Description

CNC Full-Auto Numerical Control Single-Head pipe tube automatic Bending Machine

Machine Characteristics

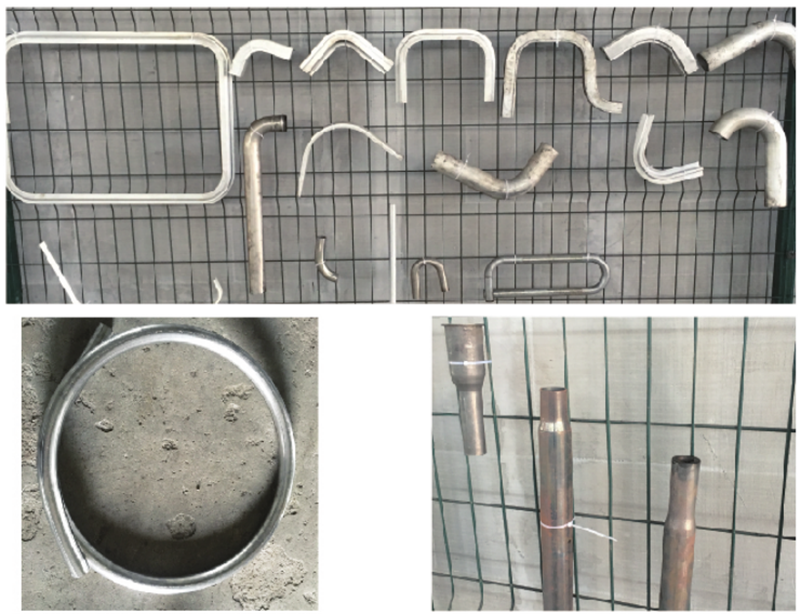

SB-CNC Series numerical control single-head pipe bending machine is the product from the combination with our technology and advanced

Italian technology, integrated with machine, hydraulic, and electricity. This series adopt touch screen operating panel, which can input, store, and display

various bending data and order. Y, B, C three coordinates of motions under precision control by industrial computer can realize full-auto mandrel on or

mandrel off rapid bending, CNC machine also with advanced functions, such as components bending spring back compensation, errors self diagnose alarm,

memory store after power off, automatic lubrication and safety protection. Pipe bending(C axis) is driven by oil cylinder, while pipe rotating (B axis)

and pipe feeding(Y axis) are both driven by servomotor. Advanced technology, high automation reliability, integrated design all make

CNC pipe bending machine the first class pipe processing machine in the world.

- Machine Characteristics

This machine is servo drove and its electronic control system adopts touch screen and PLC. It is equipped with devices of pipe clamping, guide mould, mandrel,

crease-resistant, assist pushing, pipe bending ,rotating pipe and so on. Under hydraulic operation, this professional, high speed European pipe bending machine

can bend various dimension both normal and abnormal shape metal pipes and bending angles are controlled by high precision imported encoder

which ensures high precision of this machine.

- Main Technical Parameter

| No | Name | Unit | Parameter | |

| 01 | Max bending capability:Mild steel round tube | mm | ¢63*3 | |

| 02 | Min. bending radius | mm | R≥1.5D | |

| 03 | Max. Bending radius(Standard) | mm | 300 | |

| 04 | Though Effective Distance | mm | 4000 | |

| 05 | Head overhang (on bending center) | mm | 500 | |

| 06 | Head height (on bending center) | mm | 120 | |

| 07 | Bending center height (from floor) | mm | 1050 | |

| 08 | Max. Bending Angle | ° | 190° | |

| 09 | Max. Bending Speed | °/sec | 90 | |

| 10 | Bending Angle Precision | ° | ±0.10 | |

| 11 | Feeding pipe precision | ° | ±0.10 | |

| 12 | Max rotating speed | °/sec | 180 | |

| 13 | Max curves in one pipe | curves | 20 | |

| 14 | Pipes storage capacity | pieces | 200 | |

| 15 | Hydraulic System Motor Power | KW | 5.5 | |

| 16 | Hydraulic Pump Output Volume | L | 23 | |

| 17 | Max Pressure | Mpa | 16 | |

| 18 | Oil Tank Volume | L | 320 | |

| 19 | Repeated Location Precision | Bending Axis | ° | ±0.1 |

| Diversion Axis | ° | ±0.1 | ||

| 20 | Ovality rate after processed | <8% | ||

| 21 | Thickness Reduction after processed | <12% | ||

| 22 | Tooling Center Height | mm | 55 | |

| 23 | Feeding Method | 1.clamping | 2.loosen | |

| 24 | Feeding Servo | KW | 1.0 | |

| 25 | Rotating Servo | KW | 1.0 | |

| 26 | Gross Power | KW | 8 | |

| 27 | Machine Voltage | V | As per customer’s requirements | |

| 28 | L*W*H | mm | 5000*1200*1300 | |

Configuration of Hydraulic and Electronic Control System

| No | Name | Manufacturer |

| 01 | Touch screen | Taiwan Weinview |

| 02 | PLC | Japan Mitsubishi |

| 03 | Rotating servo motor | Japan Mitsubishi |

| 04 | Feeding servo motor | Japan Mitsubishi |

| 05 | Rotating driver | Japan Mitsubishi |

| 06 | Feeding driver | Japan Mitsubishi |

| 07 | Linear guideway | SHAC(Taiwan) |

| 08 | Magnetic Valve | Japan Yuken |

| 09 | Flood Valve | Japan Yuken |

| 10 | Oil tube | Suzhou Kejia |

| 11 | integrated oil circuit | Taiwan Shanghong |

| 12 | Vane pumps | Taiwan Xinghong |

| 13 | Main motor | Suzhou Jialifan |

| 14 | Emergency Button | Omron |

| 15 | Oil tank | Shanghai Qifan |

| 16 | Other electric parts | Schneider |

| 17 | Optoelectric switch | Omron |

| 18 | Power Switches | Taiwan Meanwell |

| 19 | Relay integrated block | Custom-made |

| 20 | Transformer | Wuxi Xinyu |

| 21 | Reducer | hente |

| 22 | Bearing | Wahaluo |