Precautions for the use of hydraulic combined ironworker punching and shearing machines

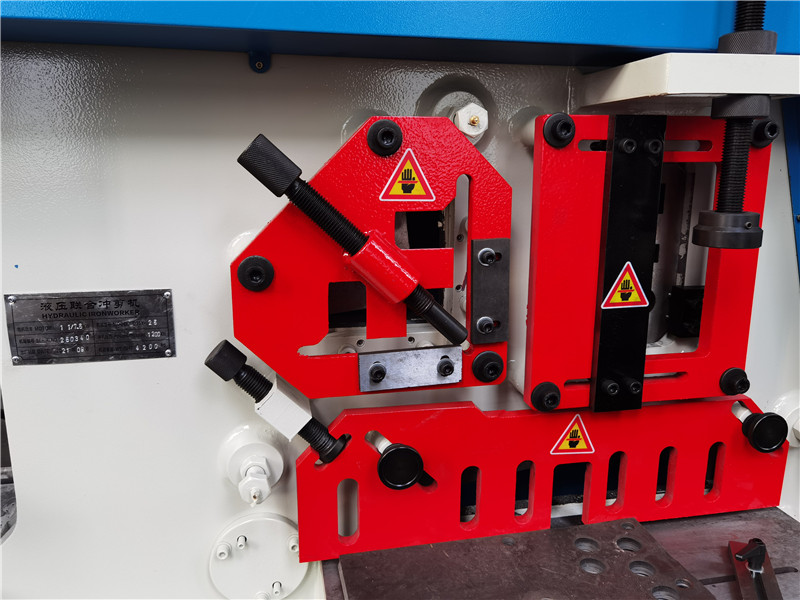

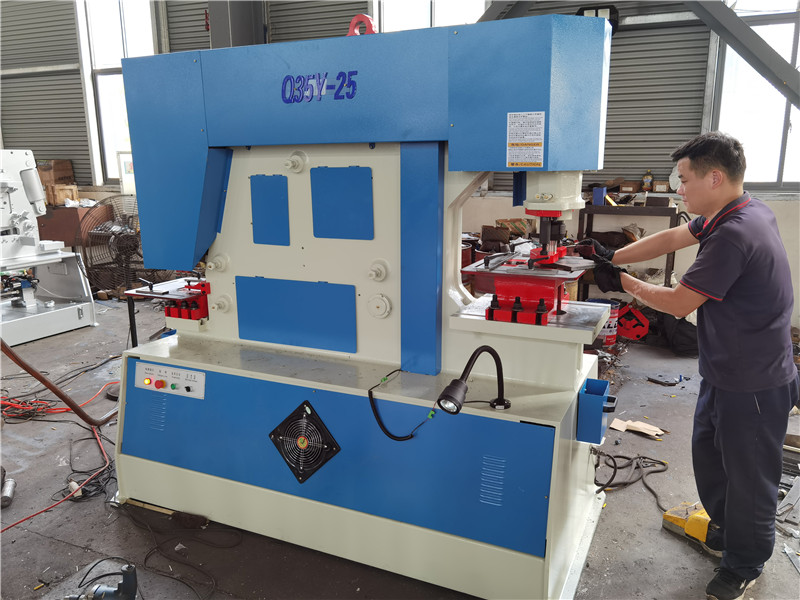

combined ironworker punching and shearingmachine is a common machine tool equipment in the mechanical processing industry, which can be used for metal cutting, punching, etc. It is easy to operate, low energy consumption, and is an essential equipment in modern manufacturing metal processing. According to different functions and principles, combined ironworker punching and shearingmachines are also divided into hydraulic combined ironworker punching and shearingmachines and combined combined ironworker punching and shearingmachines. Today, the editor will tell you what to pay attention to when using hydraulic combined ironworker punching and shearingmachines.

Firstly, hydraulic combined ironworker punching and shearingmachines, as an industrial facility, have certain risks. Therefore, operators must strictly follow the mechanical safety operating procedures. Before operating, they must first familiarize themselves with the structure and performance of the machine tool, receive training and be qualified before starting work.

Before operating the hydraulic combined ironworker punching and shearingmachine, it is necessary to wear labor protective equipment. Before starting to use, it is necessary to check whether the power voltage and other requirements meet before starting the machine. Only when there is no suitable person around the working range of the machine can operation be carried out. When someone approaches, the speed must be set to zero and the stop button pressed.

After use, it is necessary to cut off the power supply of the hydraulic combined ironworker punching and shearingmachine, and clean the machine tool and work site.