Price and Features of Flexible Bending Center Multilateral panel Bending Machine

The price of Multilateral panel Bending Machine? It can be said that different manufacturers have different prices because of different materials. The price of different models of the same manufacturer is also different, welcome to inquire us.

The flexible bending center can work independently and can efficiently produce parts of various specifications. The general mold can be automatically adjusted according to the size set by the program without any adjustment time, which ensures the safety of the operator and the quality of the product.

The positioning process is only completed once at the beginning of the entire bending. It is operated in this cycle, and the bending plate and the rotating structure remain unchanged. The resolution of 0.01 degrees ensures high production flexibility.

Flexible Bending Center Flexible Bending Machine Full Servo Multilateral panel Bending Machine Cabinet Door Automatic Tool Change Bending Center

Flexible Bending Center Flexible Bending Machine Full Servo Multilateral panel Bending Machine Cabinet Door Automatic Tool Change Bending Center Features are as follows:

Flexible and universal bending tool

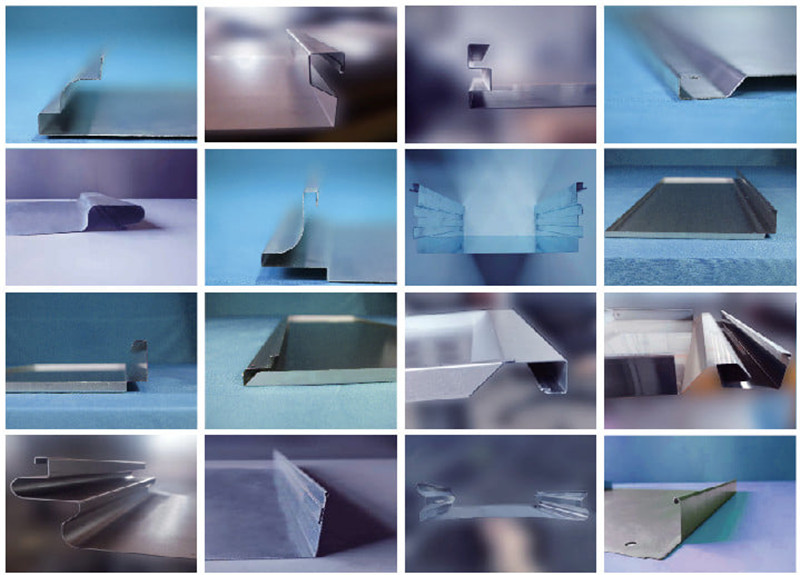

Using the general bending die with optimized properties and the special kinematics system to process, the sheet bending thickness is from 0.5-3.2 mm.

High productivity, self-adjusting design

The automatic adjustment device for the length of the upper feeder automatically adjusts the length of the feeder without occupying any production time.

Intelligent, stable workpiece quality

The proprietary plate property compensation technology enables the multilateral bending center to use various changes in plate properties to ensure the consistency of workpiece quality.

The flexible bending center focuses on solving various complex sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is solved from a technical point of view, effectively improving production efficiency and reducing production costs.

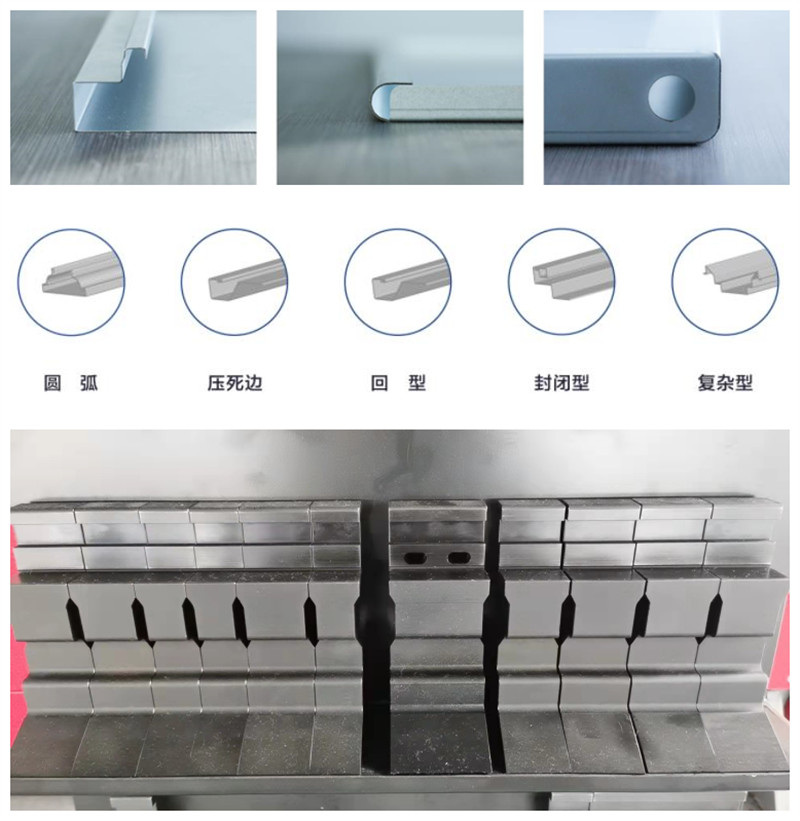

Easily realize the bending requirements of circular arc, dead edge, return type, closed type and other complex types of sheet metal.

