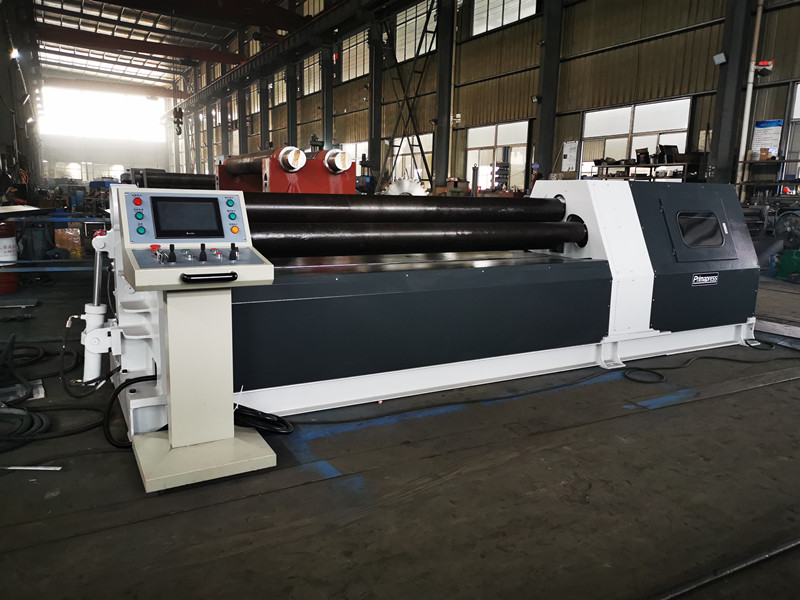

Principle and maintenance process of metal plate CNC four-roller bending machine

PrimaPress CNC four-roller coiling machine has a variety of rolling processes, and users can decide according to their own process. One of them is provided below:

1. Operate the lower roller to rise so that the bus bar is slightly larger than the working thickness from the lower bus bar of the upper roller, and then operate the

feeding side roller to make the upper bus bar on the same level, and then operate the other side to rise between the upper and lower rollers.

2. Feeding: Feed the steel plate horizontally, so that the end of the steel plate is in full contact with the front roller for alignment, and then lower the front

roller to its original position.

3. Tighten the steel plate and pre-bend the end: according to the thickness and material of the steel plate, adjust the pressure of the lower roll circuit to a value

within a specific range, operate the lower roll to lift and clamp the steel plate, start the upper roll to rotate, and when the steel plate moves to the bending position

The upper roller stops rotating. At this time, the left end of the center line of the upper and lower rolls should be left with the necessary tightening length approximately

equal to 1.5 times the plate thickness. Then raise the rear roller to pre-bend the end of the steel plate.

4. Pre-bend the other end of the steel plate with the front roller. After the left end is pre-bent, lower the rear roller to its original position and start the upper roller.

When the steel plate moves to the above-mentioned bending position, the upper roller stops rotating. Operate the front side roller to raise the other end of the

pre-bent steel plate, and then adjust the pressure of the roller circuits on both sides.

5. Preliminary bending: adjust the front and rear side rollers to the corresponding positions required by the work, and start the upper roller for final forming and bending

6. Forming and bending: Take out the workpiece: After the bending is completed, lower the lower roller to the lowest position, the workpiece will be lowered to a certain

position along with the rollers on both sides at the same time, turn the head upside down, lift the workpiece parallel to the upper roller, take out the workpiece, and complete a work cycle .

Compared with the symmetrical three-roller, the four-roller can directly pre-bend the end of the plate without the help of other equipment molds, and the

remaining straight edges are smaller; compared with the asymmetrical three-roller, it can eliminate the plate U-turn, it can be rolled into a workpiece.

This not only improves the efficiency, guarantees the quality of the workpiece, but also has simple process and convenient operation, which reduces the labor intensity of workers.

When using a four-roller bending machine, the following operations should be followed to prevent unnecessary safety accidents.

1. If the four-roller bending machine is found to have abnormal noise, impact, oscillation, leakage, etc. and the temperature of the hydraulic oil, motor, and bearing is too high (>60℃),

it should be shut down immediately for inspection and treatment.

2. When using a sample plate to check the roundness, it must be carried out after the four-roller bending machine stops.

3. It is forbidden to take the head and overload when the steel plate is rolled. Personnel operating the four-roller coiling machine must stand on both sides of the steel plate to be coiled.

The four-roller coiling machine (the effective working surface of the upper roller) must not stand on the front and back, and no one should stand on the plate during rolling to

avoid the steel plate from sticking out. Or fall and hurt people.

4. The rolled plate standard should not exceed the scale of the four-roller rolling machine operation manual and capacity curve rules. Do not adjust the pressure of the

upper roller at will, and the operator must pay attention to observe the operating conditions.

5. All rolled plates must be placed in the center of the roller for rolling. No slipping is allowed during the rolling process.

6. During the process of steel plate coiling and restriction, the operator must always observe the operating condition of the plate. The plate must not be rolled off.

When the length reaches the end, when the symmetrical coil is formed beyond the radius, no personnel are allowed to enter the job site in the direction of the opening.

7. When the overturning frame is overturned, it is necessary to confirm that the horizontal direction of the upper roller is in the middle position. It can be overturned only when the vertical direction is at the highest point, and the upper roller cannot be moved horizontally when the upper and lower rollers are in contact.

8. When starting the welding of the cylinder on the four-roller bending machine, the ground wire of the welder must be in good contact with the cylinder to be welded.

The above is what we want to share and understand today about the use of the four-roller bending machine.