Similarities and differences between fiber laser cutting machine and water jet cutting machine

Both the laser and the water jet were machining tools that appeared in the late 60s. The techniques and methods used by the two are also completely different. There are many sheet metal factories who will wonder: should one choose between laser and water jet?

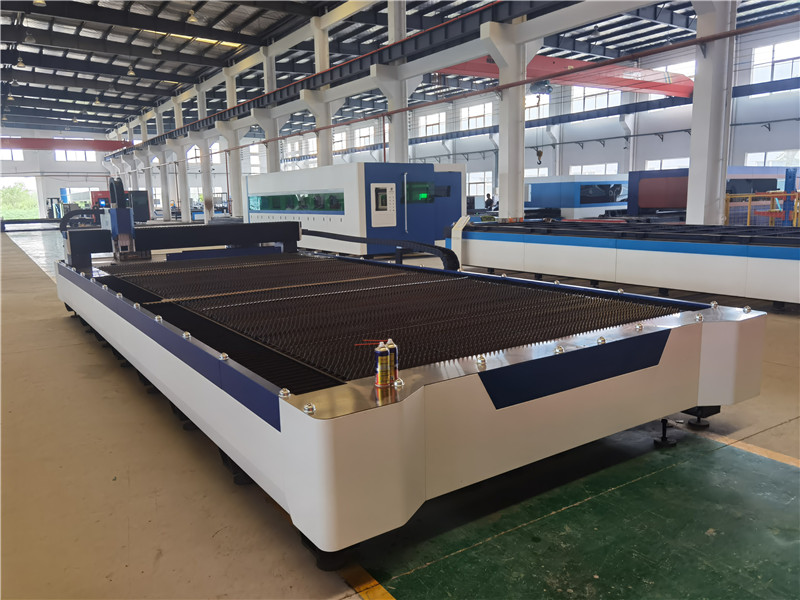

NO.1 Fiber Laser Cutting Machine

Fiber laser cutting machine was originally developed to drill holes on diamond dies. It uses laser radiation heating to cut the workpiece. This technology is unmatched in speed and precision. Therefore, it has been likened to a “Swiss Army Knife”.

Features

The cutting precision is high, and it can be used to process workpieces with complex shapes, and at the same time, it causes little waste;

Suitable for cutting thin materials, such as plastics, ceramics or metals with a thickness of less than 25mm;

Cuts can be made quickly from any direction.

At present, there are two kinds of fiber laser cutting machines, one is CO2 cutting (carbon dioxide cutting), and the other is fiber fiber laser cutting.

The difference between CO2 cutting and fiber laser cutting:

- Power

Fiber optic fiber laser cutting machine: With diode aurora system, it can efficiently transmit very high power without any attenuation.

CO2 fiber laser cutting machine: The power is difficult to increase, and the reflector it uses may burn out when the power is high.

Therefore, the available power of fiber laser cutting machine is much higher than that of CO2 fiber laser cutting machine.

- Cutting thickness

In many cases today, fiber lasers can cut as thick as CO2, but it is more efficient than CO2, using up to 70% less power and wearing less.

- Simplicity Many fiber laser manufacturers refer to the installation of fiber laser cutting machines as “plug and play”. For users who need this technology, fiber lasers offer high efficiency and quick cost recovery.

Fiber laser cutting has become a low-cost production mode due to its fast cutting speed, short time and high precision.

In addition, using manufacturing management software such as Lantek MES, which is compatible with more than 1,200 equipment on the market, there is no need to worry about equipment wear or tool replacement costs, and maintenance costs are not high. Therefore, it can help sheet metal factories save costs while improving production efficiency.

NO.2

water jet cutting machine

A more economical alternative to fiber laser cutting is water jet cutting, originally proposed by Norman Franz, a professor at the University of British Columbia in Canada, who discovered that water flow has a huge cutting force under high pressure.

Features:

It has a wider application range than fiber laser cutting, because it is cold cutting and can be applied to many kinds of materials.

It is a sustainable and eco-friendly cutting method for heat-sensitive materials.

It does not cause thermal damage to the workpiece and can be used in extremely demanding industries such as aviation, marine, automobile manufacturing, textile and shoemaking, ceramics, machining and other industries.

Not for cutting absorbent materials, such as wood, or materials that may corrode when exposed to moisture.

Another advantage of waterjet cutting is that it can use 3D nesting software because it can cut from any direction.

Surfaces can be cut when the water is sprayed from the nozzle with great force to a specified location on the material under high pressure; when cutting softer materials, only pure water is used; for harder materials, it is usually used Garnet sand, mix it with water, which is good for sheet metal cutting.

Depending on the thickness of the workpiece, the nozzle size varies, the smaller the nozzle, the thinner the cut material, and vice versa. But when cutting very thick and hard materials, it takes more time and therefore increases the cost.

While waterjet cutting is more economical, it is expensive to maintain because parts such as high pressure pumps, cutting heads, etc. wear out.

Epilogue

The two technologies, fiber laser cutting and water jet cutting, have a common advantage, that is, compared with other methods (plasma, oxy-fuel cutting), their cutting width is very small, so they can be used for small workpieces that other machines cannot cut.

To sum up, laser and water jet cutting methods are very different, but they are not one or the other, but complement each other. Sheet metal factories can be used complementary as needed. Once your factory has these two cutting machines, the competitive advantage will undoubtedly increase significantly. Because no matter in the type of cutting material, the thickness of the workpiece, or in the post-factory order management system, you.