Description

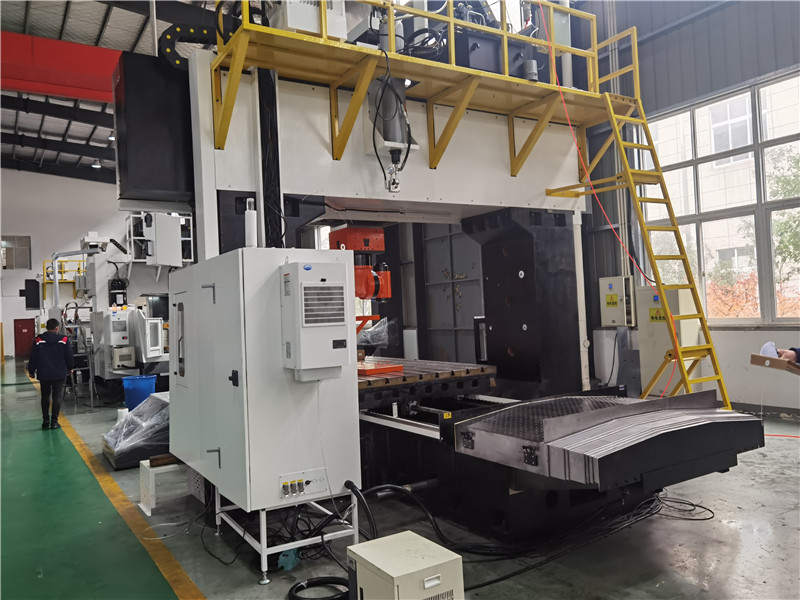

new design cnc machining center GMC1611 double column cnc gantry machining center

Specifications | Units | GMC1611 |

Table size | mm | 1800×800 |

X axis travel | mm | 1600 |

Y axis travel | mm | 1100 |

Z axis travel | mm | 600 |

Distance from spindle axis to column surface | mm | 406.5 |

Distance between spindle nose and worktable surface | mm | 140-740 |

Columns distance | mm | 1100mm |

Distance between table and cross beam | 937 | |

T slot(number-width-pitch) | 5-18×140 | |

Max. spindle speed | rpm | 8000 |

Spindle taper | mm | BT40 (Optional:BT50 ) |

Main motor power | kw | 15/18.5 |

Guide rail type | Linear rail | |

X/Y/Z rapid traverse speed | m/min | 12/12/12 |

Max.table load | Kg | 2500 |

Distance from table to floor | mm | Around 800 |

Cutting feed speed | mm/min | 1-10000 |

Positioning accuracy | mm | ±0.005/300 |

Repeat positioning accuracy | mm | ±0.004 |

Tool magazine | Arm 24 | |

Max. tool diameter | mm | φ78 (Adjacent)/ φ120(Apart) Optional: φ112 (Adjacent)/ φ200(Apart) |

Max.tool weight | kg | 8 (Optional: 18) |

Machine weight | kg | 13000 |

Overall dimension | mm | 4500x3000x3600 |

1. machine main purpose

This machine is suitable for CNC milling, boring, drilling, tapping, machining steel, steel castings, cast iron pieces. The attachment of the machine head can be used to process many kinds of processes such as drilling, milling, boring, expanding, reaming, tapping and so on for various kinds of plates, plates, housings, dies and other complicated parts in a single clamping. Parts of the efficient processing and manufacturing, the complex, high-precision machining of parts more of its superiority, but also the composition of automatic production lines for mass production, to ensure the quality of parts and efficient production.

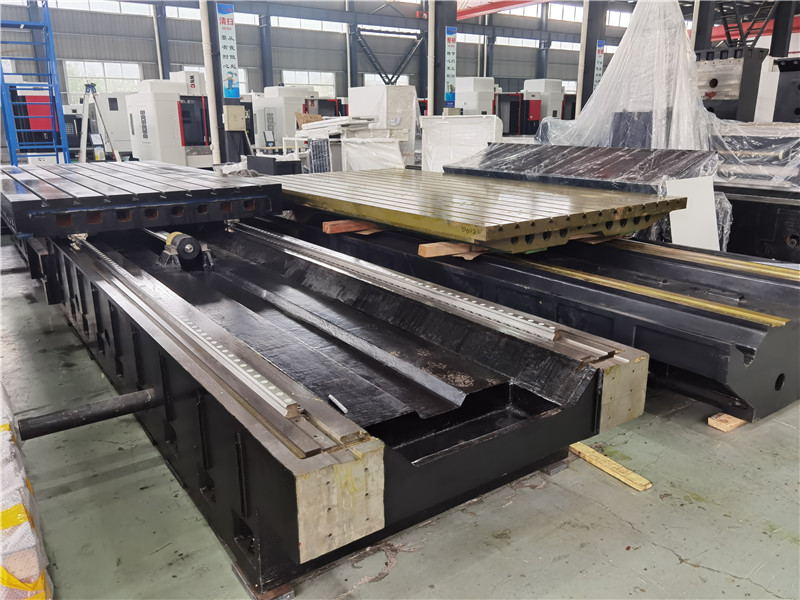

2 machine tools

The machine is a fixed beam gantry milling machine, the bed, table, beams, columns, slides, ram and other major components and balance system, electrical system. The structure of the machine tool is designed reasonably. The main basic parts such as bed, worktable, beam, column, slide seat and ram are molded by resin sand molding, and after heat aging and vibration aging treatment, there are enough static, dynamic and thermal rigidity, Good wear resistance, thermal stability, vibration resistance, to ensure

