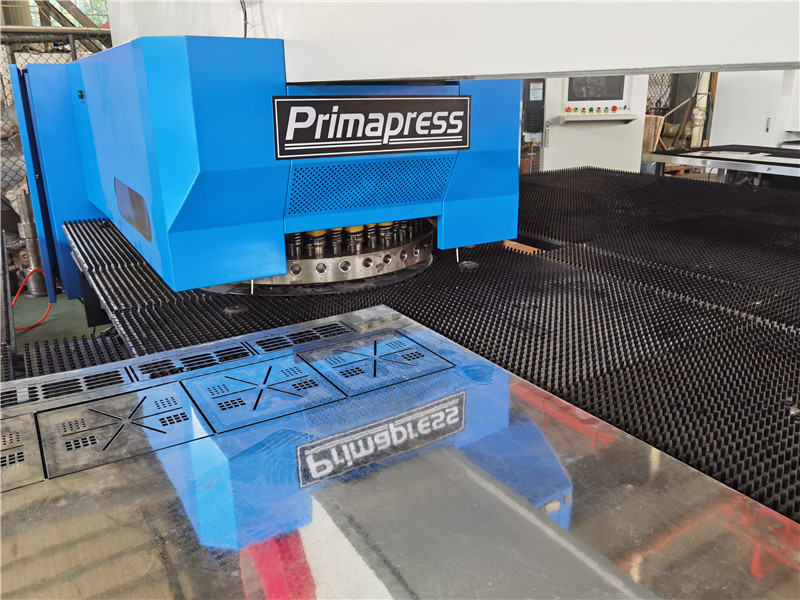

System structure and advantages and disadvantages of CNC turret punch press machine

In such a rapid economic development and the growth of all aspects of life, CNC turret punching machines have high productivity and high machining accuracy, so they are well received and favored by many consumers. So do you know the system composition of CNC turret punching machines? ? What are the advantages and disadvantages? Let’s take a closer look at the “system structure and pros and cons of CNC turret punch press”.

【System introduction of CNC turret punch】

The servo system is the link between the numerical control device and the numerical control punch, and is an important part of the numerical control system. The performance of the servo system largely determines the performance of the CNC turret punch. For example, important indicators such as moving speed, tracking accuracy, and positioning accuracy of CNC turret punching machines all depend on the dynamic performance of the servo system. Therefore, research and development of high-performance servo system has always been one of the key technologies of modern CNC turret punching machines.

CNC turret punch servo system is an automatic control system that controls the position and speed of the moving parts of the machine tool, also known as follow-up system, drag system or servo mechanism. In CNC machine tools, the servo system receives the feed generated by the computer interpolation software. The pulse or feed displacement is transformed and amplified into the displacement of the moving part. The servo system can be divided into position servo (the position of the table and the position and starting angle of the main shaft) and speed servo (the speed of the rotation of the table motor).

The composition and working principle of the servo system

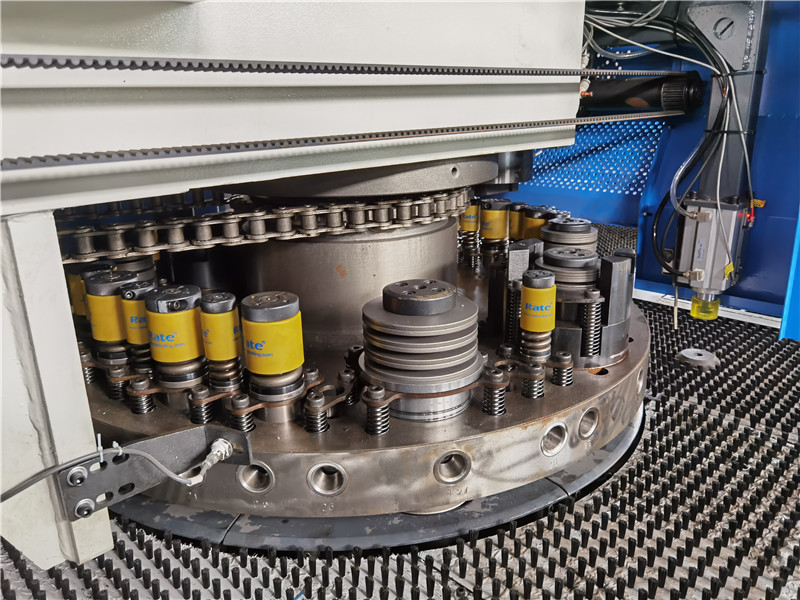

The CNC turret punch servo system consists of a speed loop and a position loop. As shown in the figure, this is a double closed-loop system. The inner loop is the speed loop and the outer loop is the position loop. Speed control is an important part of the servo system, and the speed loop consists of a speed control unit, a servo motor and a speed detection device. The speed control unit is used to control the speed of the motor and is the core of the speed control system. It is an independent unit, composed of speed regulator, current regulator and power drive amplifier.

The detection devices used for speed feedback in the speed loop are tachogenerators, pulse encoders, etc. The position loop is composed of the position control module, speed control unit, position detection and feedback control in the CNC device. The position control is mainly to control the motion coordinate axis of the machine tool. The coordinate axis control is the required position control. It not only has strict requirements on the control of the movement speed and position accuracy of a single uranium, but also requires that each moving uranium has a Good dynamic coordination can ensure processing efficiency, processing accuracy and surface roughness.

【Analysis of the advantages and disadvantages of CNC turret punch press】

CNC turret punching machines have many advantages. They are: strong adaptability to parts and can process parts surfaces of complex shapes; high productivity; high machining accuracy and stable machining quality; shortened production preparation time, facilitated modern management; reduced labor for workers strength.

(1) Compared with ordinary machine tools, CNC turret punching machines can improve production efficiency by 3 to 5 times, and use CNC machining center machine tools to achieve productivity of 5-10 times;

(2) CNC turret punching machine can obtain higher machining accuracy than the machine tool itself;

(3) Complex shape parts can be processed without special fixtures;

(4) One machine can be used for multiple purposes, reducing labor intensity and saving plant area:

(5) It is conducive to the development of computer control and management, and is conducive to the development of comprehensive automation of machining;

(6) The initial investment and maintenance technology of CNC turret punch presses are relatively high, and the quality of management and operators is also high.

The CNC turret punching machine better solves the problems of complex shape, high precision, small production batch, short production cycle and frequent product replacement. It is a flexible and high-efficiency automatic machine tool. CAI (DNC), flexible manufacturing system (FMS), computer integrated manufacturing system (CIMS, computer inIegrated manufacttem) and other important devices for flexible processing and the basis of the temperament manufacturing system.

CNC turret punching also has disadvantages. They are: expensive and large initial investment in equipment; high technical requirements for users and maintenance personnel due to the integration of mechanical, electrical, hydraulic and computer technologies; manual programming workload when processing complex-shaped parts.

The above introduction of “System Introduction of CNC turret punching Machine” and “Analysis of the Advantages and Disadvantages of CNC turret punching Machine” hopes to help you understand the “system structure and description of advantages and disadvantages of CNC turret punching machine”.