The Structure of Servo turret punching CNC Punching Machine and Its Punching Accuracy

Servo turret punching CNC punching machine is widely distributed as a general-purpose machine. Its structural composition determines its functional effect. There is also a big difference in the precision control of punching. , let’s take a look!

The structure of servo turret punching CNC punch press:machine

- Servo unit, driving device and measuring device: ensure sensitive and accurate tracking of CNC device commands, including feed motion commands and spindle motion commands. Servo motors, linear guides, ball screws, couplings, pneumatic components and electrical components are imported brands to ensure the accuracy and stability of the equipment.

- PLC, equipment I/O circuits and devices: accept the M, S, T commands of CNC, decode and convert them into corresponding control signals, and control auxiliary devices to complete the corresponding switching actions of the equipment; accept the operation panel and equipment The I/O signal on the side is sent to the CNC device, and after its processing, the output command controls the working state of the CNC system and the action of the equipment.

- Operation panel: a tool for the operator to issue instructions to the servo turret punchingCNC punching machine – a daily computer. It adopts the most popular Windows7/10 computer operating system, which realizes the automatic conversion of AutoCAD graphics and the processing program, and the operation is flexible and convenient. It is not troublesome to learn, basically it is easier to learn with a bit of cad foundation.

- CNC system. The main introduction is the core of the CNC system – the CNC device. Perform corresponding processing (such as motion trajectory processing, servo turret punchingCNC punch input and output processing, etc.) according to the input part processing program, and then output control commands to the corresponding execution components (servo unit, drive device and PLC, etc.)

- Control medium and input and output equipment: The control medium is the medium for recording the part processing program, and the input and output equipment is the interaction device between the CNC system and the external equipment. Mainly the control unit.

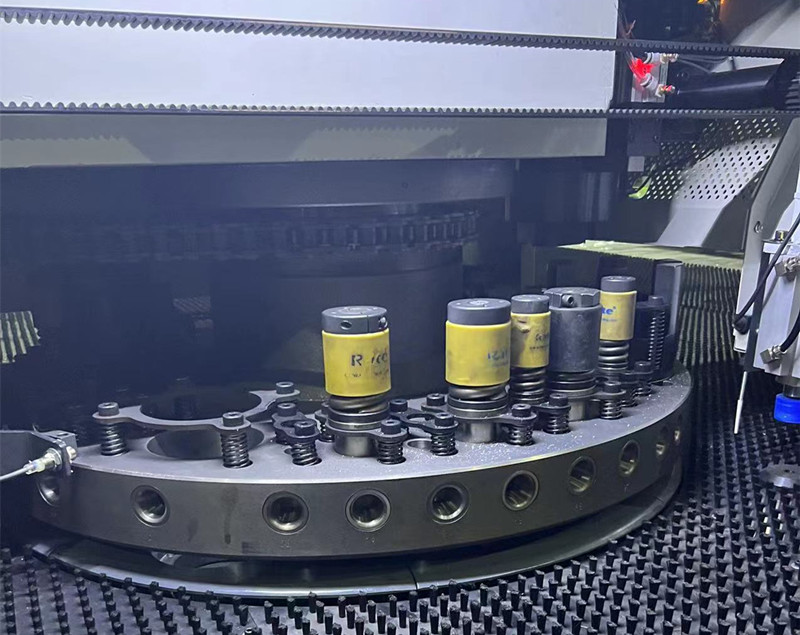

- Mechanical equipment: The main body of CNC equipment is the executive component that realizes manufacturing and processing. The whole bed is tempered and then subjected to vibration aging treatment to effectively eliminate internal stress.

The punching accuracy detection method of the servo turret punching CNC punch press machine :

- The parallelism of the slider stroke to the task table.

The specific detection method of punching accuracy is to use a dial gauge to move longitudinally and laterally on the bottom surface of the slider and the task table, and the large difference between the dial gauge readings is the measured value. The tolerance is 0.13mm in the length of 1000mm front and rear. For open hydraulic presses, only the front end of the slider is allowed to deviate downwards. For sweepers, the tolerance is 0.10mm in the length of 1000mm left and right.

- The flatness of the punching table and the bottom surface of the slider.

The specific detection method is to place the inspection surface of the flat ruler on the hydraulic press table in different directions, and use a feeler gauge to measure the parallelism between the inspection surface of the flat ruler and the task table. . The tolerance on a 1000mm length is typically 0.05mm.

- The parallelism of the center line of the punching die shank hole to the stroke of the slider.

Pull out a test rod from the die handle hole of the slider, fasten it on the task table and place a dial indicator so that the thimble of the dial indicator is in contact with the surface of the test rod, so that the slider moves up and down slowly, and the dial indicator is read out. Large difference in meter readings. 0.05mm tolerance on 300mm stroke.