The relationship between thickness and power of sheet metal fiber laser cutting machine

In recent years, the rapid development of my country’s high-speed rail, nuclear power, shipbuilding, petrochemical and aerospace industries has put forward higher demand for laser cutting processing equipment and technology. The general trend is Development in the direction of larger, thicker cutting, brighter cross-section, and straighter.

As a result, from 6000W to 8000W, and then to the 10,000-watt sheet metal fiber laser cutting machine that once seemed out of reach, the power of the sheet metal fiber laser cutting machine

has broken our imagination step by step. The thickness of the previous fiber laser cutting sheet is limited to carbon steel within 20mm and stainless steel within 12mm, while the 10,000-watt fiber laser cutting machine for metal sheet can cut aluminum alloy sheets up to 40mm and stainless steel sheets up to 50mm. When cutting stainless steel sheets with a thickness of 3~10mm, the cutting speed of a 10kW sheet metal fiber laser cutting machine is more than twice that of 6kW; at the same time, the 10,000-watt sheet metal fiber laser cutting machine can reach 18% in carbon steel cutting applications. ~20mm/s fast bright surface cutting is twice the ordinary standard cutting speed; carbon steel within 12mm can also be cut with compressed air or nitrogen, and the cutting efficiency is six to seven times the speed of oxygen cutting carbon steel.

Data shows that, in terms of 8mm stainless steel, the speed of 6kW compared to 3kW metal sheet fiber laser cutting machine has increased by nearly 400%. In terms of 20mm thick stainless steel, the speed of 12kW is 114% higher than that of 10kW.

From the perspective of economic benefits, the price of a 10,000-watt sheet metal fiber laser cutting machine is less than 40% higher than that of a 6kW machine tool, but the output efficiency

per unit time is more than twice that of a 6kW machine, and it saves In addition to labor and space, it is favored by the bosses of laser processing enterprises.

The target of the sheet metal fiber laser cutting machine includes stainless steel, carbon steel, alloy steel, aluminum sheet, silver, copper, titanium and other sheet metal materials.

For different sheet metal materials, the cutting thickness of different power sheet metal fiber laser cutting machines has a great relationship with the cutting material. 1000 watts, 2000 watts…How thick can metal sheet fiber laser cutting machines of various powers be cut?

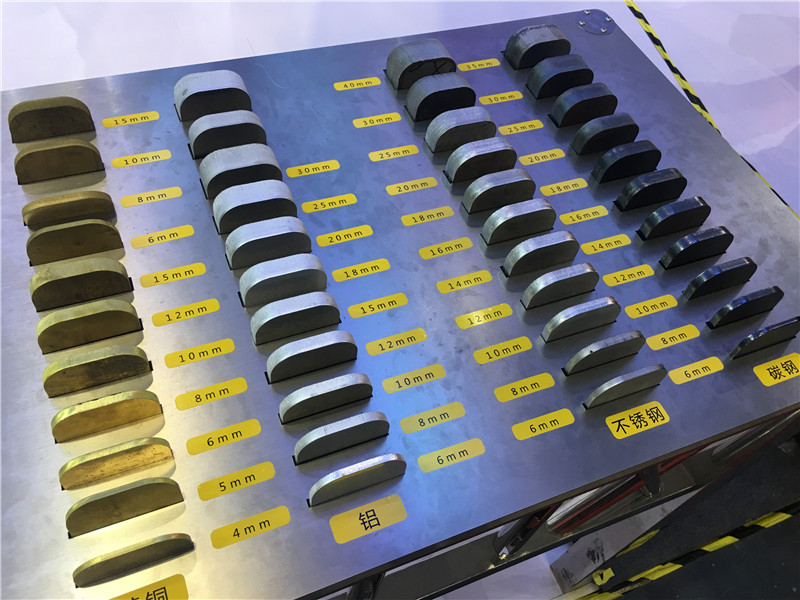

Thickness and power of sheet metal fiber laser cutting machine

Generally speaking, the thickness limit value of different metal sheet fiber laser cutting machine power cutting various materials is as follows:

(For reference only, the actual cutting capacity is also related to the quality of the cutting machine, cutting environment, auxiliary gas, cutting speed and other factors)

- The maximum cutting thickness of different materials by 1500W fiber metal sheet fiber laser cutting machine: the maximum thickness of carbon steel is 15mm; the maximum thickness

- of stainless steel is 7mm; the maximum thickness of aluminum plate is 4 mm; the maximum thickness of copper plate is 4mm;

- 1000W fiber metal sheet fiber laser cutting machine different material cutting maximum thickness: carbon steel maximum thickness 10mm; stainless steel maximum thickness 5mm; aluminum plate maximum thickness 3mm; copper plate maximum thickness 3mm;

- The maximum thickness of 2000W fiber metal sheet fiber laser cutting machine for cutting different materials: the maximum thickness of carbon steel is 16mm; the maximum thickness of stainless steel is 8mm; the maximum thickness of aluminum plate is 5mm; the maximum thickness of copper plate is 5mm;

- 3000W fiber metal sheet fiber laser cutting machine different material cutting maximum thickness: carbon steel maximum thickness 20mm; stainless steel maximum thickness 10mm; aluminum plate maximum thickness 8mm; copper plate maximum thickness 8mm;

- 6000W laser cutting of stainless steel is up to 20mm, but the quality of the cutting surface above 14mm is not guaranteed, and the cutting surface below 12mm is definitely bright surface cutting. The cutting capacity of 8000W will be better, but the price is also higher.

In the actual application process, the cutting ability of the fiber metal sheet fiber laser cutting machine is also related to the quality of the cutting machine, laser type, cutting environment,

cutting speed and other factors. The use of auxiliary gas can also improve a certain cutting ability, so there is no An absolute standard judges its cutting thickness. For example, the cutting of carbon steel mainly relies on oxygen combustion, and the cutting of stainless steel mainly relies on power. Generally, the 1000w fiber metal sheet fiber laser cutting machine can cut

carbon steel plates of about 10mm, and stainless steel plates are slightly difficult to cut. If the cutting thickness is to be increased, the edge effect and speed must be sacrificed.