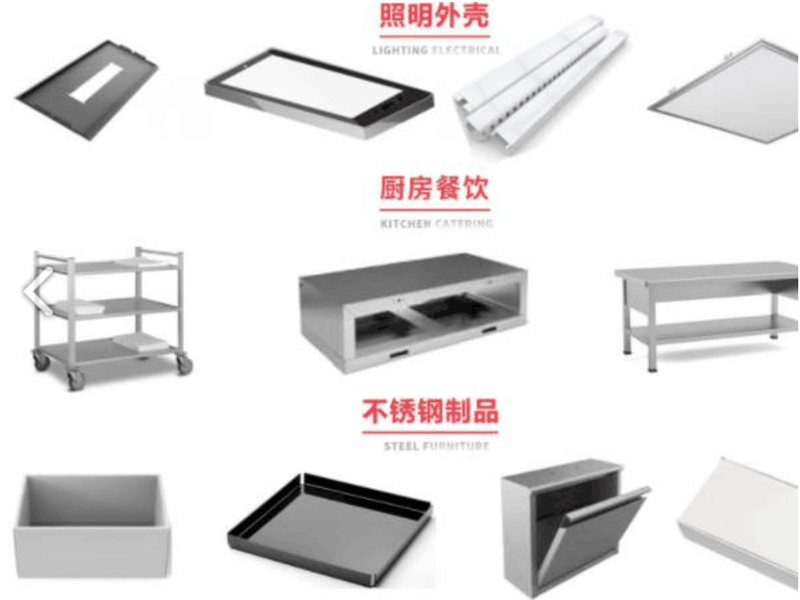

The flexible bending center can be widely used in the field of steel cabinet shells (file cabinets, tool cabinets, outer shields, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets…), kitchen utensils (refrigerators, air conditioners, cookers…) , furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields.

How much is a fully automatic bending machine

How much is a fully automatic bending machine? This first depends on the model of the automatic bending machine? That is to say, specific functional requirements, equipment solutions are formulated according to the requirements, and quotations are made according to the solutions.

The flexible bending center focuses on solving various complex sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is solved from a technical point of view, effectively improving production efficiency and reducing production costs.

Easily realize the bending requirements of circular arc, dead edge, return type, closed type and other complex types of sheet metal.

Prima flexible bending center can be widely used in the field of steel cabinet shells (file cabinets, tool cabinets, outer shields, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets…), kitchenware fields (refrigerators, air conditioners, stoves …), furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields.

Multilateral panel Bending Machine AT-S2500 is the company’s technical research and development department after 2 years of technical research, committed to developing a servo flexible bending center with international level, the bending speed is only 0.2 seconds per knife, the equipment can be automatically according to the bending process The up-folding and down-folding actions can realize the combined bending of arc, dead edge and various angles. Various bending requirements can be achieved without changing the bending tool, which saves a lot of labor and mold costs for the enterprise.

The maximum processing plate size is 2500mmx1500mm, control X, Y, C, V1, V2, Z1, Z2, W1, W2, P a total of 10 axes.

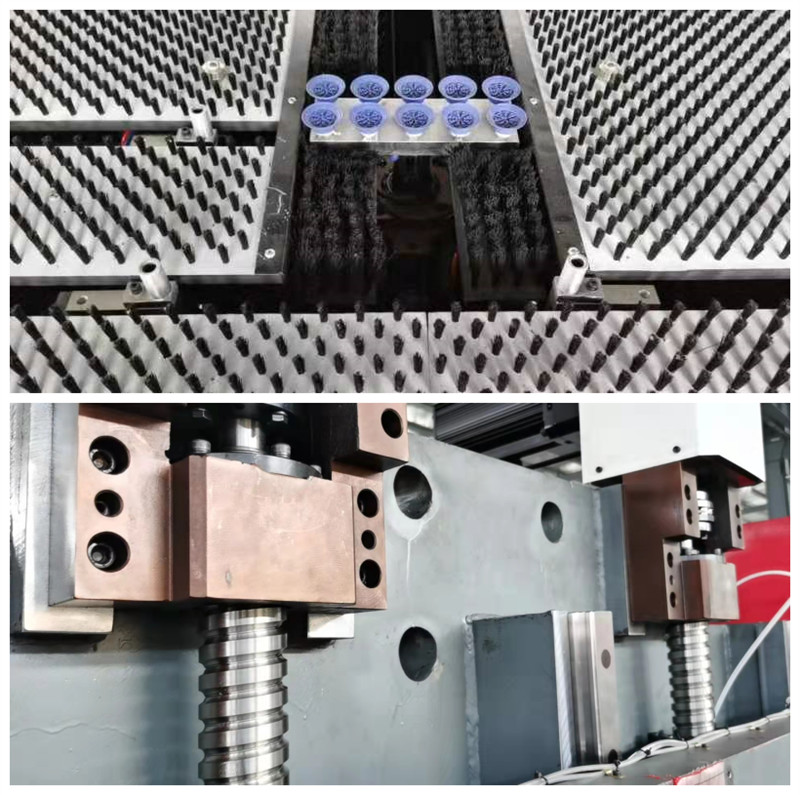

It adopts C-shaped pressing arm structure, and the end adopts a crank connecting rod mechanism to drive the presser foot to press down, press the plate, and realize the feeding method of moving and rotating the plate.