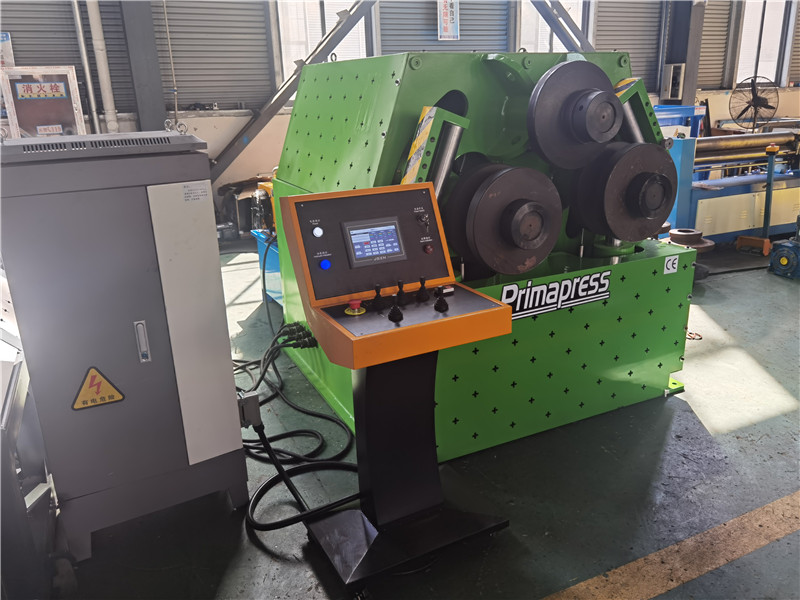

Structural performance description of Angle steel bar Profile Bending rolling Machine

1、 The main technical characteristics of the structural performance description of the profile bending machine This model is a three roll bending machine with arc downward adjustment. The bed is a steel plate structural part, which is subject to internal stress relief treatment. The transmission of the main roll is transmitted to the power through the hydraulic system through the hydraulic motor, gear, and sprocket for rotary movement. The two side rollers move in an arc around the central axis. The power transmitted by the hydraulic system through the hydraulic motor and gear rotates with the main roller at the same time. The idler is installed on the side roller to make the idler move in an arc with the side roller at the same time, so as to ensure the accuracy of rolled profiles. According to the requirements of the site and the profile, it can be installed vertically or horizontally. This model is fully driven by three rollers, which can pre bend the end of the profile. By adjusting the guide roller, the distortion generated in the asymmetric coiling process can be corrected. All actions are completed by the buttons on the electrical control cabinet. The displacement digital display has a display accuracy of 0.1mm. Different shapes can be rolled according to the shape of profile section. The biggest advantage of this type of equipment is good precision and high efficiency of rolling profiles.

2、 Structural performance description of Angle steel bar Profile Bending rolling Machine Technical parameters: 1 Equipment name and specification: W24S-16 material maximum bending section modulus 16cm material yield limit 250MPa angle steel external bending maximum section 708 minimum bending diameter 800mm minimum section 303 minimum bending diameter 550mm angle steel internal bending maximum section 708 minimum bending diameter 800mm minimum section 303 minimum bending diameter 550mm flat steel horizontal bending maximum section 14020 minimum bending diameter 400mm flat steel vertical bending maximum section 7516 minimum bending diameter 500mm Channel steel external bending Channel steel model 12 Minimum bending diameter 1000mm Channel steel internal bending Channel steel model 12 Minimum bending diameter 1000mm Circular pipe bending maximum section 5030mm Minimum bending diameter 750 Profile steel external bending maximum section 12 Minimum bending diameter 600mm Profile steel internal bending maximum section 12 Minimum bending diameter 600mm Working speed 2.5m/min Motor power 5.5kw Motor speed 1500ypm

3、 The machine is mainly composed of bed, side roll, idler, transmission, electrical, hydraulic system and mold. This machine is an arc three roll profile bending machine produced by introducing Swedish technology, which has the pre bending function of profiles. The three working rolls are the main driving rolls, which are realized through hydraulic motors and gears. The lifting of the two lower rolls is hydraulically driven. The two lower rolls can perform arc lifting movement around the fixed rotary center. The two sides of the working roll are equipped with idler and straightening guide roll devices, which is conducive to ensuring the quality of the rolling of asymmetric section (such as angle steel) profiles.

The structural performance of the profile bending machine shows that there are three movements of the idler straightening roll:

(1) Can do lifting movement;

(2) It can simultaneously perform arc lifting movement with the lower roll;

(3) It can rotate at the same time to ensure the forming quality of the profile in the rolling process. The lifting displacement of the two lower rolls is displayed by numbers, which is eye-catching and intuitive. The machine is equipped with an independent console, which is easy to operate. The machine bed is of welded steel plate structure and annealed to eliminate internal stress. The whole machine has enough strength and stiffness to meet the bending of profiles within the machine’s capacity. When replacing the mold, angle steel, flat steel, square steel, channel steel, I-beam, round steel, steel pipe and other profiles can be rolled. The machine is advanced in structure, reliable in operation, small in size and complete in functions. It is an advanced profile forming equipment at home and abroad. It is widely used in boiler, shipbuilding, hydropower, metal structure and other industries.