Operation process, precautions and maintenance details of metal sheet plate CNC rolling bending machine

The operator must be proficient in operating the plate rolling machine to realize the working principle and maintenance

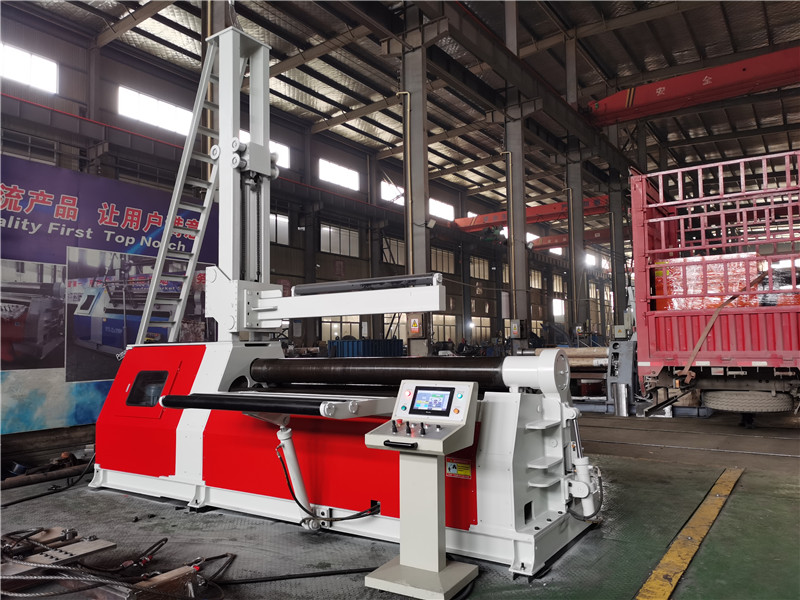

The main structure of the equipment of the metal sheet plate CNC rolling bending machine is the main body, the hydraulic station and the electrical control cabinet. When working, the electric oil pump will output high pressure oil first, and then send the high pressure oil to the coil. In the working cylinder of the machine, the winding machine is also equipped with an electric motor. The high-pressure oil will push the plunger in the motor to generate power, so that the processing purpose can be achieved.

After the metal sheet plate CNC rolling bending machine works, the forming effect is very good, the efficiency is high, and the working speed is also very fast. It should be installed on a hard surface when installing. The metal sheet plate CNC rolling bending machine can maintain smooth work, and when working hard, it is also necessary to strictly abide by the rules and regulations and related operating procedures. The operator must operate the sheet metal plate CNC rolling bending machine to realize the working principle and maintenance. Master it.

The maintenance and service life of the metal sheet plate CNC rolling bending machine have a very important relationship. In the process of use, as long as the maintenance is continued, the relevant work can be ensured during startup and shutdown, making the use more smooth. Work can be done in a series of operations in these sequences. The sales of sheet metal plate CNC rolling bending machines are getting higher and higher in some of the current machinery sales markets. For this type of machine, it is becoming more and more popular among those who use it in many factories, not only because of the manipulation of the product during use. It’s simpler, and more because it increases the efficiency of the plant. First of all, it can ensure that we do not need too many professionals to operate it when using it. General workers can handle the product. Moreover, the use of metal sheet plate CNC rolling bending machine is not particularly complicated. For manufacturers who also consider the growing demand for such products when producing such products, they want to be different. Customer needs are categorized. Some customers want these products to be easy to handle, which saves time and does not require hiring a metal sheet plate CNC rolling bending machine professional to perform such products.

The precautions for the safe operation of the metal sheet plate CNC rolling bending machine are as follows

