Purchase process of primapress 200T/3200mm electric hydraulic press brake

First:Meet customers briefly introduce the electric hydraulic press brake bending machine

In 2021, on December 13th, I sent the first email to the customer, first briefly introduced our company as a production enterprise, then briefly asked the customer’s needs, established a basic contact with the customer, and then understood the customer’s needs and Regarding the thickness and length of the processed plate, we recommended the quotation of DA53T of 160T/3200 and the laser cutting machine integrated with plate and tube, and suggested the preliminary quotation and contact.

Second: Help customers understand all the mechanical details, and answer customer technical questions

Then, the customer responded to us by email, and communicated with the customer to understand that the customer is not an end user, they are also a trading company, they are to let their customers understand the purchase of machinery, and then give the customer a detailed introduction to the functions of our DA53T and some according to the customer’s plate length and width, here we recommend the 200T/3200 electric hydraulic press brake bending machine he needs, and then make a quotation to the customer.

According to the customer’s needs, we also let him know the price to their port, as well as the basic cost of shipping, try to meet all the needs of the customer and help him solve the problem

Third:Solve the current doubts of customers

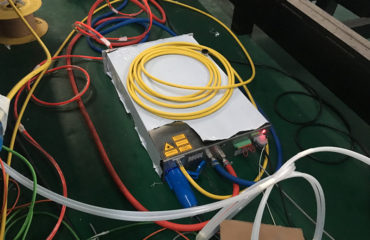

The customer first raised questions about our motors, backgauges, and linear guides. I provided photos and various photos of Siemens motors. The customer had questions about the thickness of his 4MM, and the customer provided him with bending products. I told him that it was Yes, and there is no problem with the thickness, and give him the drawings of the upper and lower molds to facilitate his confirmation. The customer finally gave me the company information and made a complete PI.

The customer also compared the E21, and asked the price of the general machine. At the same time, I told him that if he bought the general machine NC, he could try the TP10S system of our button shaft. At the same time, I also talked with the customer about many other mechanical equipment, such as 4KW 3015 single-platform laser cutting machine and fully enclosed switching table laser cutting machine provide customers with quotations and technical parameters and configurations.

At the same time, I sent photos and videos of some systems of DA53T to the customer. The customer was very satisfied after watching it, and then asked some questions. The first customer asked about the delivery date of the product, and the second asked about the mold of the product.

Regarding the mold part of the electric hydraulic press brake bending machine, I sent the photos of the molds that we usually use in the electro-hydraulic electric hydraulic press brake bending machine, and designed the mold for the customer according to the thickness and angle of the bending plate, and the customer was very satisfied.

And inform customers that our molds are free standard segmentation.

Forth: The customer pays and is in production

Then all the questions of the customer were solved. The voltage and color required by the machine were confirmed with the customer here. The production order was placed here, and the customer paid the deposit in advance.