting machine automatic loading and unloading system is composed of storage, loading manipulator, unloading manipulator, sorting unit, warehouse management system, and production line operation management system. Achieved:

- Unified management of production cutting tasks

- Improve the utilization efficiency of the laser machine and reduce the standby time

- Reduce the labor intensity of employees and improve on-site labor safety

- Reduce the number of workers and avoid labor shortage

- Improve the on-site environment and enhance the company’s image

- Make basic preparations for the introduction of smart factories in the future

Finally, according to the needs of the customer to provide the workpiece, to confirm the specific configuration, so as to make a quotation. Primapress provides a professional automatic laser loading and unloading machine solution based on the drawings provided by the customer.