Sheet metal CNC servo press brake bending robot advantages and using area

What are the advantages of choosing a CNC bending robot?

The most widely used in the sheet metal processing industry is to use a universal six-axis robot plus a CNC bending machine instead of manual to complete

the bending process. However, not every company is suitable for bending robots. You must truly understand in the process of communicating with customers.

Before making recommendations based on the actual situation of the customer, the following points are particularly important:

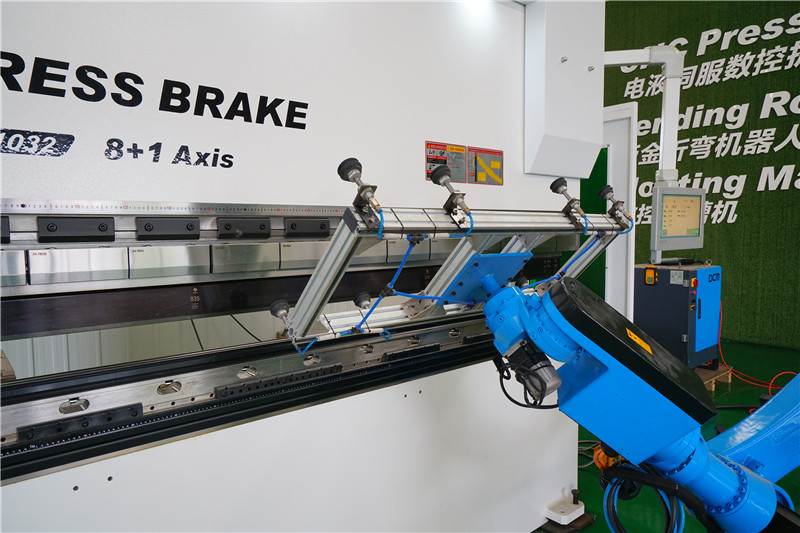

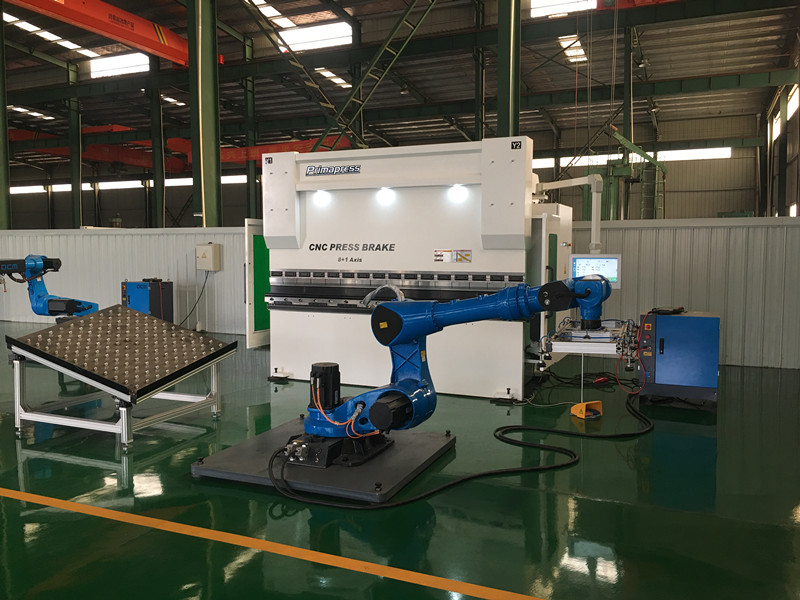

CNC bending robot

1. High productivity and high efficiency to shorten the order cycle: The robot solves the labor intensity and safety risk problems of manual operation,

and at the same time, the characteristic of 24 hours continuous and fatigue-free operation is unparalleled. At the same time, no holidays greatly shorten the order production cycle.

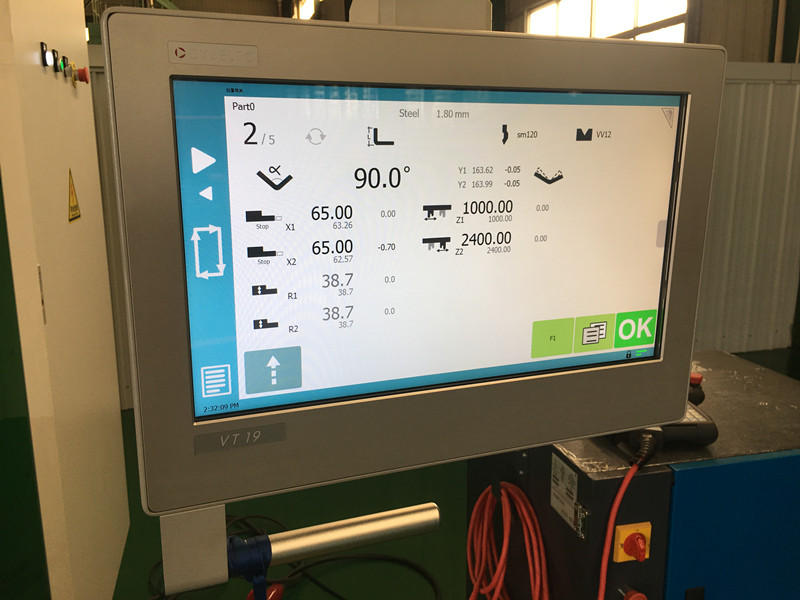

2. High flexibility and high stability: The robot is controlled by a computer system, and the product quality is consistent.

3. High quality consistency: ±0.05mm repeat positioning accuracy, 75,000+ hours mean time between failures.

Robots are unmanned operation, no working hours for bending, consistent product quality, more accurate than manual operation, robots replace labor,

safer and more reliable, and no holidays shorten the production cycle of orders.

In summary, CNC bending machine robots are suitable for companies that process large workpieces, large quantities, and few types of workpieces.

Not all companies are suitable for robotic bending.

In the 21st century, with the rapid development of industry, the employment costs of enterprises continue to increase, and management costs and

difficulties are gradually rising. As a result, many companies have begun to upgrade their production equipment, and the coverage of smart production is getting higher and higher.

CNC bending robot

The most widely used in the sheet metal processing industry is to use a universal six-axis robot instead of manual to complete the bending process,

but not every company is suitable for bending robots. In the process of communicating with customers, you must truly understand the actual situation of the customer.

Recommended, the following points are particularly important:

1. Workpiece weight: The robot is suitable for bending large work pieces; its biggest advantage is that it can work continuously 24 hours a day,

and the overall efficiency can be greatly improved under normal maintenance and trouble-free conditions. However, if manual bending is used, large workpieces

have high requirements on the physical strength of workers, and they cannot work continuously. If it is a small workpiece with a complicated bending procedure

and a small quantity, it is not recommended to use a robot. The efficiency of manual bending will be much higher than that of robot bending.

- Workpiece type: A robot is recommended to bend five to six workpieces. It is impossible for one robot to cover all the bending workpieces of the enterprise.

- It does not mean that the robot cannot be folded, and if it is fully covered, then the robot is debugged. The cost will be high.

3. Optional: If the workpiece is large or needs a large bending area for other reasons, a seventh axis should be installed after the robot is selected,

which can increase the range of motion of the robot and meet the bending needs. Also, if customers want to reduce manual intervention,

they can speed up the change of grippers, which can reduce the time for workers to change robot grippers.

In summary, CNC bending robots are suitable for companies that process large workpieces, large quantities, and few types of workpieces.

Not all companies are suitable for robot bending.