Description

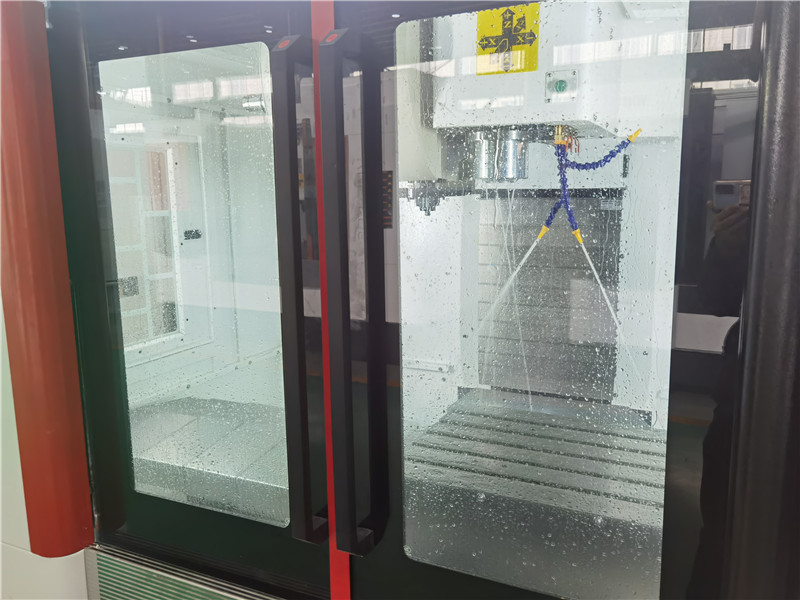

Taiwan quality VMC Vertical cnc milling machine 50S 60S cnc vertical machining center machine

VMC-60S Optical and mechanical characteristics:

- The machine bed is made of HT300 high-grade cast iron;

- Germany INA line rail is adopted, and the width of X/Y/Z three-axis rail is 45/45/45mm;

- The X/Y/Z three-axis guide rail spans are 340/745/440mm respectively;

- The three shafts all use C3 high precision lead screws with a diameter of 40 and a pitch of 12. The three shafts use five FAG original bearings (3062), three at the motor end and two at the tail end, and are pre tensioned;

- X-axis and Z-axis adopt 6-slider mode to ensure cutting rigidity;

- BT40-150 high rigid main shaft is used for circular spraying;

7.The lead screw guide rail lubrication system adopts fully automatic intermittent thin oil lubrication; All oil pipes are made of pure copper;

3、 Main technical parameters

| project | Specifications | unit | VMC-60S |

| trip | X/Y/Z axis | mm | 1100/600/600 |

| Distance from spindle nose to workbench | mm | 120-720 | |

| Distance from spindle center to column guide rail surface | mm | 650 | |

| Guide rail form | Linear Guide | ||

| worktable | Table size | mm | 1200×600 |

| Maximum load of workbench | kg | 800 | |

| T-groove | No/mm | 5-18×100 | |

| principal axis | Spindle specifications | mm | BT40 |

| Spindle speed | rpm | 8000 | |

| Spindle transmission mode | Belt type | ||

| Tool magazine device | Tool magazine form/tool change time (tool setting) | Disc type BT40/ 1.5S | |

| Magazine capacit | tools | 24 | |

| Maximum tool diameter (temporary tool) | mm | 78 | |

| Maximum tool diameter (no temporary tool) | mm | 120 | |

| Maximum tool length | mm | 300 | |

| Maximum tool weight | kg | 8 | |

| Movement rate | X、Y、Z axis Rapid feed | m/min | 36 / 36 / 24 |

| Cutting feed rate | m/min | 0.005~10 | |

| electric motor | Spindle power/torque | kW,Nm | βiI 12/10000,11/15,52/95 |

| X-axis servo motor | kW,Nm | βiS 22/3000 ,3,20 | |

| Y-axis servo motor | kW,Nm | βiS 22/3000 ,3,20 | |

| Z-axis servo motor | kW,Nm | βiS 22/3000 ,3,20 | |

| Precision (VDI German standard) | Positioning accuracy (VDI full stroke) | mm | 0.010/0.010/0.010 |

