The importance of CNC bending machine molds and how to produce high-precision cnc press brake bending machines?

In recent years, the competition in the manufacturing industry around the world has become more and more fierce. The ability of enterprises to provide customers with personalized high-quality products with high efficiency and low consumption in the shortest time possible has become a symbol of enterprise competitiveness.

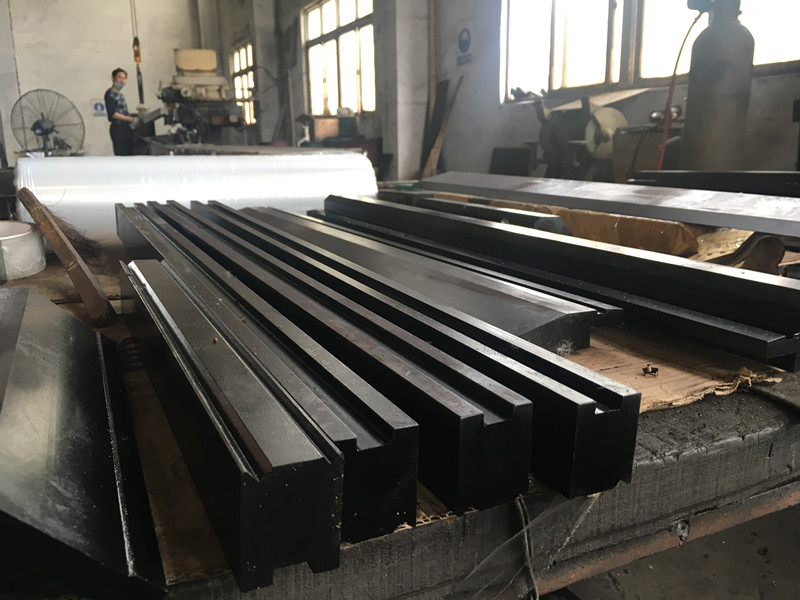

CNC bending machine mold is very important. The quality of CNC bending machine mold will directly affect product quality, output, cost, the cycle of new product production and old product replacement, the speed of enterprise product structure adjustment and market competitiveness. Therefore, the economic situation has put forward higher and higher requirements for the quality of CNC bending machine molds. So how can we improve the quality of CNC bending machine mold more reasonably?

The quality of CNC bending machine mold is not a simple topic, it includes the following aspects:

Product quality: product size stability, conformity, product surface finish, product material utilization, etc.

Service life: On the premise of ensuring product quality, the number of work cycles that can be completed by the CNC bending machine mold or the number of parts produced.

The use and maintenance of CNC bending machine molds: whether it is the most convenient to use, easy to demould, and the production auxiliary time is as short as possible.

Maintenance costs, maintenance periodicity, etc.

Don’t just look at the price, consider the quality, cycle and service in an all-round way

There are many types of CNC bending machine molds, which can be roughly divided into ten categories. According to different requirements of parts material, physical and chemical properties, mechanical strength, dimensional accuracy, surface finish, service life, economy, etc., different types of CNC bending machine molds are selected for forming.

High-precision CNC bending machine molds need to be processed by high-precision CNC machine tools, and CNC bending machine mold materials and molding processes have strict requirements, and CAD/CAE/CAM CNC bending machine mold technology needs to be designed and analyzed. Some parts have special requirements during molding, and CNC bending machine molds also need to use hot runners and gas-assisted molding.

Primaprss believes that manufacturers should have CNC, EDM, wire cutting machine tools and CNC copy milling equipment, high-precision grinding machines, high-precision three-coordinate measuring instruments, computer design and related software. Generally, large-scale stamping CNC bending machine molds should consider whether the machine tool has a blank holder mechanism, or even edge lubricants, multi-function bit progression, etc. In addition to stamping tonnage, sprinting, feeding devices, machine tools and mold protection devices for CNC cnc press brake bending machines should also be considered.

In the bending process of the bending machine, in terms of the current technology, the biggest problem is how to reduce the preparation time before the actual processing, especially when the product needs to be repeatedly processed. For the first processing, in addition to confirming the drawings, it is also necessary to consider the processing mold, the bending sequence of the workpiece, the program input and other links. However, in the actual processing, these factors must be considered comprehensively, there can be no omission, and it takes a lot of time. Long, if the same workpiece needs to be processed repeatedly next time, the last processing programming information cannot be effectively called, and the programming can only be re-programmed to repeat the same work, which is also called “secondary repeated operation”. In this case, it is A great waste of time and labor, repeated consumption, resulting in a decrease in the processing efficiency of the bending machine.

Therefore, in order to avoid this situation, and to better improve the processing efficiency of the bending machine, the processing information of the product can be produced, stored, and used by combining the three to carry out virtuous recycling to completely solve the above problems. question. And through this mode, the processing program and data can be flexibly applied at any time, avoiding repeated work, and improving the actual processing mode. It can be said that there are many benefits.