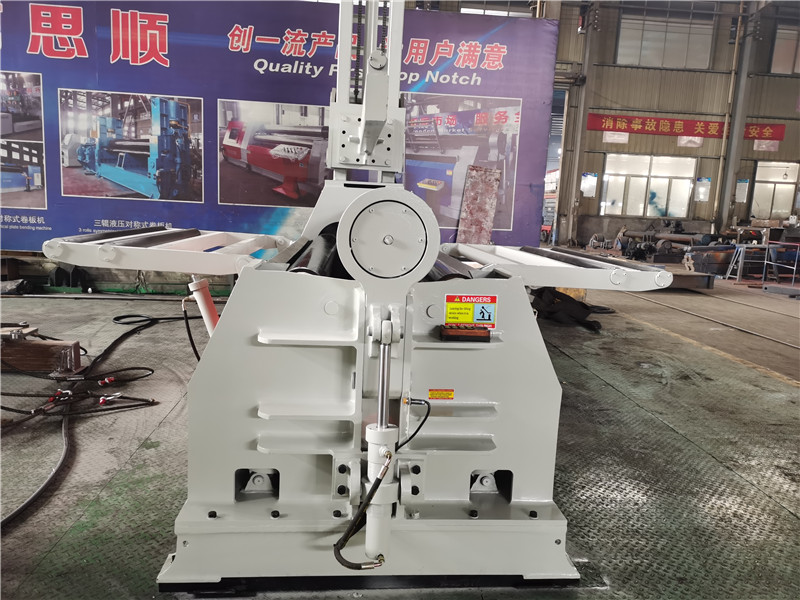

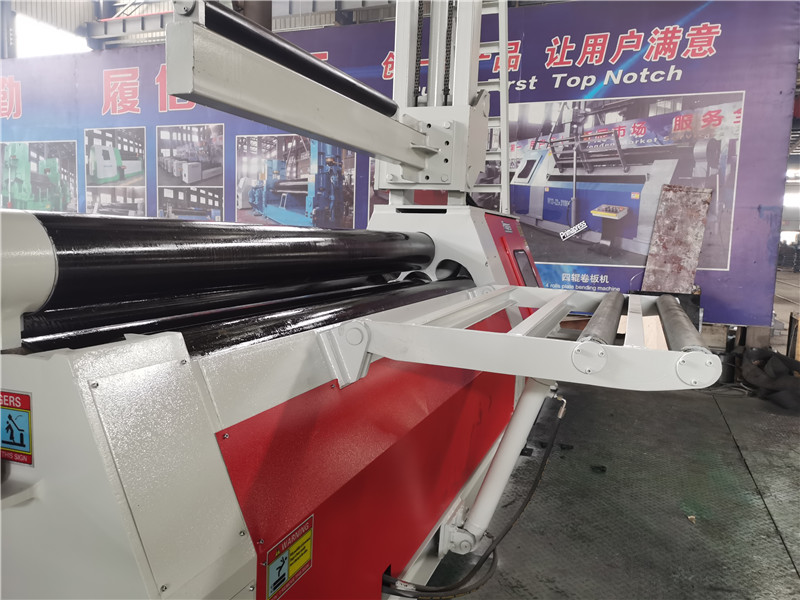

The plate bending machine is a general equipment for bending metal sheets into cylindrical, arc or other shaped workpieces. The upper roller is the driving roller, the lower roller and the side roller are driven rollers, the position of the upper roller is fixed, the lower and side rollers can move up and down, the upper roller is driven by a hydraulic motor, and the rotation of the lower and side rollers is driven by the steel plate and The friction between the rollers is driven. Both the lower roller and the side roller are pushed by the oil cylinders at both ends to realize the lifting movement. The overturning and reset of the bearing body on the front side of the upper roller is performed by the overturning oil cylinder, and the bearing bodies and oil cylinders of each roller are installed in the frames at the left and right ends. The left and right frames are the main body of the four-roller plate rolling machine, which adopts a welded structure and is installed on the overall base. The pushing device is the finished product that is rolled. After the overturning cylinder is turned in place, the workpiece is pushed out of the machine; all operations of the machine are carried out on the operating table.

The precautions for the safe operation of the metal sheet plate CNC rolling bending machine are as follows:

1: The operator should understand the structure and performance of the machine, be familiar with the operation method of the control system and the bending process of the workpiece, and strictly abide by the operation matters.

2: Before driving and parking, all buttons of the electronic control system should be placed in their original positions.

3: During use, the oil supply of each lubricating point should be checked frequently, and the reducer should maintain the specified oil level.

4: During the operation, if irregular noise, impact and swing are found, it should be stopped in time for maintenance.

5: During the use process, the transmission mechanism and connecting parts should be checked frequently to keep it free from looseness and damage.

6: It is not allowed to roll unleveled steel plates directly on the machine.

7: The plate should be perpendicular to the centerline of the roller when it enters the formal bending.

8: During the bending process, the plate should move with the roller, and no slippage is allowed.

9: When bending the conical cylinder workpiece, the small end of the conical cylinder should be at the end of the overturned bearing.

10: During the rolling process, the lifting of the upper roller, the disengagement of the overturn bearing and the lifting of the upper shaft should be carried out only after the active drive stops.

11: The unloading work is to loosen the overturn bearing after the machine is stopped, then disengage it and lay it flat, press the lifting button of the upper roller to raise one end of the upper roller (3 degrees), take out the workpiece, and press the upper roller. Roll down button, make the upper roll flat, close the flip bearing, and complete a working cycle.

How to operate to prolong the service life of the rolling machine?

For the metal sheet plate CNC rolling bending machine equipment, its service life is composed of two parts, one part is the careful operation in use, and the other part is the maintenance during daily work. A lot of maintenance work has been introduced before, so how to operate it to prolong the service life of the metal plate plate CNC rolling bending machine?

Before the metal plate plate CNC rolling bending machine is used, it is necessary to start the test to check whether there is any problem with the equipment. Then, check the oil level displayed by the oil mark on the side of the transmission box. If the oil level is lower than the oil line, it needs to be removed from the box cover. Fill the tank with lubricating oil up to the limit. Therefore, after the inspection, the equipment is placed smoothly, and the four wheels are evenly stressed, and the production activities can be carried out.

The following are some detailed operations, which can also help extend the life of the sheet metal plate CNC rolling bending machine:

- When the pressure roller is feeding, first loosen the upper nut, and after reaching the scale, tighten the round nut to fix it. When the passive pressure roller enters, the workpiece should be withdrawn.

- After using for a certain period of time, clean up the residue left by pressing the workpiece in time, so as not to affect the normal use of the metal sheet plate CNC rolling bending machine.

- After using for a period of time, check the oil level displayed by the oil mark on the side of the transmission oil tank, and add it in time when the oil level is too low.

- In use, it should be noted that the operation should not exceed the load according to the working range.