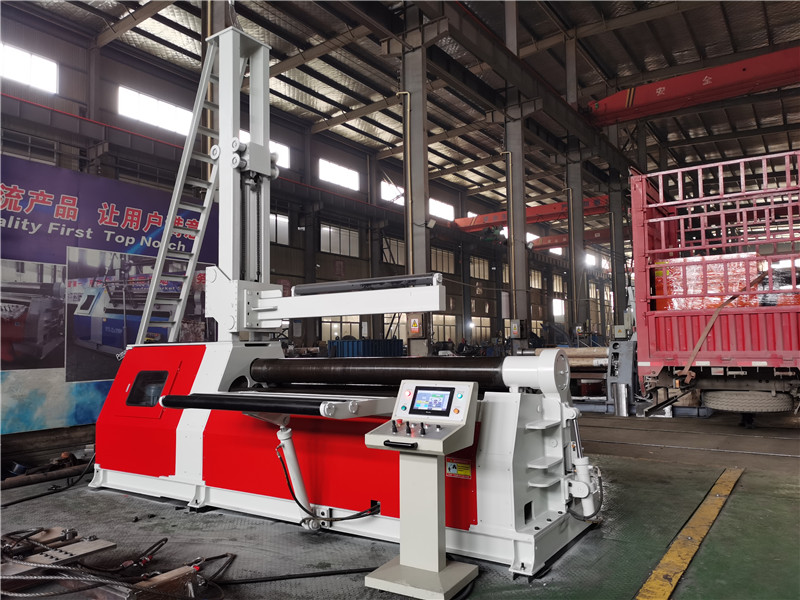

What are the safe operation and maintenance process skills of the sheet metal plate rolling machine?

- The sheet metal plate rolling machinemust be managed by a dedicated person.

2. The operator must be familiar with the structural performance and use of the sheet metal plate rolling machine, and can only operate after the approval of the responsible manager.

- Check carefully whether the safety device is in good condition before starting the machine.

4. During operation, it is strictly forbidden to put hands and feet on the rollers, transmission parts and workpieces.

5. After work is interrupted, the clutch should be turned to neutral.

6. Multi-person collaborative operations must be directed by a special person.

7. Overwork is strictly prohibited.

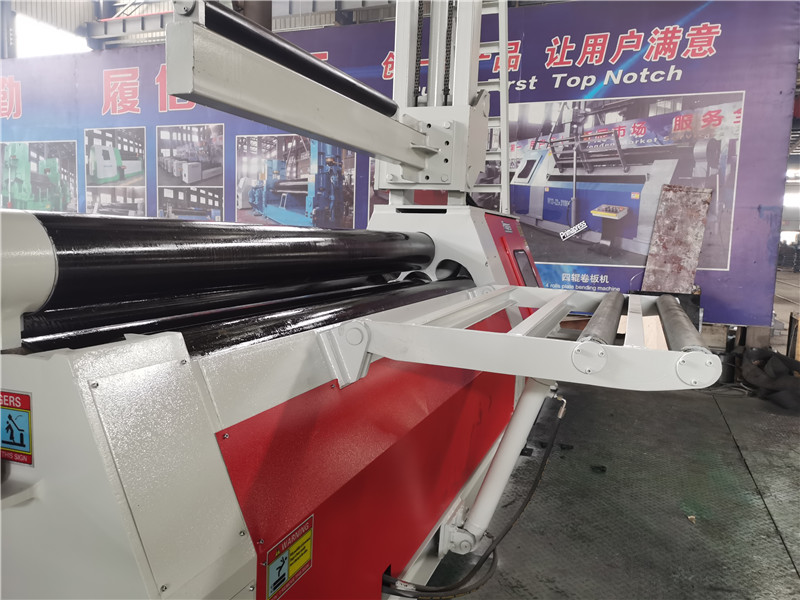

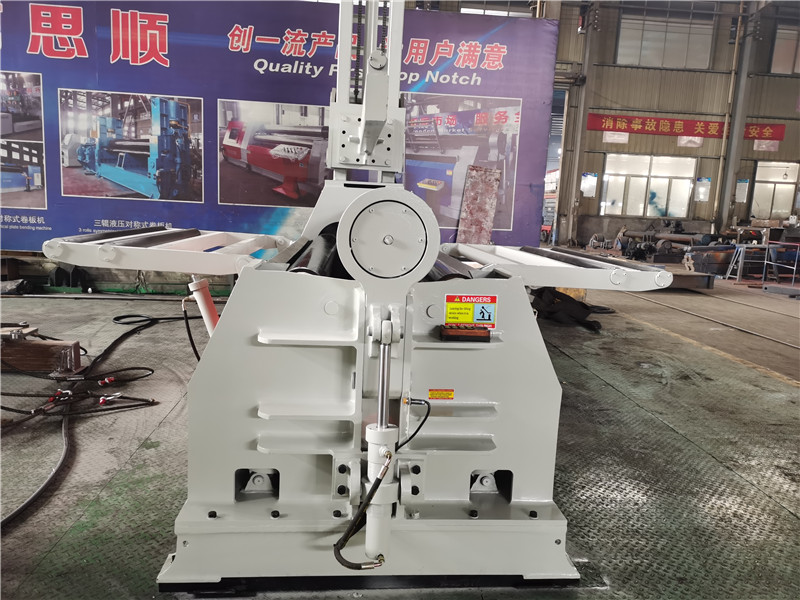

8. The tilting reset of the lifting and turning bearing of the upper roller and the balance of the upper roller must be carried out after the main drive is stopped.

9. It is forbidden to pile up workpieces and sundries in the workplace, so as to keep the machine tool and the site clean at all times.

10. After the operation is completed, the power supply should be cut off and the power supply box should be locked.

What problems should be paid attention to in the maintenance of sheet metal bending machine

1. According to the provisions of the machine lubrication diagram, add oil to each oil cup lubrication and manual lubrication points as required.

2. Roll the plate according to the parameters specified by the sheet metal plate rolling machine, the thickness of the coil is 20mm, the maximum length is 2500mm, and the yield limit of the coil material is less than 250Mpa.

3. After turning on the power, carry out the movement of the lower roller in both positive and negative directions and the upper roller’s lifting movement, and check whether each movement is abnormally stuck.

4. Strictly operate in accordance with the coil processing procedures and operating methods, and pay great attention to the safe operation of the equipment when the upper roller is lifted to the limit position.

5. When the main drive is stopped, the upper roller can be raised and lowered, the overturned bearing can be tilted and reset, and the upper roller can be tilted.

6. During operation, if any irregular noise or impact is found, it should be shut down immediately for inspection.

7. During the operation, all personnel must coordinate with each other and obey the instructions of the person in charge of the rolling plate. Without a password, it is forbidden to start the machine.

8. When carrying out the plate rolling operation, pay great attention to the fact that the hand is pressed by the steel plate and the steel plate is rolled together.

9. When lifting the steel plate or drum with a crane, be careful not to collide with the machine.

After the coil is finished, the site should be cleared after the work is completed, and the equipment should be maintained and the power supply should be turned off in time.