Relationship between cutting speed of Metal fiber Laser Cutting machine and material cutting

- The proper increase of the speed of the Metal fiber Laser Cuttingmachine can not only improve the quality of the kerf, but also reduce the deformation of the kerf because the kerf is narrow and flat. 2. If the cutting speed is too fast, the cutting line energy will be lower than the

- The proper increase of the speed of the Metal fiber Laser Cuttingmachine can not only improve the quality of the kerf, but also reduce the deformation of the kerf because the kerf is narrow and flat.

- However, if the cutting speed is too fast, the cutting line energy will be lower than the required value. If the molten material cannot be quickly blown off by blowing during the cutting, it will show a large amount of drag, affecting the integrity of the incision, and even the need for secondary treatment may occur.

- If the speed of the Metal fiber Laser Cuttingmachine is too low, the cutting place will be exposed to the high temperature of the laser for a long time, which will not only cause the cutting joint to become larger, but also may affect the beauty of the cutting joint due to too much heat conduction, and the slag will appear on the back of the metal.

- When the speed is extremely low, the notch melts too much, the cutting seam is wider, and even causes the arc to extinguish, which makes it impossible to cut. Therefore, the cutting speed will affect the cutting quality, not only from the cutting speed. I hope you should be careful when operating the metal Metal fiber Laser Cuttingmachine.

How to ensure the cutting speed and accuracy of the Metal fiber Laser Cutting machine?

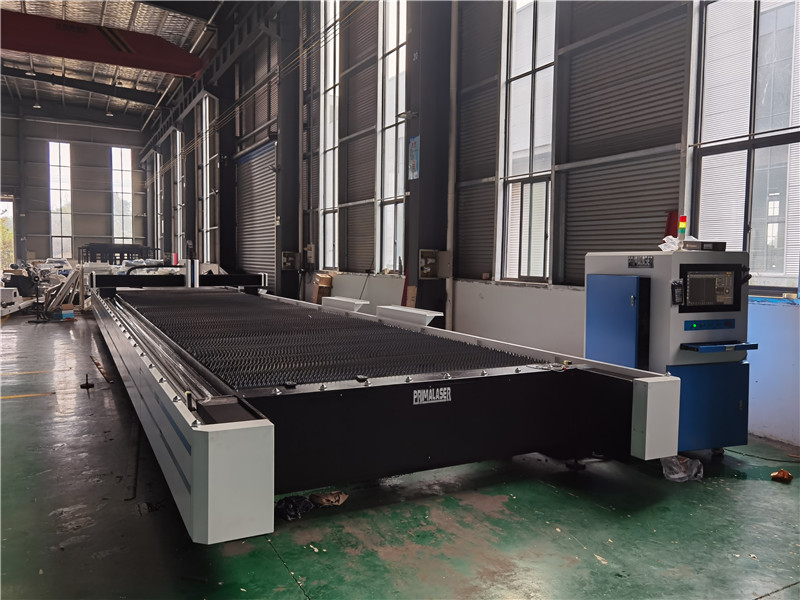

How to debug the Metal fiber Laser Cutting machine to make it cut faster and better? In fact, the Metal fiber Laser Cutting machine is like a car. It needs to be tested and debugged before leaving the factory, and it needs to be maintained during use, so as to keep the equipment in good operation

How to debug the Metal fiber Laser Cutting machine to make it cut faster and better? In fact, the Metal fiber Laser Cutting machine is like a car. It needs to be tested and debugged before leaving the factory and maintained during use to keep the equipment in a good operating state. There are many components of the Metal fiber Laser Cutting machine and the maintenance period of some parts is relatively short. For example, the protection lenses should be updated frequently according to the cutting frequency and working time.

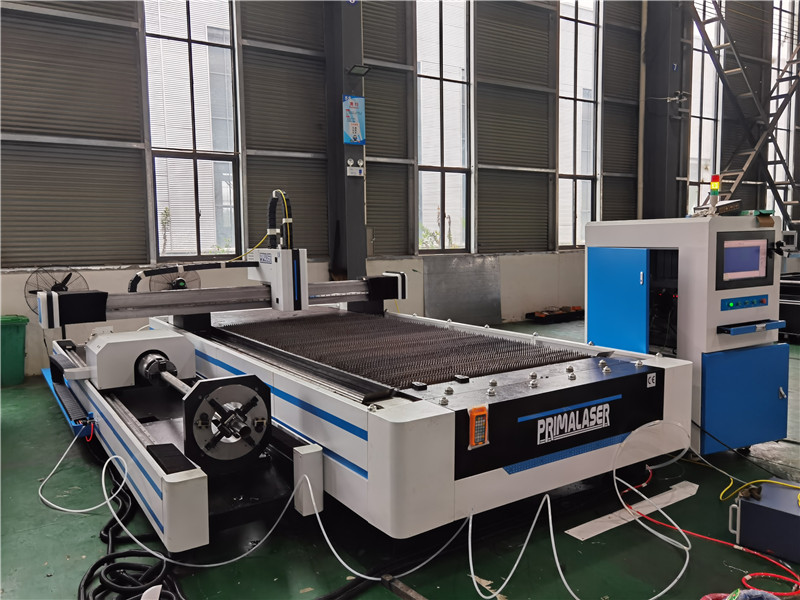

1、 Adjust the machine assembly to improve the cutting effect of the machine.

- Guide rail: when installing the guide rail, it must be parallel. If the guide rail is not parallel, the machine will run with resistance, and the workpiece cut will have sawtooth trimming. Therefore, the guide rail of Y axis must be parallel.

- Beam and coupling: During the installation of the beam and coupling of the machine, if the screw thread is not locked, or the lock is oblique or loose, the cutting effect of the Metal fiber Laser Cuttingmachine will be affected. Therefore, the installation quality and accuracy of parts must be guaranteed.

2、 Adjust the laser machine parameters and improve the cutting speed of the machine.

During the cutting process, the machine parameters need to be adjusted step by step. Generally, if the machine parameters are not adjusted properly, the cutting speed and effect will be affected to some extent. When leaving the factory, each laser cutter sets and saves the parameters according to the power, cutting material and thickness. Later, it can be adjusted according to the user’s needs. In general, the following points should be noted when setting parameters:

- Initial speed: As the name implies, this setting is the starting speed of the machine. The initial speed is not as fast as possible. In fact, if the speed is too fast, the machine may shake severely at the beginning.

- Acceleration: The acceleration is a process of acceleration from the initial speed to the normal cutting when the machine is in production. Similarly, there will be a process of deceleration when the machine is ready to finish cutting. If the acceleration is too low, the cutting speed of the machine will slow down.

3、 Metal fiber Laser Cutting machine precision debugging method.

- When the light spot of the focus laser is adjusted to the minimum, the initial effect is established by spot shooting, and the focus position is determined by the size of the light spot effect. As long as we recognize that the light spot of the laser is at the minimum, then this position is the best processing focus, so as to start processing.

- In the first part of the Metal fiber Laser Cuttingmachine debugging, we can use some test paper and workpiece waste to spot judge the accuracy of the focus position. Move the height of the upper and lower laser heads, and the laser spot size will change in different sizes when it is pointed. Adjust different positions for many times, and find the smallest spot position to determine the best position of the focus and laser head.