The advantages of electro-hydraulic servo synchronous cnc press brake cnc bending machine

Electro-hydraulic servo synchronous cnc press brake cnc bending machine is suitable for large-scale steel structure parts, iron towers, street light poles, high light poles, automobile beams, automobile cargo boxes and other related industries. Its essence is a CNC bending die for bending the thin plate. The die is composed of a bracket, a worktable and a clamping plate. By energizing the coil to generate a gravitational force on the pressure plate, the clamping of the thin plate between the pressure plate and the base is completed. Because the electromagnetic force clamping method is adopted, the pressing plate is made according to the specific workpiece requirements, the operation is simple, and the workpiece with the side wall can be processed.

The electro-hydraulic servo synchronous cnc press brake cnc bending machine is developed according to the principle of heating, softening, melting and welding of plastic plates, and it is suitable for the bending of all thermoplastic materials. The bending machine mold has the following characteristics: direct bending, no need for splicing, no need for grooving, no need for welding rod, its corner appearance is beautiful and watertight, and the processing speed is fast, the corner treatment surface is beautiful, and the strength is high. The manual welding is transformed into a fully automatic machine operation, which improves the quality, improves the labor efficiency, reduces the labor cost, and greatly shortens the production cycle of the product.

The advantages of electro-hydraulic servo synchronous cnc press brake cnc bending machine are:

- Direct angle programming, with angle compensation function.

- The real-time detection feedback correction of the grating ruler, the full closed-loop control, the positioning accuracy of the back gauge and the slider dead gauge is ±0.02mm.

- The upper die adopts a quick clamping device, and the lower die adopts a wedge deformation compensation mechanism.

- With multi-step programming function, it can realize multi-automatic operation, complete one-time processing of multi-step parts, and improve production efficiency.

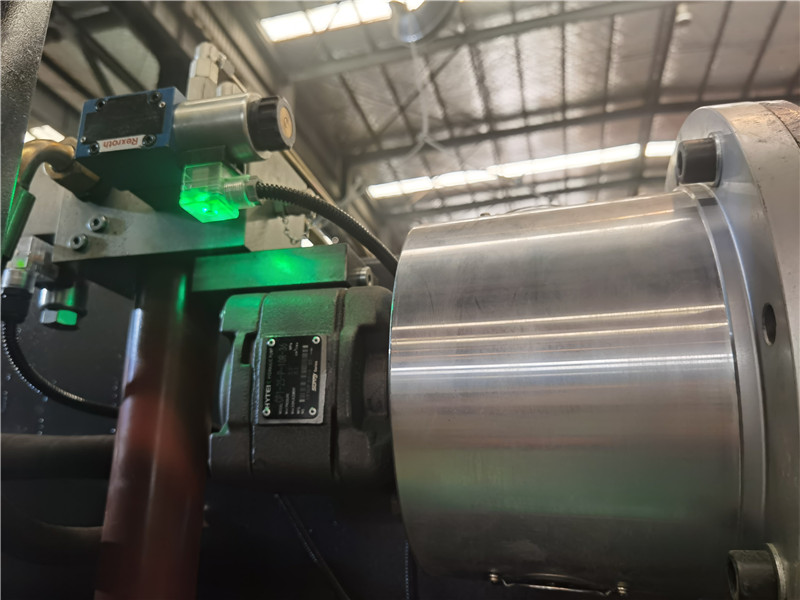

- According to user needs, the imported hydraulic system with stable performance and compact structure can be selected, and the back gauge can be driven by ball screw and synchronous belt.

Share the safety operation rules of the bending machine

Bending machine safety operation rules

- Strictly abide by the safety operation regulations of machine tool workers, and wear labor protection equipment according to the regulations.

- Before starting, it is necessary to seriously check whether the motor, switch, circuit and grounding are normal and firm, and check that the operating parts and buttons of the equipment are in the correct position.

- Check the coincidence and firmness of the upper and lower molds; check whether each positioning device meets the requirements of being processed.

- When the upper slide plate and each positioning axis are not at the origin, run the back-to-origin program.

- After the equipment is started, it should run idly for 1-2 minutes, and the upper skateboard will move 2-3 times in full stroke. If any abnormal sound or fault is found, the car should be parked immediately, the fault should be eliminated, and it can work only after everything is normal.

- When working, one person should be under the same command, so that the operating staff and the feeding and pressing staff should cooperate closely and closely to ensure that the cooperating staff are in a safe position before they can send the bending signal.

- When the sheet is bent, it must be compacted to prevent the sheet from lifting and hurting people during bending.

- The power supply must be cut off when the plate material is pressed, and the operation must be stopped.

- When changing the opening of the variable die, no material is allowed to come into contact with the die.

- When the machine tool is working, no one is allowed to stand behind the machine tool.

- It is strictly forbidden to fold the sheet at one end alone.

- If the workpiece or mold is found to be incorrect during operation, it should be parked for correction. It is strictly forbidden to correct by hand to prevent hand injury.

- It is forbidden to fold ultra-thick iron plates or quenched steel plates, high-grade alloy steels, square steels and plates that exceed the performance of the plate bending machine, so as not to damage the machine tool.

- Always check the coincidence of the upper and lower molds; whether the indication of the pressure gauge conforms to the regulations.

- Immediately shut down when an abnormality occurs, check the cause and eliminate it in time.

- Before shutting down, place a wooden block on the lower die under the oil cylinders on both sides and lower the upper sliding plate to the wooden block.

- Exit the control system program first, and then cut off the power supply.