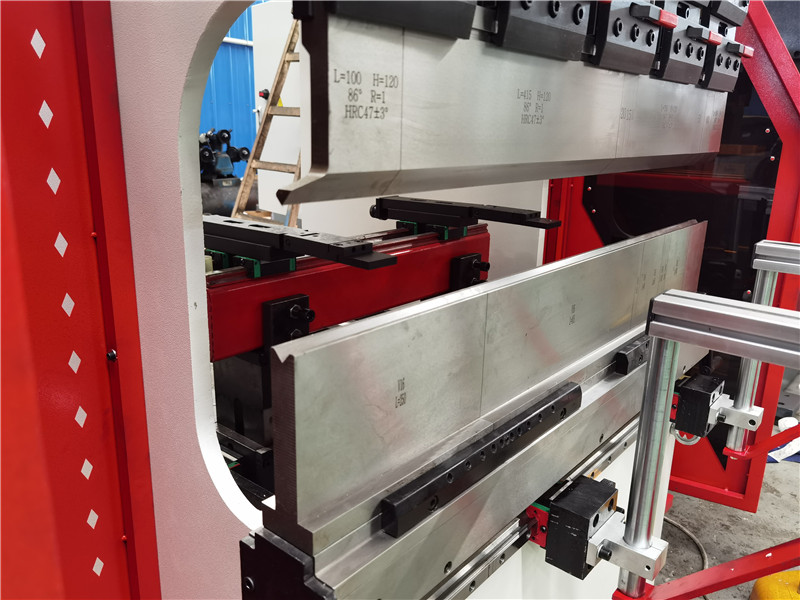

Types and operating principles of torsion shaft synchronous cnc press brake bending machines

In modern life, people often use some bending machines for processing and production. There are several types of torsion axis synchronous bending machines. Torsion axis synchronous bending machines have the same advantages as hydraulic servo CNC bending machines cnc press brake . How to distinguish them? What are the working modes of the torsion axis synchronous bending machine? Join us below to learn more about it! The following is an introduction to the “type introduction and operation principle of torsion axis synchronous bending machine”.

[How to distinguish between torsion axis synchronous bending machine and hydraulic servo CNC bending machine cnc press brake ]If it is two bending machines of the same type, other aspects are the same, except that one uses servo CNC synchronization, and the other uses torsion axis synchronization, but the aspects presented are also different, such as structure, work efficiency, etc.

The difference between the servo CNC synchronization of the bending machine and the synchronization of the torsion axis is that the structures on both sides of the bending slider to ensure synchronization are different. The torsion axis synchronous bending machine mainly relies on the forced synchronization of the mechanical balance axis, so the synchronization accuracy is low, there is no error feedback, and the bending slider has poor anti-eccentric load capacity.

The electro-hydraulic servo CNC bending machine cnc press brake relies on the synchronization of the servo synchronous proportional valves on both sides, which not only has high synchronization accuracy, but also has real-time error feedback. .

The difference between the hydraulic servo CNC bending machine cnc press brake and the torsion axis synchronous bending machine is reflected in the work efficiency, which is closely related to the speed of the slider, the function of the CNC system, and the efficiency of the initial test of the workpiece. The opening height of the slider of the torsion axis synchronous bending machine is fixed, so each time it is opened, it must move from the high point to the low point, and the opening height is too small, so the overall work efficiency is not high.

The opening height of the slider of the electro-hydraulic servo CNC synchronous bending machine can be digitally controlled by the grating ruler, instead of returning to the high point every time, which effectively saves time and improves the processing efficiency. From this point of view alone, the working efficiency of the electro-hydraulic servo synchronous bending machine is better.

In contrast, the CNC system software used in the electro-hydraulic servo CNC synchronous bending machine is highly integrated, so workers can program the required workpieces more intuitively and quickly, and the operation is simple. Unlike the torsion axis synchronous bending machine, which requires repeated calculations to program the program.

【How the torsion axis synchronous bending machine works】

- The synchronous layout of the slider of the bending machine refers to the forced synchronization of the torque axis.

- Reference constraint block organization, quiet indeed.

- Refers to a fully welded steel structure with sufficient strength and stiffness.

- The hydraulic cylinder is at both ends of the transmission, the saw is placed on the slider, and the slider is launched in a straight line.

- Traps for wedge deflection compensation, thus ensuring high precision bending.

- The slider line is agile for anxiety adjustment, manual fine-tuning, and exposure counter.

After the bending machine is used for one month, check the damaged place of each oil pipe, there is no shape, such as abnormality, it should be changed, after two months, the connection of all parts should be tightened, the progress and service should be closed, and the system should be free of pressure.

The hydraulic press brake contains the support, the table and the clamping plate, the work is mounted on the bracket, the table is supported by the base and the clamping plate, the setting process hinged clamping plate is continued, by the housing, and a cover plate closes the coil, in the fall of the fall In a shell coil, the top end is covered with a cover plate.

When the pressure plate is selected by the coil, the burst of gravity, thus realizing the pressure plate and clipping to the plate base. The reason is electromagnetic force tongs, which will be good for multiple parts boards, and can polish the prosperous sidewall of the workpiece.

The above introduction about “how to distinguish between torsion axis synchronous bending machine and hydraulic servo CNC bending machine” and “the working method of torsion axis synchronous bending machine”, I hope you can understand the “type introduction of torsion axis synchronous bending machine and How It Works” to help.