Description

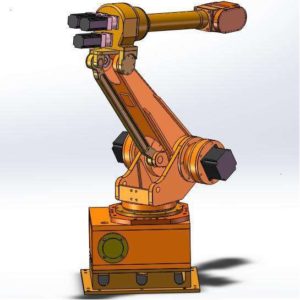

MIG TIG MAG automatic welding 6 Axis welding robot metal welding robot 6 axis

MIG TIG MAG automatic welding 6 Axis welding robot metal welding robot 6 axis

Welding robot information:

| Model | PB 1400 | |

| Payload | 6kg | |

| Max Working Radius | 1441.5mm | |

| DOF | 6axis | |

| Body Weight | 160kg | |

| Reducer Brand | Italy RRRobotica | |

| Motor Brand | Italy RRRobotica | |

| Drive Brand | Italy RRRobotica | |

| Rated Power | 2.5kw | |

| Max Speed | J1 | 149°/s |

| J2 | 149°/s | |

| J3 | 149°/s | |

| J4 | 229°/s | |

| J5 | 180°/s | |

| J6 | 270°/s | |

| Max Operation Area | J1 | ±170° |

| J2 | 153°~-92° | |

| J3 | 80°~-100° | |

| J4 | ±140° | |

| J5 | ±120° | |

| J6 | ±360° | |

| protective specification | 43 | |

| Position Repeat Accuracy | ±0.06mm | |

| controller | TRC3C-B06 | |

| Working Temperature | 0~45° | |

TURIN Welding Robot Features:

Welding Robot TKB1400:

Features

Flexible installation method:

TKB1400 Robotic arm span is 1441.5mm 6kg Payload. It can be installed on the ground or upside down flexibly

Excellent price / performance ratio

Product structure design rigorous, the key components are from first-class suppliers, superior product performance. Superior acceleration and deceleration performance, help to shorten the working time, improve production efficiency.

High-end configuration:

The robot’s core components are all imported brands (reducer: 1/2/3 axis, Japan’s Nabtesco; 4/5/6 axis Japan’s new treasure. Servo Drive: South Korea LS. Drive Motor: 1/2/3 Axis, South Korea LS; 4/5/6 axis, Japan Tamagawa), and the use of the most advanced EtherCAT bus technology, with high speed, high precision, good stability, long hours 24 hours continuous operation.

Easy to operate and programming:

Through the intuitive and friendly teaching pendant, robotics and arc welding process can be easily programmed and maintained. The teach pendant uses a popular PC graphical interface, no matter whether the robot is controlled or the specific process equipment, the operator has no stranger feeling.

Quick support and service:

Proactive and timely customer service, regular maintenance. Spare parts quality and cheap, can be quickly replaced. High-quality service for your production escort.

6 axis welding robot with the rotary welding table: