What is precision stamping and ordinary stamping

Precision stamping and ordinary stamping are essentially different. Precision stamping refers to various materials stamped by precision punching press machines. These precision stamping pressing parts themselves have higher precision requirements than ordinary stamping, such as terminal strips, USB interfaces, motor stators and rotors. , Air-conditioning fins, EI slices, etc., the demand is large, and the product precision requirements are high. While ordinary stamping does not require too much precision, manufacturers will consider ordinary stamping from the perspective of cost saving.

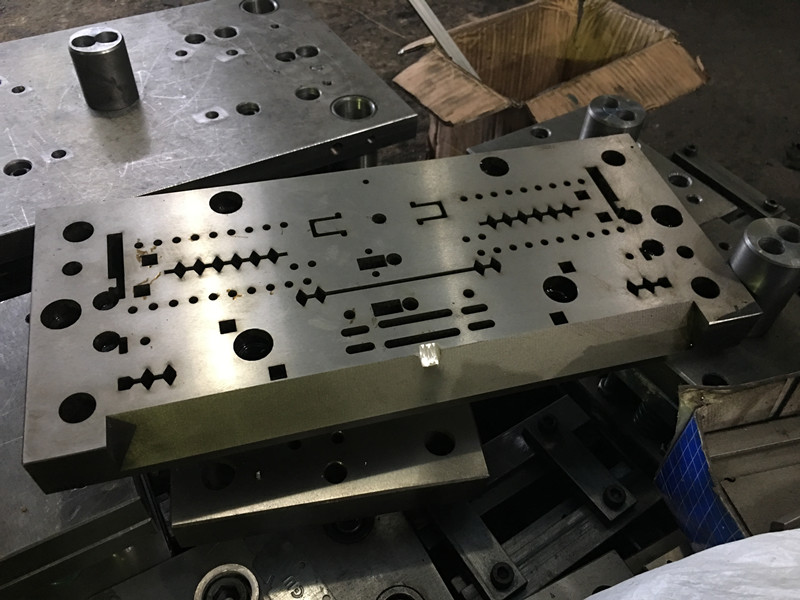

In the production process of precision stamping parts, when stamping coils or forming, it is necessary to consider the appropriate technical matching of precision punches, molds, materials, lubricants, etc.

Precision stamping needs to be produced by a precision punch. The structure, pressure effect and safety device of the punch have the following requirements:

- High rigidity in the vertical and horizontal directions

- The mold installation workbench, when the mold gasket is installed, the deformation is very small

- It is easy to achieve the best working condition

- There must be measures to prevent mold damage. For precision punching machines, in addition to the punching force of the machining center, as a beneficial method to improve the deformation ability of the processed material, there are two auxiliary methods to generate hydrostatic pressure. Pressure generating device. One is the Y-shaped annular protrusion designed on the pressing plate along the contour of the part, because about 50% of the punching pressure is used to press on the material to be processed, which is called the ring gear pressing plate. The other applies 25% of the main blanking pressure to the end surface of the product’s unloader, which is called back pressure. These three pressures do not interfere with each other, and the size of each pressure is synchronized with the forming. It must be suitable for the processing requirements of forming and punching, and can be adjusted arbitrarily. In addition, the processing speed must also be adjusted according to the requirements of the processing object for forming or punching. . The structure of the mold is not only required to be simple and light, but also suitable for use. When processing thick plates, for molds that are prone to deformation, there is no significant deformation due to the use of central support. Even when the workpiece is squeezed into the die during the punching process, if the ejector retreats, the inside of the die is also supported by the center support. If a hydraulic piston is connected to the side of the ring gear pressing plate and the piston moves backward, the inner side of the punching ring pressing plate is still supported by the central support, so the rigidity will not be destroyed at any time.

Although the precision of ordinary stamping is low, it also has its specific market needs. The thickness of the substrate is relatively thick and does not require cutting, cutting, stretching and other processes. The stamping materials are plates, pipes, etc., and the product order quantity is not required. Ordinary stamping can meet the requirements.

What kind of punching machine to choose, customers and friends can choose according to their own stamping characteristics. If the amount of stamping parts is particularly large and the accuracy is high, you can choose a high-precision punching machine when the budget allows. If the precision requirements of the stamping parts are not high, and the stamping is made of ordinary sheet materials, then ordinary punches and low-speed punches can be used to produce stamping parts.