What are the classification and structure of CNC plate bending machine and the characteristics of electro-hydraulic servo CNC plate bending machine?

The CNC plate bending machine can be said to be a kind of equipment that can bend thin plates. Nowadays, there are different classifications for its properties, and the overall composition is relatively simple.

CNC plate bending machines can be mainly divided into three types: manual CNC plate bending machines, hydraulic CNC plate bending machines, and CNC CNC plate bending machines.

- Manual CNC plate bending machine: It can be divided into two types: mechanical manual CNC plate bending machine and electric manual CNC plate bending machine.

- Hydraulic CNC plate bending machine:

(1) According to the synchronization method, it can be divided into three types: torsion shaft synchronization, machine-hydraulic synchronization and electro-hydraulic synchronization.

(2) According to the movement mode, it is divided into two types: up-moving and down-moving.

Structure description of CNC plate bending machine

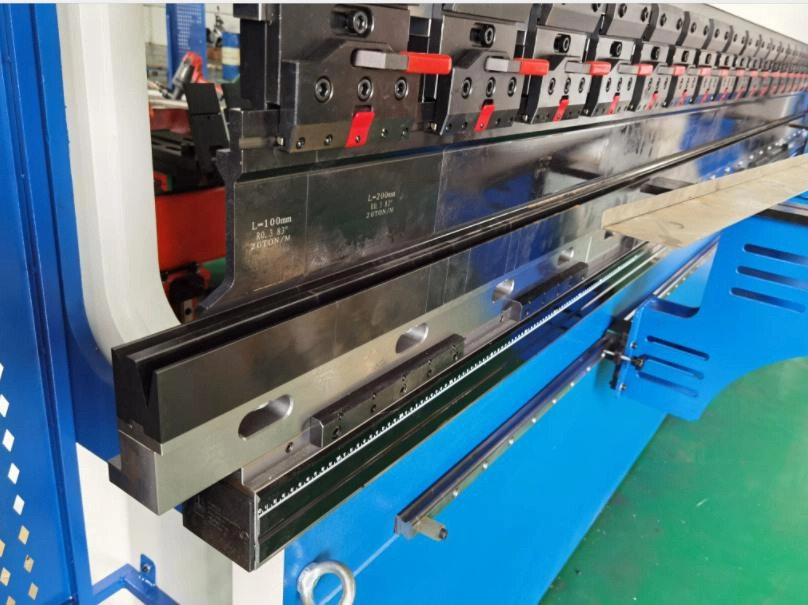

- Slider part: It is mainly composed of a slider, an oil cylinder and a mechanical stop fine-tuning structure. The left and right cylinders of the slider of the CNC sheet bending machine are fixed on the frame, and the piston is driven by hydraulic means to move up and down. .

- The worktable part: it is operated by the button box, which allows the motor to drive the material stopper to move forward and backward, and the numerical control system controls the moving distance.

- Synchronization system: This part is a synchronization mechanism composed of torsion shafts, joint bearings, swing arms and other frameworks. Because the overall structure is relatively simple, the performance is stable and reliable, and the synchronization accuracy is relatively high.

- Material stopper mechanism: The motor drive is adopted, specifically, the synchronous movement of the two screw rods is driven by chain operation, and the numerical control system of the CNC plate bending machine controls the size of the stopper.

The performance characteristics of electro-hydraulic servo CNC CNC plate bending machine:

Regarding the performance characteristics of the electro-hydraulic servo CNC CNC plate bending machine, the following is a detailed introduction:

- The electro-hydraulic servo CNC plate bending machine adopts the hydraulic convex automatic compensation system to solve the influence of the deformation of the slider during the bending process on the quality of the workpiece. The amount of compensation is automatically adjusted by the numerical control system, which is convenient and accurate.

- The electro-hydraulic servo CNC plate bending machine adopts a fully functional back gauge mechanism, which can optionally control multiple back gauge shafts. Functional parts in the back gauge. Such as guide rails, lead screws, bearings, etc. are all imported originals to ensure the accuracy of the back gauge.

- The body of the electro-hydraulic servo CNC plate bending machine adopts an integral welding structure, which is convenient for transportation and processing, and can ensure the overall accuracy of the machine tool.

- The fuselage, slider and other important components of the electro-hydraulic servo CNC plate bending machine are analyzed by ANSYS finite element analysis software to ensure the reliability of the machine tool.

- The hydraulic system of the electro-hydraulic servo CNC plate bending machine adopts an integrated control system imported from Germany, which reduces the installation of pipelines, improves the working stability of the machine tool, and has a beautiful and simple appearance.

This is the introduction of the advantages and performance characteristics of the electro-hydraulic servo CNC plate bending machine. It can be seen that the CNC plate bending machine itself still has many advantages, mainly in the equipment structure. Some foreign parts, after all, in terms of CNC plate bending machines, the development of foreign countries is more advanced.