Description

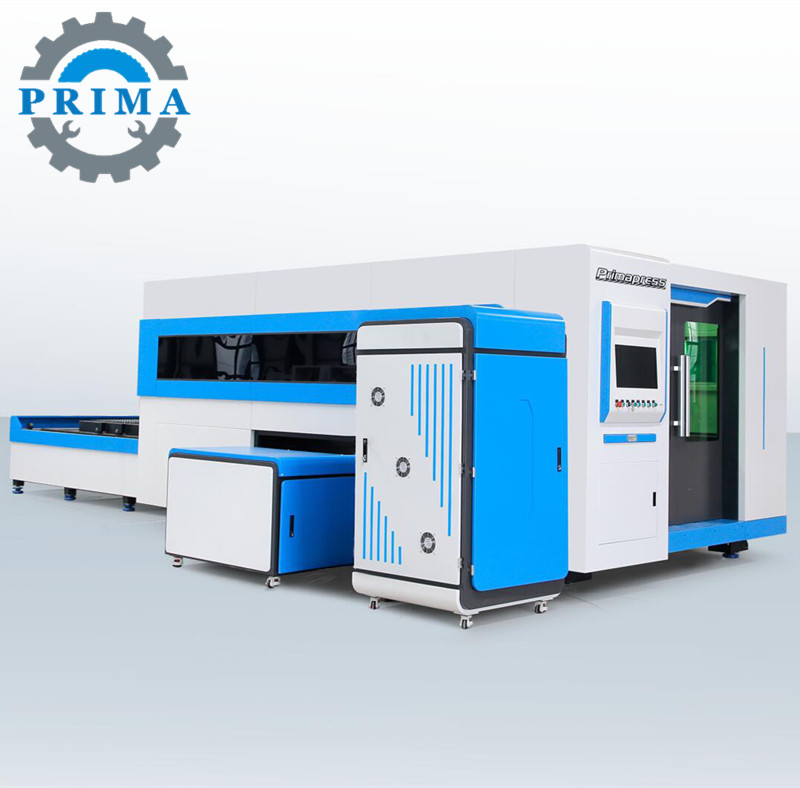

IPG source Exchange Table CNC Fiber Laser Cutting Machine with 1kw to 6kw

Application:

Fiber laser cutting machine widely used for high-speed, high-precision cutting of metal sheets such as carbon steel, stainless steel, spring steel(60,65,65Mn,70), alloy steel, galvanized steel sheet, aluminium sheet, etc.

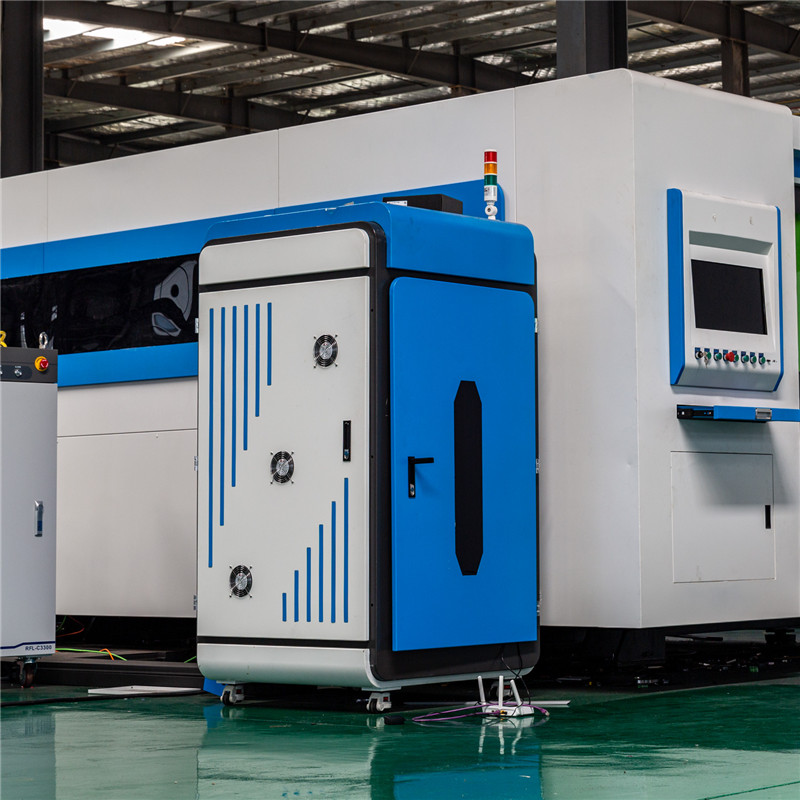

Fiber Laser Cutter consists of laser generator, control system, motion system, optical system, cooling system, fume-extraction system, it adopts famous brand servo motor and transmission and guide structure with excellent performance to achieve good motion accuracy in high-speed state

