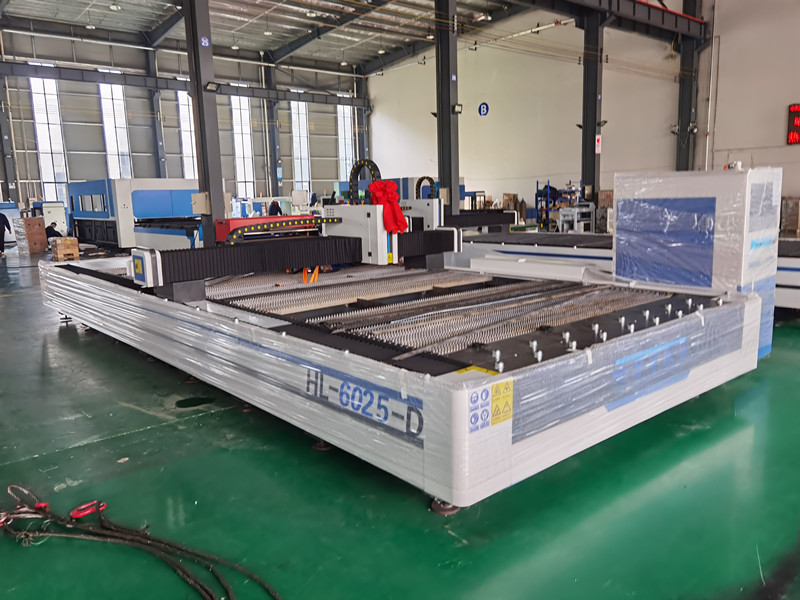

Metal laser cutting machine is a common metal cutting equipment. When using this equipment, you need to choose different auxiliary gas according

to different cutting materials. Let us briefly understand what is needed for metal laser cutting machine. Gas, let’s see…

What gases are required for metal laser cutting machines: At present, the auxiliary gases commonly used in metal laser cutting machines are oxygen, nitrogen, air and argon.

1. When laser cutting, a large amount of heat is generated. When such high heat is concentrated together, the material at the cutting portion is burned,

an oxidation reaction occurs, and the workpiece is easily deformed. Therefore, we need to add some auxiliary gases, commonly used are oxygen, air, nitrogen.

Second, when we need to process stainless steel, we should choose nitrogen. Because nitrogen can prevent the oxidation of the incision, the processed incision

will not be black. Choose high purity when choosing nitrogen.

Third, if it is to process carbon steel, it is necessary to choose oxygen. Oxygen mainly plays the role of combustion support, which can speed up the processing

speed of the workpiece. Of course, the purity of oxygen should be as high as possible.

Fourth, in some processing that is not very precise, we can also choose oxygen, because the use of oxygen is low, and it also has a great auxiliary effect.

5. In addition to the above functions, these auxiliary gases have many functions in common. These gases can blow away the slag produced during

cutting and protect the lens, preventing the slag from sticking to the lens and extending the life of the lens. Air and nitrogen also have a cooling effect that cools the cutting head.

The above is the full content of the gas required for the metal laser cutting machine. I hope this article can help everyone.