what is the normal problem and how to do maintenance for electro-hydraulic synchronous bending machine

Keywords: electro-hydraulic synchronous bending machine

No matter what mechanical equipment is used, such and other problems will occur after a long time of use. Some are more serious problems, and some are relatively simple.

As long as you pay more attention to these problems during normal use and make relevant solutions, you can Up. So do you know what are the common problems?

Common problems are the problems of the sliding block and the guide rail of the bending machine, and the positioning error of the backgauge, and so on.

So everyone knows what aspects of the maintenance and maintenance of the electro-hydraulic synchronous bending machine should be paid attention to at ordinary times?

Let’s take a look at it in detail with the editor below.

Common problems of electro-hydraulic synchronous bending machine:

There are many cases of malfunctions in the use of electro-hydraulic synchronous bending machines. The following editor will introduce a more common problem, let’s take a look.

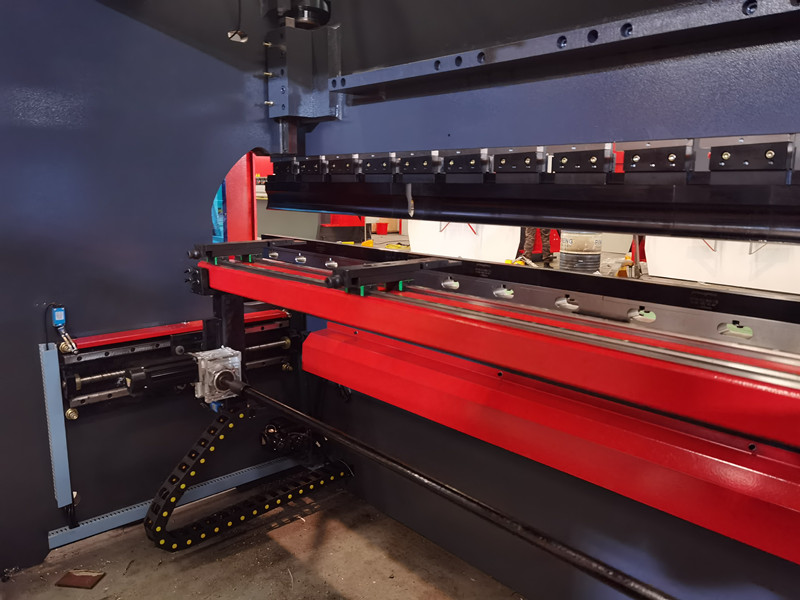

- First of all, the problem of the slider and the guide rail of the electro-hydraulic synchronous bending machine. The vertical movement of the cylinder and

- the vibration of the pressurization for a long time will cause the guide gap to become larger, and the tilt and jitter of the slider up and down will occur,

- which will greatly The damage to the guide rail and the slider liner will seriously affect the accuracy and efficiency of the bending.

- The positioning error of the back gauge. The error of the back gauge has many influences. First of all, the screw rod of the back gauge and the polished rod

- or the linear guide should be cleaned and lubricated regularly. It is responsible for the impurities on the back gauge. Attached to the above, the screw rod and

- polished rod will be damaged for a long time, which will affect the precision positioning of the backgauge. Then the linear guide on the backgauge

- beam and the mold plane have too much deviation in parallelism. This situation needs to be loosened Axis synchronous belt, carefully adjust the

- parallelism tolerance range, and then install the synchronous belt.

3. The looseness of the nut on the connecting rod of the hydraulic cylinder and the slider of the electro-hydraulic synchronous bending machine

will cause the error of the bending angle and the machine can not find the reference point for the recovery.

- When bending short sheet metal, special attention must be paid to the bending in the middle, otherwise the stability and synchronization

- of the torsion axis balance system of the press brake will be affected due to the unbalanced load, and the bending angle will be different on both sides.

Maintenance content of electro-hydraulic synchronous bending machine:

Before machine maintenance or cleaning, the upper mold should be aligned with the lower mold and then shut down until the work is completed.

If you need to start or perform other operations, select the manual mode and ensure safety. The maintenance content is quite a lot, the following is a detailed introduction:

1, hydraulic circuit

A. Check the oil level of the oil tank every week. If the hydraulic system is repaired, it should also be checked. If the oil level is lower than the oil window, add hydraulic oil.

B. The hydraulic oil used in this machine is ISO HM46 or MOBIL DTE25.

C. The oil should be changed after 2000 hours of operation of the new machine, and the oil should be changed after every 4000 to 6000 hours of operation thereafter,

and the oil tank should be cleaned every time the oil is changed.

D. The oil temperature of the system should be between 35℃~60℃ and not exceed 70℃. If it is too high, it will cause deterioration and damage of the oil quality and accessories.

2, filter

A. Each time the oil is changed, the filter should be replaced or thoroughly cleaned.

B. The machine tool has related alarms or other filter abnormalities such as unclean oil, and should be replaced.

C. The air filter on the fuel tank should be inspected and cleaned every 3 months, preferably 1 year.

3, hydraulic parts

A. Clean hydraulic components (substrates, valves, motors, pumps, oil pipes, etc.) monthly to prevent dirt from entering the system, and cleaning agents cannot be used.

- After using the new machine for one month, check whether there is any deformation in the bends of the oil pipes. If there is any abnormality, they should be replaced.

- After two months of use, all fittings should be tightened. The system should be shut down during this work. The pressure hydraulic bending machine includes a support,

- a workbench and a clamping plate. The workbench is placed on the support. The workbench is composed of a base and a pressure plate. The base is connected

- to the clamping plate through a hinge. The base is composed of a housing, a coil and a cover. The coil is placed in the recess of the seat shell, and the top

- of the recess is covered with a cover plate.

When in use, the coil is energized by the wire, and the gravitational force is generated on the pressure plate after the power is energized, so as to realize the clamping

of the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressing plate can be made into a variety of workpiece requirements, and workpieces with side walls can be processed.

The above is what the editor introduces to you about the common problems of electro-hydraulic synchronous bending machine and the content of maintenance

should be paid attention to in peacetime, so if you have other related questions, you can consult us.