The characteristics of electro-hydraulic servo CNC press brake bending machine and its use process

The mold of the electro-hydraulic servo CNC press brake bending machine includes a bracket, a worktable and a clamping plate. When in use, the coil is energized by the wire, and after the electricity is energized, the pressure plate is gravitationalized, so as to realize the clamping of the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressing plate can be made into various workpiece requirements, and the workpiece with side walls can be processed, and the operation is also very simple. So what characteristics does it have when it is used, and what are the processes when it is used?

Features of electro-hydraulic servo CNC press brake bending machine:

- The hydraulic convex automatic compensation system is adopted to solve the influence of the deformation of the slider during the bending process on the quality of the workpiece. The amount of compensation is adjusted automatically by the numerical control system from the electro-hydraulic servo numerical control bending, which is convenient.

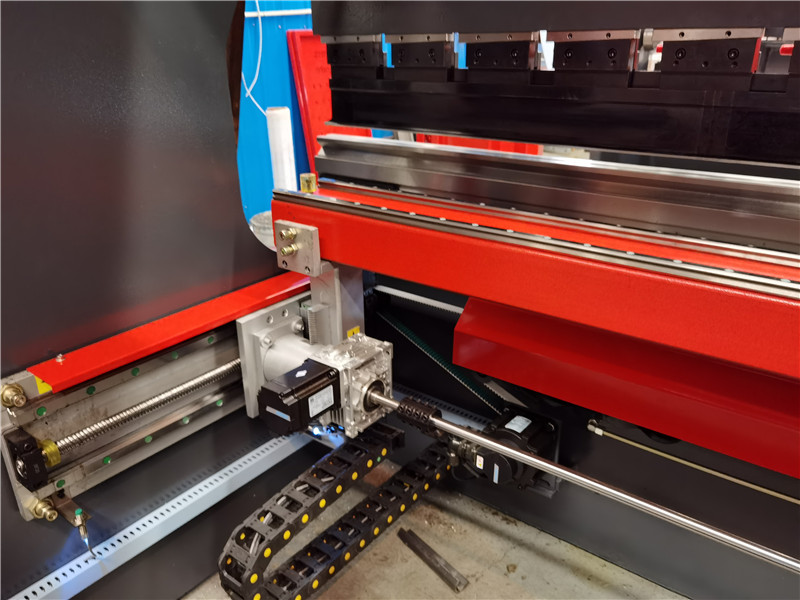

- It adopts a full-featured back gauge mechanism, and can choose to control multiple back gauge shafts. Functional parts in the back gauge. Such as guide rails, lead screws, bearings, etc. are all imported originals to ensure the accuracy of the back gauge.

- The fuselage adopts an integral welded structure, which is convenient for transportation and processing, and can ensure the overall accuracy of the machine tool.

- The fuselage, slider and other important components are analyzed by ANSYS finite element analysis software to ensure the reliability of the machine tool.

- The hydraulic system adopts the integrated control system imported from Germany, which reduces the installation of pipelines, improves the working stability of the machine tool, and has a beautiful and simple appearance.

- The numerical control system adopts Dutch DELEM65W and Italian ESA, or Dutch Cyblec!

- There are C-type plates on both sides of the fuselage, and the high-precision grating ruler is installed on the C-type plate, so as to avoid the influence of the deformation of the fuselage on the bending accuracy during bending.

The use process of electro-hydraulic servo press brake bending machine:

- The first is to turn on the power, turn on the switch on the control panel, and then start the oil pump, so that you can hear the rotation of the oil pump (the machine does not move at this time).

- Stroke adjustment, the use must pay attention to the adjustment of the stroke, and must be tested before bending. When the upper die goes down to the bottom, there must be a gap of plate thickness. Otherwise, it will cause damage to the mold machine. The adjustment of the stroke is also electric quick adjustment.

- Bending notch selection, generally choose a notch with a width of 8 times the thickness of the plate. For bending 4mm sheet, you need to choose a notch of about 32.

- The rear gauge adjustment generally has electric quick adjustment and manual fine adjustment, the method is the same as that of the shearing machine.

- Step on the foot switch to start bending. The mold of the CNC press brake bending machineis different from the shearing machine.

Well, the above is all the content that Xiaobian has shared with you. I hope it can help you after reading it.

Electro-hydraulic Servo CNC Bending Electro-hydraulic Servo CNC Bending Electro-hydraulic Servo CNC Bending Electro-hydraulic Servo CNC press brake bending machine