| Repeated positioning accuracy (VDI full stroke) | mm | 0.008/0.008/0.008 | |

| Power demand | Power requirements | kva | 20 |

| Air source requirements | kg/cm | 6-8 | |

| Machine tool dimensions | L * W * H | mm | 3100×2550×2800 |

| weight | t | 7 |

3、 Main technical parameters

| project | Specifications | unit | VMC-60S |

| trip | X/Y/Z axis | mm | 1100/600/600 |

| Distance from spindle nose to workbench | mm | 120-720 | |

| Distance from spindle center to column guide rail surface | mm | 650 | |

| Guide rail form | Linear Guide | ||

| worktable | Table size | mm | 1200×600 |

| Maximum load of workbench | kg | 800 | |

| T-groove | No/mm | 5-18×100 | |

| principal axis | Spindle specifications | mm | BT40 |

| Spindle speed | rpm | 8000 | |

| Spindle transmission mode | Belt type | ||

| Tool magazine device | Tool magazine form/tool change time (tool setting) | Disc type BT40/ 1.5S | |

| Magazine capacit | tools | 24 | |

| Maximum tool diameter (temporary tool) | mm | 78 | |

| Maximum tool diameter (no temporary tool) | mm | 120 | |

| Maximum tool length | mm | 300 | |

| Maximum tool weight | kg | 8 | |

| Movement rate | X、Y、Z axis Rapid feed | m/min | 36 / 36 / 24 |

| Cutting feed rate | m/min | 0.005~10 | |

| electric motor | Spindle power/torque | kW,Nm | βiI 12/10000,11/15,52/95 |

| X-axis servo motor | kW,Nm | βiS 22/3000 ,3,20 | |

| Y-axis servo motor | kW,Nm | βiS 22/3000 ,3,20 | |

| Z-axis servo motor | kW,Nm | βiS 22/3000 ,3,20 | |

| Precision (VDI German standard) | Positioning accuracy (VDI full stroke) | mm | 0.010/0.010/0.010 |

| Repeated positioning accuracy (VDI full stroke) | mm | 0.008/0.008/0.008 | |

| Power demand | Power requirements | kva | 20 |

| Air source requirements | kg/cm | 6-8 | |

| Machine tool dimensions | L * W * H | mm | 3100×2550×2800 |

| weight | t | 7 |

If any supplier fails to supply, it will be replaced by a brand of no less than the same quality.

4、 Main accessories

| Serial No | name | number | Manufacturer | Specification and model |

| 1 | system | 1set | Fanuc, Japan | FANUC 0i-MF;10.4″Color LCD display |

| 2 | Spindle servo motor | 1set | Fanuc, Japan | βiIP30/8000 |

| 3 | X、Y、Z servo motor | 1 set for each | Fanuc, Japan | βiS 40/2000 /βiS 40/2000 /βiS 40/2000B |

| 4 | X、Y、Z Shaft lead screw bearing | 1 group for each | Germany FAG / Japan NSK | 50 x 100/40×90 |

| 5 | X-axis ball screw | 1 group for each | Japan THK / Taiwan HIWIN / PMI | GQ63×12-C3 |

| 6 | Y-axis ball screw | 1 group for each | Japan THK / Taiwan HIWIN / PMI | GQ50×10-C3 |

| 7 | Z-axis ball screw | 1 group for each | Japan THK / Taiwan HIWIN / PMI | GQ50×10-C3 |

| 8 | X-axis linear guide rail | 2strip | Germany INA/ TaiwanHIWIN/PMI | 55(8slider) |

| 9 | Y-axis linear guide rail | 2strip | Germany INA/ TaiwanHIWIN/PMI | 55 |

| 10 | Z-axis linear guide rail | 2strip | self-control | quench |

| 11 | Tool magazine | 1 set | Okada | 24 disc type |

| 12 | Automatic lubrication system | 1 set | Proton | 4L |

| 13 | Main pneumatic components | 1 set | gold plate | |

| 14 | Main electric components | 1 set | Schneider | |

| 15 | Main drive toothed belt | 1group | JapanUNITTA | |

| 16 | air conditioner | 1set | Commissure width |