The scope of use and main components of metal pneumatic power press punches machine

Pneumatic punching machine is a kind of high-speed punching equipment with high punching accuracy and high speed. The compressor is used to generate gas. Pneumatic punching machine adopts photoelectric protection technology. It uses pneumatic clutch brake type punching equipment to realize computer counting and programming. Cooperate with each other to improve work efficiency. Let’s take a look at the scope of use of pneumatic punches.

- Metal punching industry: Pneumatic punching machines are widely used in metal punching industry, and can be applied to the punching field of various metal and non-metal pipes and plates.

- Machinery industry: applicable to the processing and production of stamping parts, stamping processing, metal stamping parts, metal stamping parts, automobile stamping parts, drawing parts, metal drawing parts, and stamping sheet metal parts in the machinery industry.

- Household items: most of the furniture items in daily life are processed and produced by pneumatic punches, such as electronics, communications, electrical appliances, lighting, toys, chassis, furniture, sports equipment, barbecue tableware hardware, lighting hardware, electronic hardware, Chassis cabinets, kitchen utensils, hinges, split pins, spring pins, pliers, dried fruit pliers, packaging materials, stickers, mobile phone films, gaskets, cushions, aluminum parts, terminals, speaker nets and other daily necessities.

- Road traffic: In particular, the production of auto parts is inseparable from pneumatic punches, transportation supplies, automobiles, protective equipment, automobiles and motorcycles and accessories communication products.

- Office supplies: power cabinets, air-conditioning parts, printers, copier racks and various sheet metal.

The pneumatic punch clutch adopts a composite dry pneumatic clutch, the flywheel has a built-in bearing and a clutch, and the sealing plate is fixedly combined. When the control button is pressed, the air is pressed into the clutch by the solenoid valve, and the power of the flywheel is transmitted to the crankshaft for work. Select the control panel kinetic energy key It can realize inching and continuous work of stroke.

What are the main component structures of pneumatic punches

Pneumatic punch presses work by transmitting the inertial force of the flywheel to the crankshaft, connecting rod, and slider by a pneumatic clutch. The crankshaft connecting rod is rigid, so the movement of the slider is mandatory. At the same speed, the number of strokes and the movement curve of the slider They are all fixed. The editor will share what are the main component structures of pneumatic punches and learn more about pneumatic punches.

- The fuselage, cast into a single piece with the worktable, the slider moves up and down in the guide rail on the fuselage, the gap between the guide rail and the slider is adjusted by the top wire, and the cap is tightened after adjustment.

- The clutch, pneumatic punching machine adopts a composite dry pneumatic clutch, the flywheel has a built-in bearing and a clutch, and the sealing plate is fixedly combined. When the control button is activated, the solenoid valve presses air into the clutch, and the power of the flywheel is transmitted to the crankshaft for work. Select the control panel The kinetic energy key can realize the continuous work of the stroke.

- The slider, the connecting rod and the ball head adjustment screw convert the circular motion of the crankshaft into reciprocating motion. The ball head screw can adjust the clamping force and adjust the height of the mold. The lower end of the slider is provided with a mold handle hole, which can be tightened during decoration. For solid molds, large molds can use the template holes on both sides and the slider adjustment holes are equipped with a return device, and adjust the ejector seats on both sides according to the height of the mold to realize the stripping work.

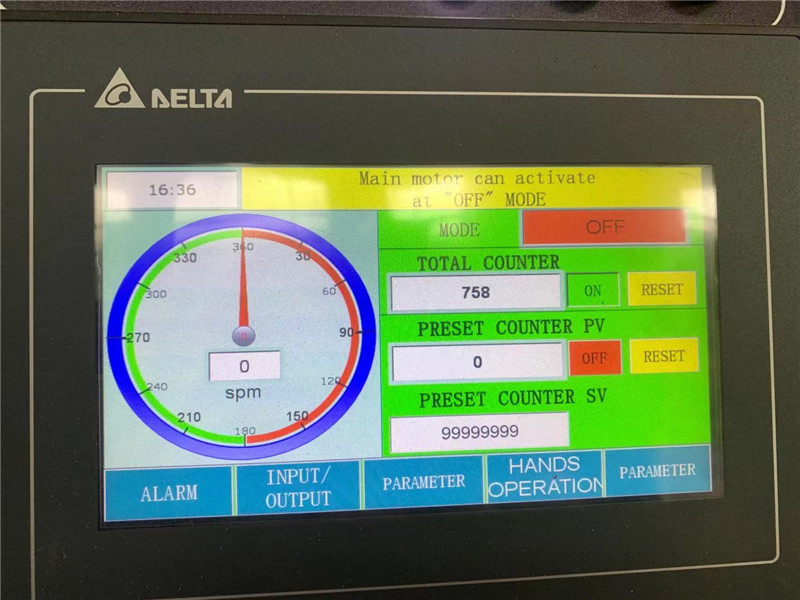

- The operating mechanism of the pneumatic punch press is controlled by a microcomputer, and the status mode is displayed on the panel. When the status bar displays an inch movement, the machine can be synchronized with both hands to start the machine.

Pneumatic punching machine has simple structure and low production cost. It adopts pneumatic technology to realize that one air compressor can supply multiple pneumatic punching machines at the same time. The operation is simple. The foot switch is used to control the solenoid valve. The structure is simple and the failure rate is low.