Summarize the development history of automatic pipe bending machine

The pipe bender is a machine with a very wide range of applications. The pipe bender is a machine with a very wide range of applications, ranging from a small part of a refrigerator to the bending of open pipes. With the advancement of technology in various industries, new requirements have been put forward for the precision and composite processing technology of pipe bending machines. The working principle of the pipe bending machine is to apply a bending moment through a reasonable fulcrum and a force point to make the steel pipe plastically deform, so as to achieve the purpose of cold bending of the steel pipe. The frame is in a floating state, the steel pipe is introduced into the lower mold from the back of the bending machine through the clamp and the upper mold by means of a spreader, and the inner tube is loaded into the steel pipe and placed in the center of the upper mold. So that the steel pipe can avoid abnormal deformation during the bending process.

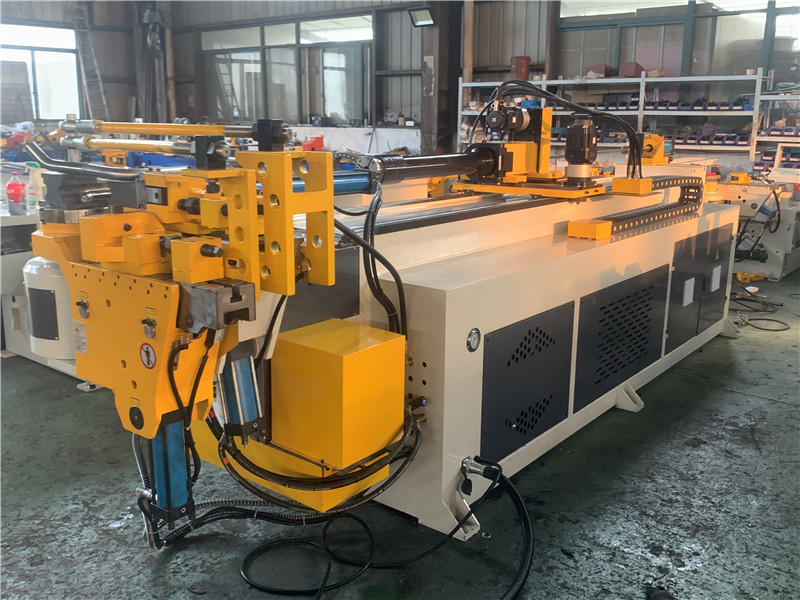

In the development of the pipe bending machine, the power source of the pipe bending machine has been continuously improved and improved. In the early days of manual bending of pipe materials, the main power source was the labor of a single or multiple operators, and the processed products were generally It is a tube of small pipe fittings. This processing method has low production efficiency, insufficient precision and limited tube shape. With the development of modern technology and the improvement of industrial level, some high-performance pipe bending machines such as CNC numerical control pipe bending machine, three-dimensional hydraulic pipe bending machine and so on have been developed. The main driving methods of these high-level pipe bending machines are generally There are three types: motor drive, hydraulic drive, and motor-hydraulic hybrid drive.

- Motor drive

In today’s modern industry, the power source of most mechanisms and devices is driven by motors, which provide power for the basic movements of the entire device. The source power is provided by the motor, and there are many ways in the power transmission process. For example, the gear, rack, cam, connecting rod and other mechanisms can be driven by the motor, and the pipe bending machine that meets the requirements can be designed according to the situation.

- Hydraulic drive

With the continuous development of industrial technology, hydraulic transmission technology is one of the fastest developing technologies in mechanical equipment, especially in recent years, it has entered a new stage of development. Hydraulic transmission and control system is widely used in all walks of life due to its advantages of high transmission power, high control precision, fast response speed and easy realization of integrated control of motor and liquid. The hydraulic pipe bending machine powered by hydraulic pressure is a new type of pipe bending mechanism. It has the advantages of reasonable structure, convenient operation, safe use, fast loading and unloading, and one machine for multiple purposes.

- Motor-hydraulic hybrid drive

Although the hydraulic elbow has the advantages of high transmission power, high control precision and fast response speed, it also has some shortcomings, such as: the production efficiency is low due to too many movements of the operator; the machine loss is large and the service life is shortened; More operators are required, labor costs are high, and product costs are high. Therefore, in the further research, it is proposed to use the motor-hydraulic hybrid drive, which can reduce the production cost, improve the production efficiency and improve the machining accuracy by using the most reasonable driving method in the respective advantages of the motor and the hydraulic pressure.