Technical Parameter:

| Item | Parameter | 500W | 1000W | 2000W | 3000W |

| 1 | Laser Generator | Imported or made in China Optional | Imported or made in China Optional | Imported or made in China Optional | Imported or made in China Optional |

| 2 | Laser Wavelength | 1070nm | 1070nm | 1070nm | 1070nm |

| 3 | Laser Repeat Frequency | CW | CW | CW | CW |

| 4 | Mechanical driving system | Rack&Pinion, ATLANTA, German | |||

| 5 | PC System | Industrial control,EVOC, Taiwan | |||

| 6 | X axis servo unit | 1000W servo single driving, Fuji, Japan | |||

| 7 | Y axis servo unit | 2000W servo dual driving, Fuji, Japan | |||

| 8 | Z axis servo unit | 400W servo single driving, Fuji, Japan | |||

| 9 | Limit switches | NPN | |||

| 10 | Min Linewidth | 0.2mm(for materials with thickness less than 0.4mm) | |||

| 11 | Max.Cutting Thickness | ≤6mm for carbon steel ≤4mm for stainless steel | ≤8mm for carbon steel ≤5mm for stainless steel | ≤16mm for carbon steel≤8mm for stainless steel | ≤22mm for carbon steel ≤10mm for stainless steel |

| 12 | Continued Working Time | ≥20 hours | ≥20 hours | ≥20 hours | ≥20 hours |

| 13 | Max.Cutting Dimension | 200*400cm | 200*400cm | 200*400cm | 200*400cm |

| 14 | Table Exchanging Time | 8seconds | 8seconds | 8seconds | 8seconds |

| 15 | Wortable Cutting Accuracy | 0.05mm/m | 0.05mm/m | 0.05mm/m | 0.05mm/m |

| 16 | Repeated Positioning Precision | ±0.05mm/m | ±0.05mm/m | ±0.05mm/m | ±0.05mm/m |

| 17 | Power Supply | Three-phase 5 wires AC 380V±5%,50Hz±1% | Three-phase 5 wires AC 380V±5%,50Hz±1% | Three-phase 5 wires AC 380V±5%,50Hz±1% | Three-phase 5 wires AC 380V±5%,50Hz±1% |

Machine advantages:

Excellent beam quality: smaller focused spot makes more efficient work and cutting quality

High cutting speed: its speed is twice of the same CO2 tube laser cutting machine

High stability, the world’s top fiber laser generator makes stable performance, and the key components of the machine owns the life up to 100,000 hours

High electro-optical conversion efficiency: fiber laser is three times higher than CO2 laser and cutting machine

Low use-cost: whole machine consume less energy, only 20%-30% of traditional CO2 laser machine

Low using cost: no laser working gas, it is by fiber-optic transmission, without lens reflecting, can save a lot of maintenance costs

Smart operation and easy to maintain: optical fiber transmission, no need to adjust the optical path

Super flexible light guiding effect: compact structure, satisfies flexible processing requirements

Features

1. Fiber laser generator is for cutting all the metal sheets.

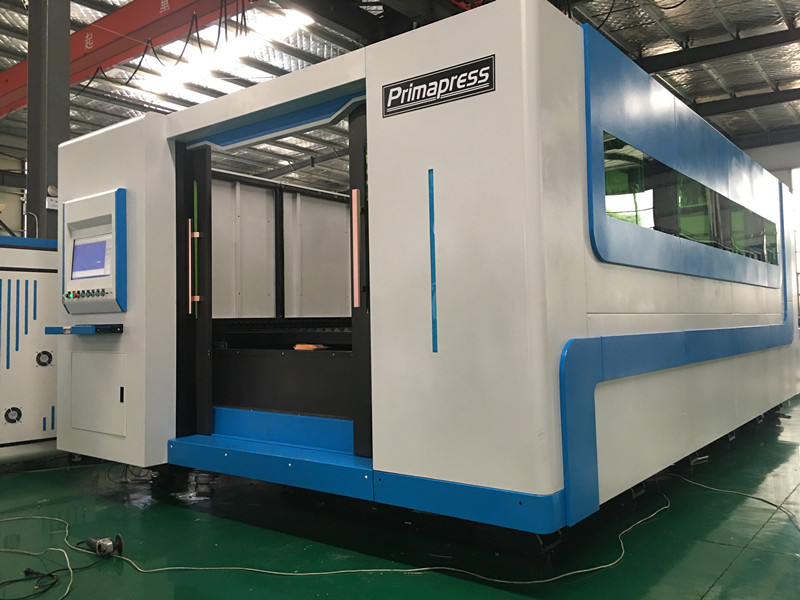

2. Gantry double drive structure and automatic exchange worktable to make the cutting more efficient.

3. Compared with YAG and CO2 laser cutting machine, fiber laser cutting machine has the processing cost advantage absolutely.

4. All the key transmission parts is originally imported from Germany(servo motor, gear and rack, reduction gear etc

5. Fully enclosed protective cover, generous appearance, and cut more security

Qingyuan Laser is well-known as one of the largest and professional exchange table fiber laser cutting machine manufacturers and suppliers in China. With a group of professional and effective personnel, we can offer you exchange table fiber laser cutting machine at low price.

#fiber laser cutting machine compact #6kw fiber laser cutting machine

#sql fiber laser cutting machine #laser fiber cutting machine head

#fiber laser cutting machine 1kw