Description

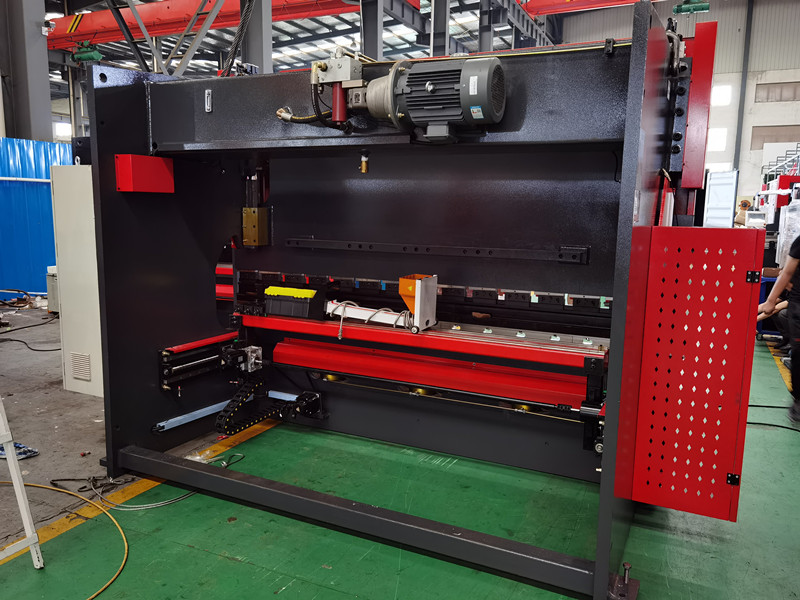

Electro Hydraulic CNC Press Brake 300t5000mm DA58T 4+1 axes Sheet metal Delem DA58T 4+1 axes Electro Hydraulic CNC Press Brake 300ton 400ton 6m 5m

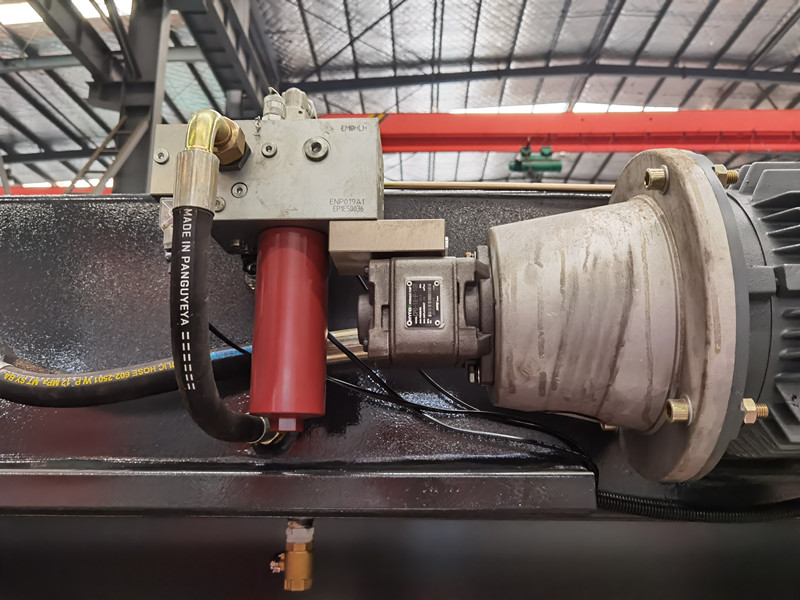

A:DA58T or DA66T+ ProNet serco+ Heidenhain Linear Encoder

DA66T can control 3 shafts synchronously to reduce the load of each shaft. Together with PRONET large-torque servo,

it can control all-electric bending machine perfectly, efficiently, precisely, energy-efficiently and steadily.

Standard Configuration :

- CNC sheetmetal pressbrake with streamlined desigh,hight speed ,hight precision,hight rigidity.

- Electro hydraulic servo system,full loop comtrolling the synchronizatio of the upperbeam.

- Equip with hydraulic crowning compensation on worktable and deformation compensation device on throat to make sure bending depth and precision.

- Backgauge is driven bu digital servo motor,moved by ball screw guided by linear guide.

What should we know for choosing a press brake ?

- What’s your material of sheet ?

- What’s the minimum and maximum thickness of your sheet ?

- What’s the minimum and maximum width of your sheet ?

- What kind of product you make ?

- What’s the precision do you require for making products ?

V-axis Table Compensation :

V-axis is the CNC axis to control the adding convex amount of workbench, it can obtain accurate deflection compensation from the workbench. The adding convex workbench is made up of a group of beveled convex wedge, each wedge slope is designed by the deflection curve of finite element analysis of the slider and workbench vertical plate. CNC controller will calculate the required deflection amount according to the load when the work piece is working (The load will lead to the deflection and deformation), automatically control the relative motion of the convex wedge, and finally get an ideal work piece.

#brake press tool #brake press elettric #harsle press brake

#press brake clamp #promecam press brake tooling