Description

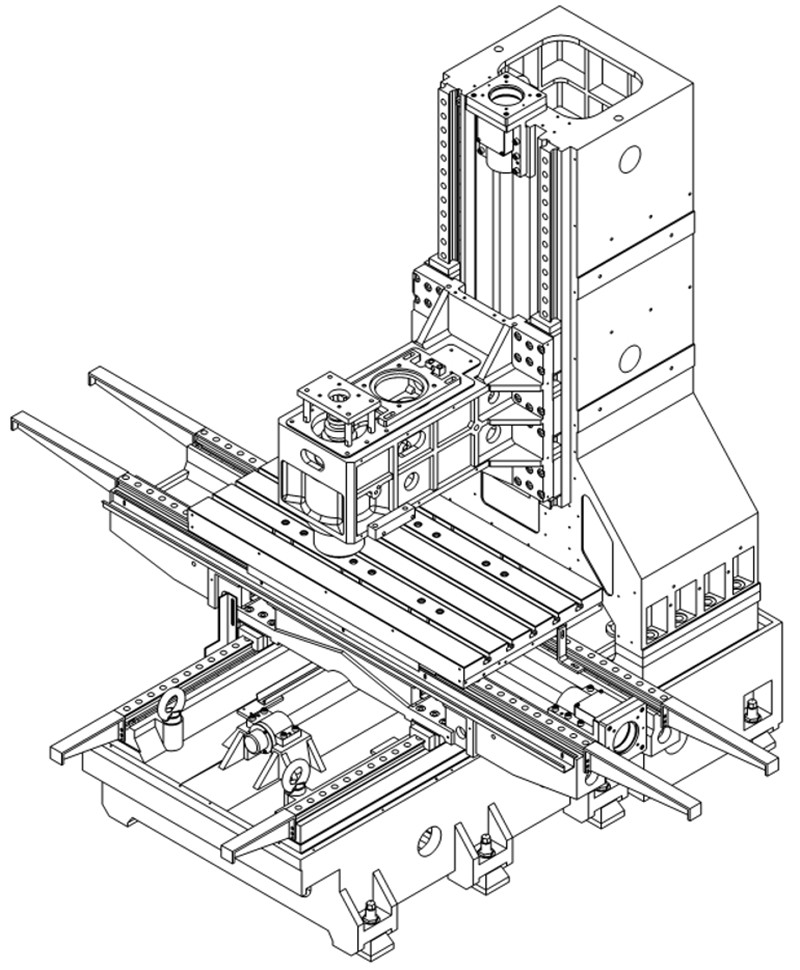

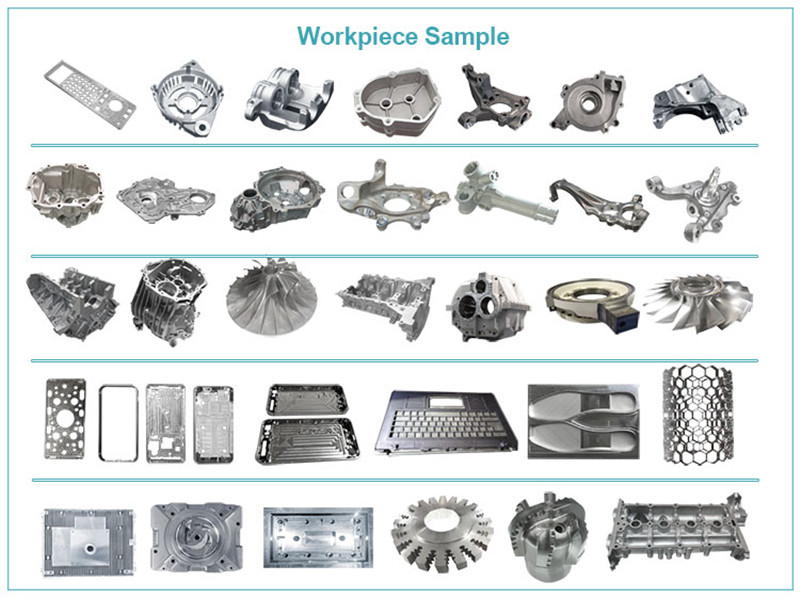

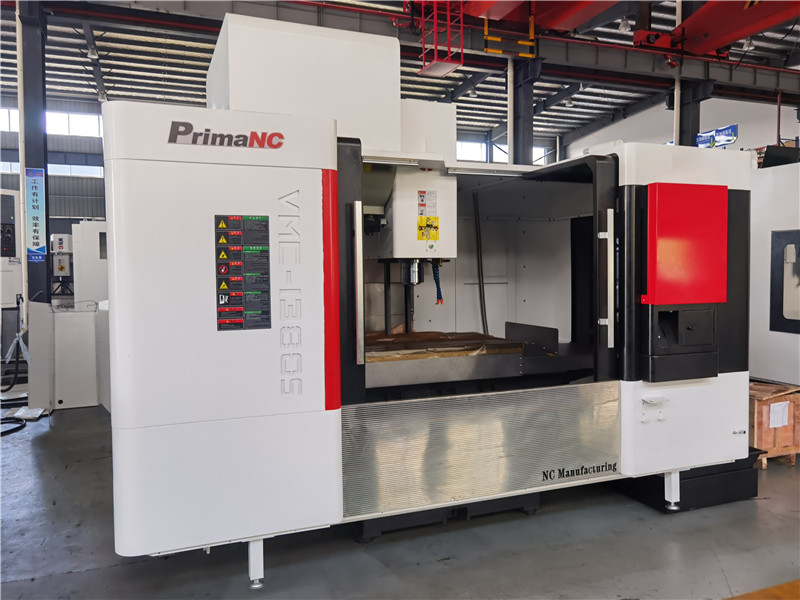

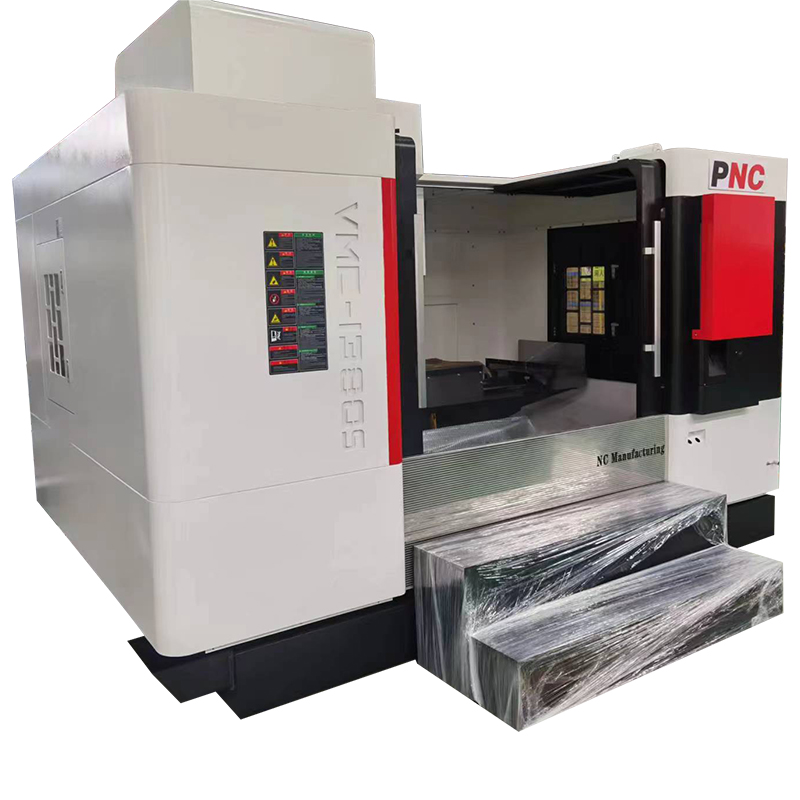

High Speed Machining Center Introduction: The machine is suitable for machining complex contours of the mold, auto parts, service industries box parts, and has its superiority in the mold processing .And it is the best choice for small mold parts processing industry. With low speed high torque, it is suitable for high-strength steel, high temperature alloys and other difficult materials and complete efficient processing of steel parts. High Speed Machining Center Features: High precision cnc vertical machine center The X, Y and Z axes lead screw of the machine used advanced media altitude cooling system, which controls the transformation during the machining process and improves the machining precision. Besides, it has the function of temperature compensation. With temperature sensor part and CNC system, this machine can work with high precision. High speed machine center The spindle uses variable speed gear transmission structure which can provide low and high speed machining work at the same time. X, Y and Z axes were designed with high steel nature import pasting plastic boardquench guide way sliding pair. High steel performance vertical machine center The main body of the machine was used resin sand high strength cast. The column , sliding table and the worktable move on the lathe body. Besides, the machine has rational structure by designed through finite element.