that the system has a good dynamic quality, stability for machine tools to provide a guarantee to ensure the long-term stability of the machine to use, so that the machine for a long period of continuous high-speed stability.

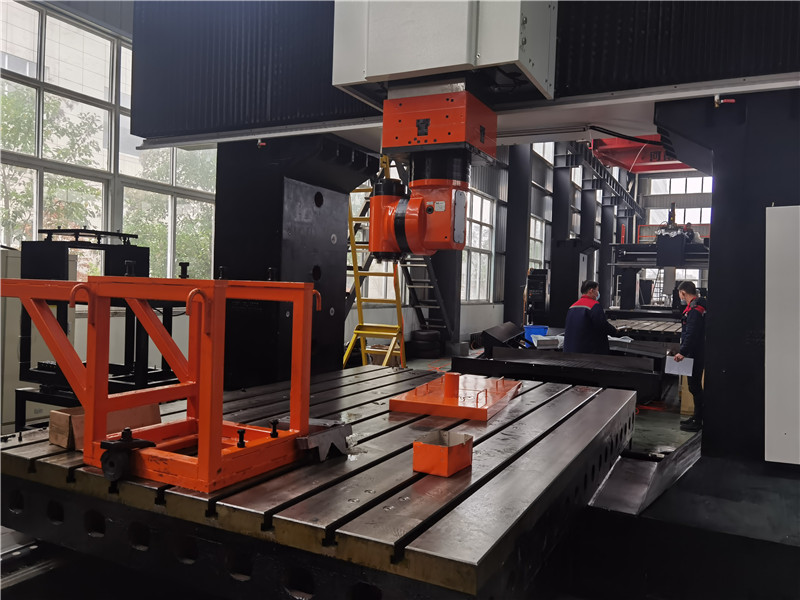

3 main structure of the machine

The spindle of the machine tool adopts high-precision spindle assembly, belt type milling head, the spindle is driven by servo motor. X, Y, Z three-axis servo control, the use of direct-coupled structure, with automatic lubrication system to achieve high-speed machine tool movement; X, Y, Z three directions feed using high-precision high-strength ball screw feed speed The drive motor is directly connected with the lead screw through a flexible coupling. The feed servo motor directly transmits the power to the high-precision ball screw without backlash to ensure the positioning accuracy of the machine tool.

3.1 spindle Taiwan’s well-known brand of high-speed, high precision, high rigidity spindle unit, axial and radial load capacity, speed up to 6000rpm; spindle blowing center structure, the center of the knife quickly after the center of high pressure gas spindle taper Cleaning, to ensure the accuracy of the tool holder;

3.2 X, Y, Z three-axis servo control, using Taiwan’s high-precision high-strength ball screw direct connection structure,

pre-tension screw installation, the connection rigid, high feed speed; feed servo motor directly to the power transmission To high-precision ball screw, no backlash, to ensure the positioning accuracy of the machine. Z-axis hydraulic balance device to ensure the same up and down movement of the driving force,

3.3 X, Y, Z three directions rails, screws are used sealed to ensure that screw and rail cleaning to ensure that the machine’s transmission and movement accuracy;

3.4 machine protection outside the ring closed structure design, safe and reliable;

3.5 Machining center configuration: Taiwan’s high-quality 16 or 20 knife umbrella-shaped magazine, the shortest path tool change, accurate tool change, short time, high efficiency, the operation test, in line with the reliability requirements;

3.6 using centralized automatic lubrication device, timing, quantitative automatic intermittent lubrication, stable and reliable work;

3.7 machine electrical wiring system neat, reasonable structure, good electrical box sealed with a heat exchange system to ensure a good environment for use;

3.8 CNC system (FANUC, MITSUBISHI, SIEMENS and GUANGDIAN) is optional; the system has perfect and reliable interlocking, safety protection and fault diagnosis alarm functions, with RS232 standard communication interface;

3.9 The machine easy to operate, flexible and fast.

4 machine working environment

4.1 Power: Three-phase AC 380V ± 10% 50HZ ± 1HZ

4.2 Ambient temperature: 0 ℃ ~ 40 ℃

4.3 Relative humidity: ≤ 90%