Maintenance method of hydraulic sheet metal double-roller bending machine 2 rolls rolling machine

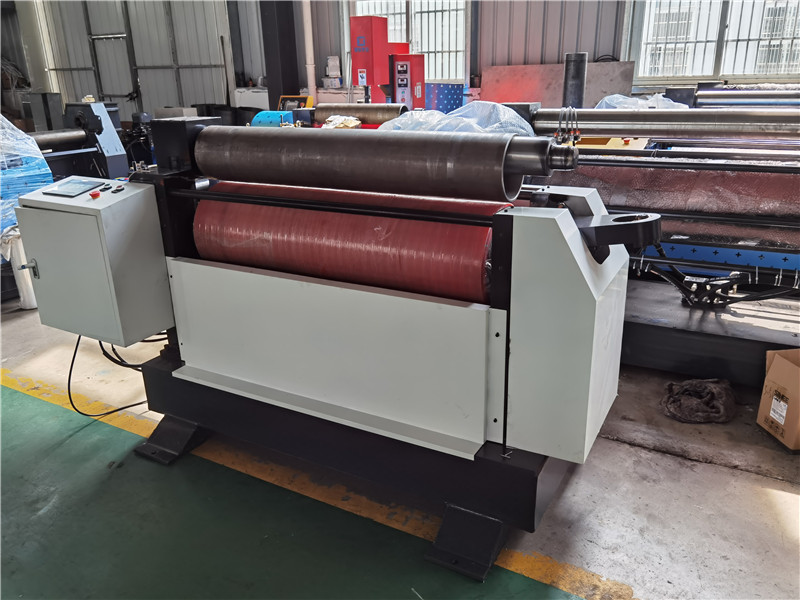

The hydraulic sheet metal double-roller bending machine is a sheet metal double-roller-to-roller type rolling equipment with simple structure, one-time forming and easy operation.

It is a rolling equipment suitable for small-diameter workpieces of various metal sheets. The steel plate is pressed between the driven roller (steel roller) and the driving roller (rubber roller),

and the elastic layer of the roller becomes a concave shape, which promotes the bending of the steel plate and becomes a roller shape.

The structure of the hydraulic sheet metal double-roller bending machine is a sheet metal double-roll symmetrical type. The upper roller moves vertically relative to the position in the center of the two rollers, and is obtained by the working oil in the hydraulic cylinder acting on the piston, as a hydraulic transmission The two rollers of the roller rotate, and the output gear of the reducer and the lower roller teeth are mixed to apply torque to the roller plate. The machine tool of the bending machine is compact and easy to operate and maintain.

The hydraulic sheet metal double-roller bending machine does not need to speed up the pre-bending process, and can be processed and formed by winding the sheet at one time. It has the characteristics of high product accuracy, no damage on the surface, no residual straight edges, and high production efficiency. Operators should also pay attention to the maintenance of the rolling machine, because its production quality and life are also related to the customer’s usual maintenance. The following introduces some small maintenance methods:

(1) According to the mechanical lubrication mode and the need for manual lubrication. (2) After the power is turned on, carry out the up and down movement of the lower roller in the positive and negative directions and the upper roller to check whether there is any abnormal adhesion phenomenon in each movement. (3) If irregular noise or impact is found during operation, please stop the inspection immediately. (4) Operate strictly in accordance with the processing procedures and operating methods of the coiling machine. When the upper roll is lifted to the limit position, full attention must be paid to the safe operation of the equipment.

(5) During the operation, all personnel should coordinate with each other, obey the instructions of the operators, and it is forbidden to start the machine without communication.

(6) After the main drive stops, the upper roller can be raised and lowered, the reverse bearing can be overturned and reset, and the upper roller can be warped. (7) When carrying out the plate rolling operation of the large plate rolling machine, please pay sufficient attention not to be pressed by the steel plate and be rolled together with the steel plate. (8) When lifting the steel plate and spool by walking, please be careful not to collide with the machine.

(9) The maintenance of the coiling machine should be based on the requirements of the instructions. Overload and incorrect use are not conducive to the maintenance of the coiling machine.

After powering on the coiling machine, please strictly abide by the processing steps and operation methods of the coiling machine. After the coiling machine is finished, the workplace should be cleaned up, the corresponding maintenance operations should be carried out, and the power supply of the equipment should be cut off in time to prevent accidents.

The above is the introduction to the maintenance method of the hydraulic sheet metal double-roller bending machine.