The advantages of flexible sheet metal panel box folding machine bending centers

The flexible bending center is a new generation of fully automatic multilateral sheet metal panel box folding machine bending centers, which is a new product for sheet metal bending to enter fully automated production. The flexible bending center does not require a mold for bending, and can bend complex shapes such as right angles, non right angles, arcs, up and down combinations. With one positioning, it can complete multilateral bending and is applied in the metal forming field of different industries and workpieces. Currently, the flexible bending center is gradually replacing CNC bending machines.

The advantages of flexible sheet metal panel box folding machine bending centers are reflected

Compared to CNC bending machines, flexible sheet metal panel box folding machine bending centers have the following advantages

- Fast bending speed

The advantage of a flexible bending center is its fast bending speed. Due to the manual adjustment of direction and bending required by the CNC bending machine, a large amount of manual labor is wasted. The bending speed of the flexible bending center is three times that of the CNC bending machine, greatly reducing the cycle time of multilateral and multi-channel bending, reaching 0.5 s/time. Full servo control can control the product accuracy within 3 seconds, greatly saving labor.

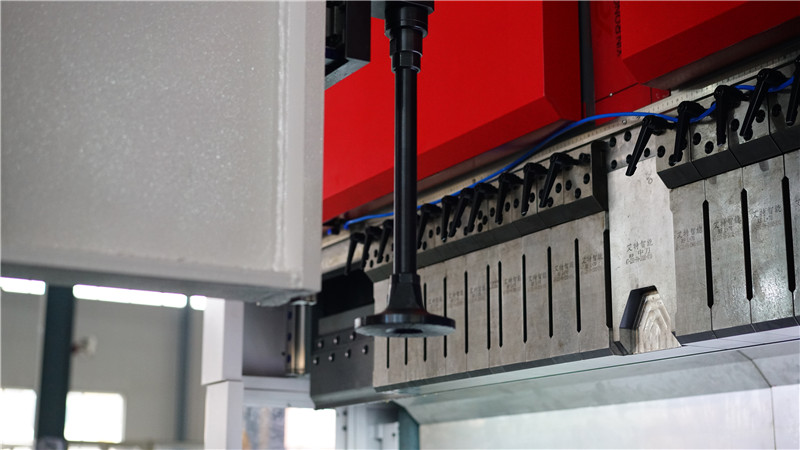

- No need to bend the mold

The flexible bending center adopts a universal bending mold and achieves various shapes of bending through multi axis concurrent linkage full servo control. However, the traditional CNC bending machine needs the first mock examination for each bending shape, and the cost is high.

- High degree of automation

The flexible bending center reserves rich interfaces for convenient docking with the upstream and downstream production lines of sheet metal. It can be docked with a robotic arm to achieve automatic integrated loading and unloading, achieving full automation.

- High safety factor

CNC bending machine: It requires manual feeding of bent parts into the bending machine for bending, which poses certain safety risks.

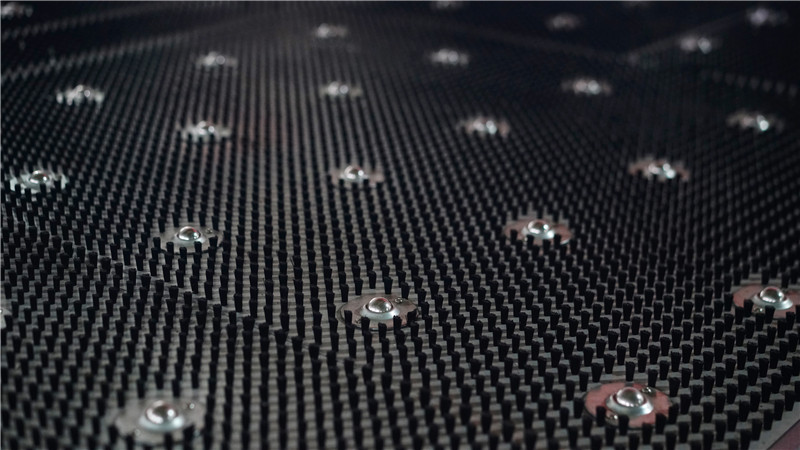

Flexible bending center: The bent workpiece is automatically pushed into the flexible bending center through the suction cup, and after the bending is completed, it is automatically pushed back through the suction cup. The entire process reduces manual intervention, and the safety performance of the flexible bending center is higher.