Model | VMC650 (GSK25i system) |

Travel parameters of 3 axis | |

X/Y/Zaxis travel | 650/450/500mm |

Spindle face to table distance | 70-520mm |

Distance between spindle center and column guide surface | 420mm |

Worktable parameters | |

Worktable size | 800/450mm |

Maximum load bearing of worktable | 450kg |

T Shot | 3/16/110mm |

Feeding parameters | |

X/Y/Z axis rapid movement rate | 24/24/16 m/min |

Feed moving velocity X, Y, Z | 1-10m/min |

Spindle parameters | |

Main shaft connection | Belt |

Spindle taper | BT40-120 |

Range of spindle speed | 8000rpm(Optional:10000 ) |

Spindle motor power | (Alternating current servo)5.5kW |

ATC paremeters | |

ATC capacity | 16qty |

Maximum tool size | 92mm(tool from a distance) |

Maximum tool weight | 5kg |

Precision | |

PositionaI accuracy(JIS standard) | 0.008/300mm |

Repeated positioning accuracy(JIS standard) | 0.005mm |

Shape and weight | |

Machine size :2500/2100/2360mm | Weight :3800kg |

Standard accessories | |

GSK 25i CNC System | Bt40-120-8000rpm belt spindle |

Machine tool lighting working lamp | Centralized automatic feed lubrication system |

Spindles clean the air | Spindle taper: BT40 |

Chip liquid system | Tricolor warning light |

Servo transformer | RS232 interface |

Foundation gasket and adjusting bolt | Three ball type linear guide rail |

Random technical document | Three-axis precision grinding ball screw |

Electrical cabinet cold and heat exchanger | |