Some consideration points before purchase of CNC sheet metal electro-hydraulic bending machine

Performance characteristics of electro-hydraulic bending machine

1. The host is equipped with a special CNC system for shears.

2. The back gauge position is displayed in real time.

3, multi-step programming function, the back gauge automatically runs and continuously locates, realizes the automatic adjustment of the back gauge position.

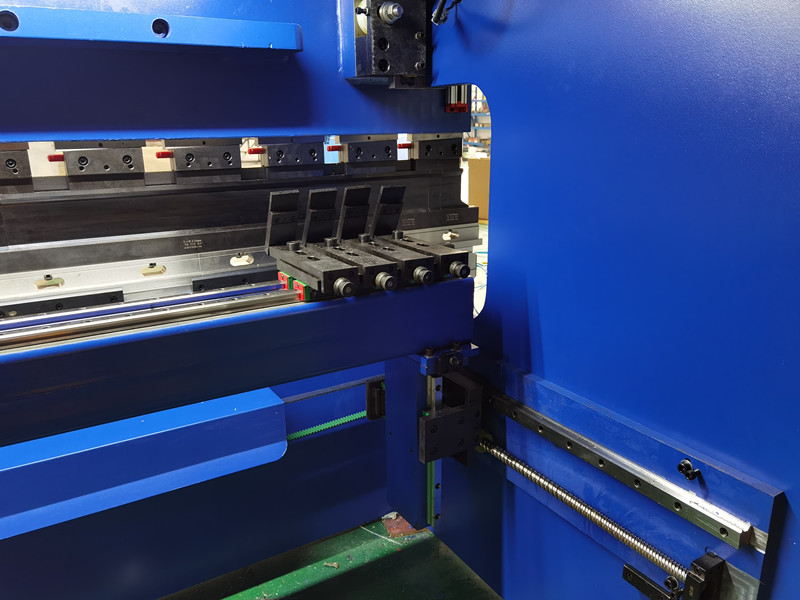

4. Shear counting function, real-time display of the number of shears, and memory of the gauge position, program and parameters after power failure.

5. Imported ball screws and linear guides are used to ensure positioning accuracy and higher machining accuracy.

6.jpg

How to choose an electro-hydraulic bending machine

1. The main difference between electro-hydraulic servo CNC bending machine and ordinary CNC bending machine is whether it has feedback closed loop and

whether it has electro-hydraulic bending machine compensation.

2. Calculate how many tons of shears need to be purchased according to the material and thickness of the metal sheet to be processed and bent;

Note: The tonnage here refers to the maximum pressure of the bending machine, not the electro-hydraulic servo CNC The weight of the bending machine;

3. Determine the blade face width, throat depth, and distance between the columns of the electro-hydraulic servo bending machine according to the

length of the stainless steel and other plates to be processed. After determining the tonnage and main parameters, you can start looking for a suitable manufacturer;

4. Manufacturers or brands of electro-hydraulic synchronous bending machines. Electro-hydraulic bending machines are more intelligent and fully automated.

The quality, price and after-sales service of different manufacturers are quite different; domestic brands are the top ten brands such as Yawei;

5. There are many additional functions that can be selected for the electro-hydraulic servo synchronous bending machine. This needs to be customized

according to the requirements of the workpiece, such as the number of axes, compensation type, laser test, safety protection (laser protection or light curtain protection), etc.