The principle and difference of 2D/3D metal wire forming machine

Steel wire bending machine is a kind of metal wire bending machine. It can be bent into samples for steel wire, stainless steel wire and metal metal wire. Their working principles are almost the same. We will understand in this article. Let’s take a look at the working principle of the steel wire bending machine.

1. The wire feed wheel is driven by a precision servo motor to rotate, and the professional metal wire bending machine computer system is used to control each driver to perform each step of forming. The servo motor slow-up and slow-down curve and the servo motor speed can be modified as needed, eliminating mechanical transmission The impact of this ensures that the actual transmission wire length is consistent with the theoretical calculation length;

2. In the design budget, the length of each MM has been divided into 10 pulses, which further ensures that the length accuracy setting and the wire feeding accuracy can be controlled at 300±10 wires;

3. Adjustable servo shearing can ensure the neatness of the circle cut, and both the cutting time and the retraction time can be directly modified on the text display;

4. It is designed with manual slow feeding and slow return functions, which is easy to operate and reduce material loss.

5. The production can realize the angle without any change at the slowest speed, and the production stability is better.

6. Important parts such as bearings and gears are imported from Taiwan, with a warranty of 8760 hours, and the equipment is durable and reliable.

7. High precision, can make metal wire forming products within the range of 2.0-14 mm wire diameter, and the error is reduced to 0.1 mm.

8. The supporting use of the steel wire butting machine makes the machine’s wire change operation more convenient.

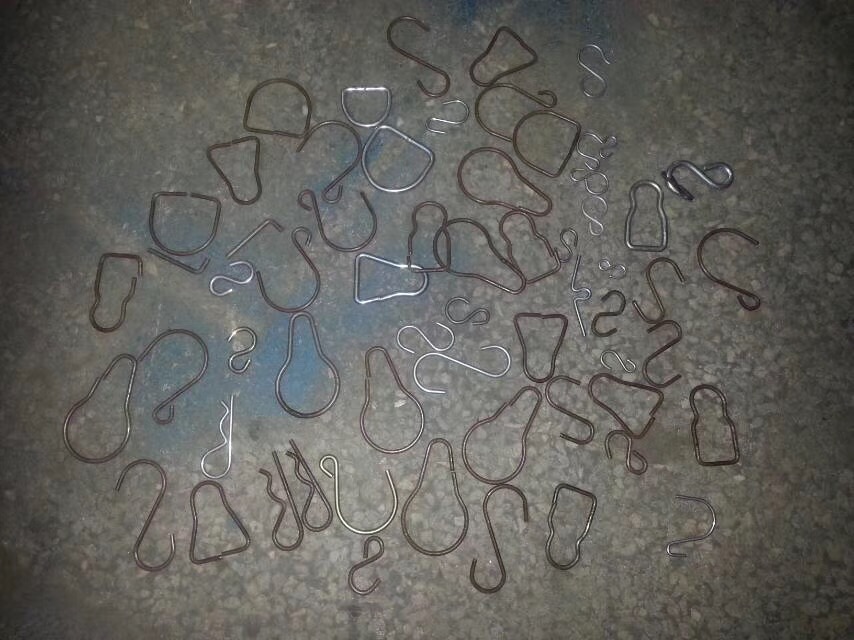

Metal wire forming machine has gradually developed from 2D to 3D metal wire forming machine. Its efficiency is much higher than that of 2D forming machine, and it has been trusted by more and more manufacturers. Therefore, this article will share with you 2D/3D metal wire forming machine. How to tell.

1, 2D metal wire forming machine:

1) The debugging of the metal wire forming machine is simple, and the products made are relatively simple.

2) It can only bend a single-type product with a flat surface, which has certain limitations;

3) Generally, the product line diameter is relatively small, and the function is not too powerful;

2, 3D metal wire forming machine:

1) It can produce products with three-dimensional space and multiple faces;

2) It has a certain degree of flexibility and can process and produce flat products, which covers the functions of a 2D metal wire forming machine. At the same time, it can also bend and shape products in a three-dimensional space;

3) The target product line diameter can be made from small to large, the small diameter is 3mm, the large diameter is 12mm; the function is more powerful.

4) Able to do multi-dimensional, multi-angle and multi-face bending forming, so as to meet the different needs of different customers, with higher product accuracy, debugging and processing, and more technical content;

However, different customers produce different products, so the choice will also be focused. If the product produced by the same customer has both 2D and 3D products, and the product line diameter is relatively large, then you can choose a 3D metal wire forming machine, which can reduce costs to a certain extent. If the strength is good, the production volume is very high. Large, fixed product type or model, small product line diameter, large volume of three-dimensional and flat products, you can consider 2D and 3D models to be purchased and put into use separately.