Description

Heavy duty 4 column hydraulic deep drawing press pressing machine 500ton 600ton 800ton 1000ton

Video link:

1)Introduction to the structure and properties:

The Hydraulic press has three-beam and four-pole structure, which means economical and practical. Operation space is wide, and the movable bolster could be moved out of frame to set the die. The structure is simple and the appliance is also beautiful. Hydraulic control adopts plug-in valve system, which means reliable motion and long service life. The press,, which could realize three-operation mode: adjustment, manual and semi-automatic. The machine is applicable for metal sheet stretching and pulling, stretching, punching, bending. It is also used for pulling, stretching and pressing large-scale products. Presses offer fast, easy, and safe setup and operation as well as years of trouble-free service.

2)Technical Features:

1、4-post frame provides maximum rigidity and minimum deflection for accurate parts and long tool life. Thick plates and large columns provide you with the stable platform you need for your demanding application.

2、Long bearing length offer improved stability and resistance to off-center loading.

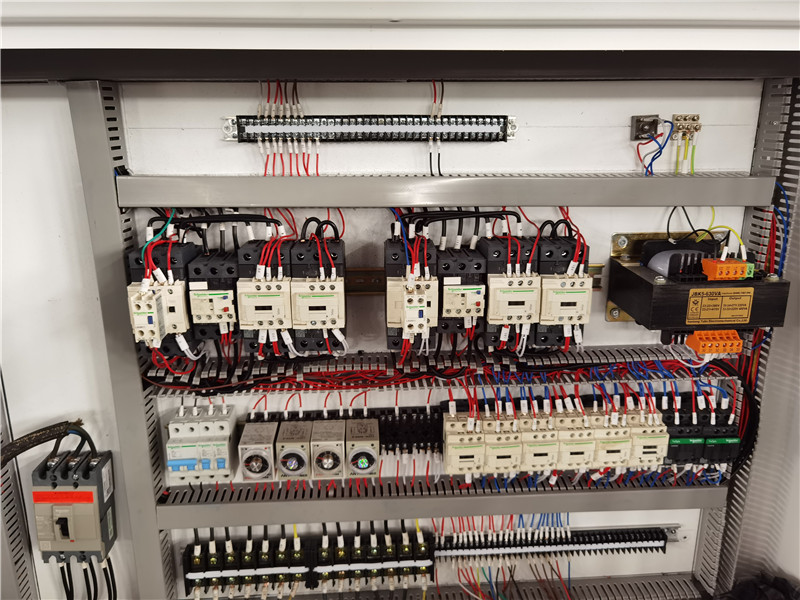

3、PLC press control is flexible and safe. PLC controls allow for customized press cycles.

3) Standard specifications:

| Type(YL32) | Unit | 315Tons | 400 Tons | 500Tons | 630Tons | 800Tons | 1000Tons | 1600Tons | 2000Tons | ||

| 1 | Rated Nominal Pressure | KN | 3150 | 4000 | 5000 | 6300 | 8000 | 10000 | 2*8000 | 2*10000 | |

| 2 | Knock Out Force | KN | 630 | 630 | 1000 | 1000 | 1000 | 1600 | 2*1000 | 2*1600 | |

| 3 | Back Stroke Pressure | KN | 600 | 500 | 900 | 850 | 1000 | 1300 | 2*720 | 2*1300 | |

| 4 | Ram Stroke Length | mm | 800 | 800 | 900 | 900 | 1000 | 1000 | 1200 | 1300 | |

| 5 | Knock Out Stroke | mm | 300 | 300 | 350 | 350 | 350 | 350 | 350 | 500 | |

| 6 | Max.Opening Height | mm | 1250 | 1250 | 1500 | 1500 | 1800 | 1800 | 1800 | 1800 | |

| 7 | Ram speed | Idle Stroke | Mm/s | 100 | 100 | 100 | 100 | 120 | 110 | 120 | 110 |

| Work | Mm/s | 5-12 | 4-10 | 7-15 | 5-12 | 5-12 | 5-12 | 4-9 | 4-9 | ||

| Return | Mm/s | 60 | 70 | 80 | 85 | 95 | 85 | 95 | 70 | ||

| 8 | Knock out speed | Knock out | Mm/s | 55 | 55 | 75 | 75 | 95 | 75 | 70 | 60 |

| Return | Mm/s | 145 | 145 | 170 | 170 | 170 | 210 | 160 | 160 | ||

| 9 | Work Table size | L-R | mm | 1260 | 1250 | 1400 | 1600 | 2200 | 2500 | 2800 | 3200 |

| F-B | mm | 1160 | 1250 | 1400 | 1600 | 1600 | 1800 | 2000 | 2200 | ||

| 10 | Outline dimensions | L-R | mm | 3500 | 3500 | 3900 | 4510 | 4800 | 5100 | 5600 | 4500 |

| F-B | mm | 1500 | 1600 | 2150 | 2250 | 2400 | 2400 | 2600 | 3200 | ||

| Height | mm | 4600 | 4850 | 5200 | 5400 | 5700 | 6000 | 6200 | 7200 | ||

| 11 | Motor Capacity | Kw | 22 | 22 | 2脳22 | 2脳22 | 2脳30 | 3脳22 | 3脳30 | 3脳37 | |

| 12 | Weight of the Machine | Kg | 14500 | 16500 | 25500 | 33000 | 53000 | 72000 | 110000 | 160000 | |

Parameters change without any notice, if you do not find your need in the tables just contact us.