The characteristics of the two-roll plate rolling machine and the difference from the four-roll plate rolling machine

Two-roll plate rolling machine is a kind of work roll for bending and forming of plate, and it is an important processing equipment. When the plate machine is working, through the action of external forces such as liquid pressure and mechanical force, the work rolls are moved to bend or bend the plate. According to the rotation movement and position changes of different shapes of the work rolls, elliptical parts, arc parts, cylindrical parts and other parts can be processed.

1. The processing speed of the two-roll coil winding machine is fast;

2. The two-roller plate coiler performs high-precision forming in one stroke;

3. Even if the slab is processed by punching, cutting, embossing, etc., it will not produce cracks and irregular warping;

4. The slab of the two-roller rolling machine will not wrinkle the slab and cause scratches on the surface of the workpiece;

5. If the rolling volume of the double-roller plate rolling machine is large, even if the distance between the two rollers changes and the diameter of the part does not change, the equipment accuracy is not very high, and simple equipment is used.

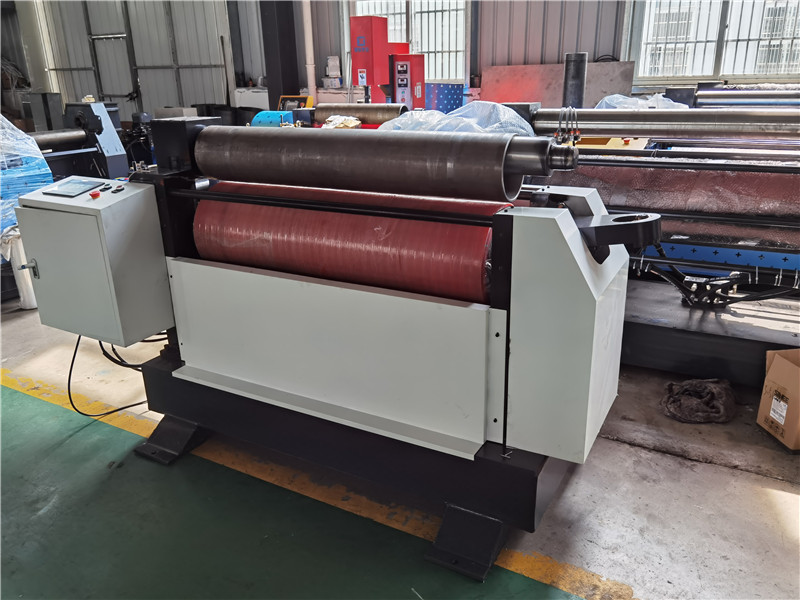

The two-roller plate rolling machine acts on the center symmetrical position of the piston, the two low rollers pass through the hydraulic oil of the hydraulic cylinder, and the two lower roller gears and the driving rotation cooperate through the main transmission gear of the main reducer to provide torque for plate rolling. There are two types of two-roller plate rolling machines: mechanical and hydraulic: mechanical two-roller plate rolling machines are divided into symmetrical machines and asymmetrical machines.

The difference between two-roll plate bending machine and four-roll plate bending machine

The function of the plate rolling machine is that it can roll the plate with thickness into a cylindrical shape, that is, according to the specified yield limit, the plate in the cooling state is used to roll out the plate with the maximum thickness and width of the minimum diameter of the reel. talent. Under normal circumstances, the capacity of cold rolling is about half of that of hot rolling. However, the ability of cold rolling of plate rolling machines has been continuously developed recently.

The two-roller rolling machine has only two rollers, the upper roller is made of steel, and the lower roller is an elastic roller, which can also be used for straight motion. When the plate rolling machine starts to work, first the lower roller starts to make a rotating motion, which promotes the sheet material and the upper roller to press the plate into the elastic layer of the lower roller under the action of the pressure of the movement, so that the lower roller is elastically deformed. However, the volume of the lower roller has not changed when the change occurs, so the pressure is transmitted to all sides, resulting in a strong and continuous back pressure, which makes the sheet material and the rigid roll closely adhere to each other, and finally enables the sheet to be rolled. Make a barrel. The depth of the upper roller under the pressure of the lower roller, that is, the amount of deformation of the elastic layer, is the primary technological parameter that determines the formed bending radius. Through many different tests, it is concluded that the larger the reduction, the smaller the bending radius of the sheet; but when the reduction reaches a certain value, the bending radius tends to be stable, and has almost nothing to do with the reduction. This is an important feature of the two-roll rolling machine process.

The position of the upper roller of the four-roller plate bending machine is fixed, and the lower roller moves straight up to clamp the steel plate. The rollers on both sides move toward the upper rollers in a straight line or in an arc to adjust the radius of curvature of the roll. The four-roller and two-roller rolling machines have different rolling motions, but the working principles are the same. However, the straight edge and roundness of the pre-bending of the four-roll plate rolling machine are better than those of the two-roller.