Maintenance method of CNC press brake bending machine and introduction of product parameters

What is a metal plate cnc press brake bending machine?

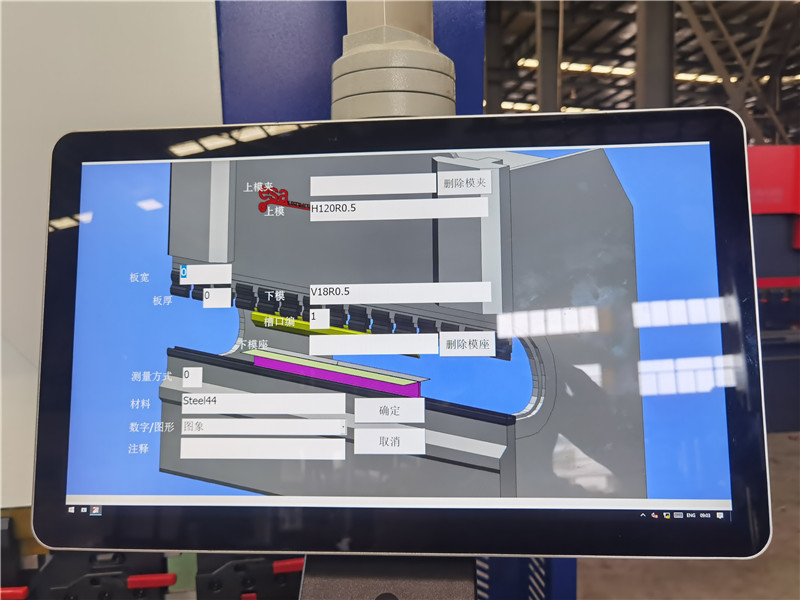

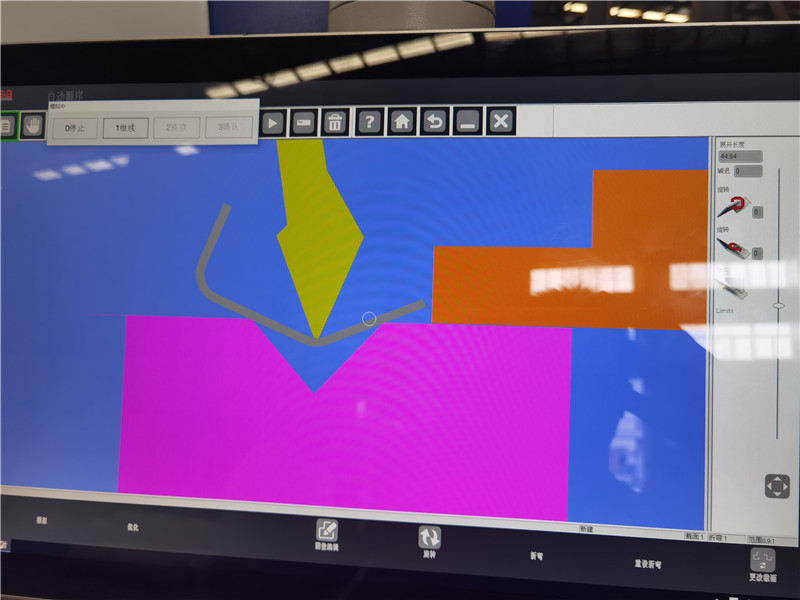

The metal plate cnc press brake bending machine is an electro-hydraulic synchronous double-cylinder up-moving metal plate cnc press brake bending machine. Its bending principle is basically the same as the angle forming principle of ordinary bending machines. The forming of the bending angle (free bending method) is controlled by the depth (bending depth) of the upper die pressing the sheet in the lower die, or the workpiece is pressed. A workpiece with the same angle (shape) as the mold (bottom bending method).

So what is a metal plate cnc press brake bending machine? The numerical control system controls the electro-hydraulic proportional directional valve, and the digital control mode of the bending depth is fully closed through the feedback of the grating ruler. The numerical control system controls the ball screw driven by the AC digital servo system, and forms a semi-closed-loop digital control method for the positioning position of the back gauge through the disc-type photoelectric encoder. Therefore, it can be simply summarized as: a bending machine controlled by a numerical control system for the automatic compensation of the back gauge positioning system, the bending depth of the slider and the deformation of the table.

Conventional bending sequence of metal plate cnc press brake bending machine:

Short side first and then long side: Generally speaking, when all four sides are bent, folding the short side first and then the long side is conducive to the processing of the workpiece and the assembly of the bending die;

Periphery first and then middle: under normal circumstances, it is generally folded from the periphery of the workpiece to the center of the workpiece;

Partial first and then whole: If there are some structures inside or outside the workpiece that are different from other bending structures, generally these structures are bent first and then other parts are bent;

Consider the interference situation and arrange the bending sequence reasonably: the bending sequence is not static, and the processing sequence should be adjusted appropriately according to the shape of the bending or obstacles on the workpiece.

The operation of the metal plate cnc press brake bending machine should be in accordance with the operation manual, safety operation rules and operation instructions of the bending machine, and various protective work should be done to ensure personal safety and equipment safety. , Do not reach out from the knife edge of the bending machine to adjust the rear gear; you should go directly to the back of the equipment to adjust; when processing parts, the human body should be outside the range of motion of the parts to avoid the parts from scratching the human body; the human body should stand firm during operation, The balance of the body cannot be affected by the movement of the workpiece; the removed tool cannot be placed on the bending machine, nor can it lean on the bending, so as to avoid the tool falling and hurting the human body.

In recent years, with the continuous increase of labor costs, many companies have chosen to purchase CNC press brake bending machines to replace labor in order to save costs, but because of the lack of understanding of its maintenance methods, it often leads to shutdowns, so how should CNC press brake bending machines be repaired? Woolen cloth? Let’s take a look together. The following is an introduction to “the maintenance method of CNC press brake bending machine and the introduction of product parameters”.

【How to overhaul the CNC press brake bending machine】

CNC press brake bending machines always wear out in a certain working environment, and PLC is no exception. Although the design of the PLC has reduced maintenance and failures to a small extent, if regular maintenance and overhaul can be carried out on the PLC, it can be strived to keep it always working and in the state, and at the same time, the system failure can be greatly reduced.

- Maintenance and repair

The main contents of maintenance and overhaul include checking whether the power supply voltage is normal, whether the surrounding environment meets the installation requirements, whether the voltage of the input and output terminals is normal, whether the backup battery is regularly replaced, whether the PLC units are firmly installed, and whether the junction box terminals are in good condition, etc.

- Backup battery replacement

The backup battery of the PLC has a certain lifespan. For example: operating at an ambient temperature of 25°C, the battery life is about 6 years. When the backup battery voltage is low, the indicator “ERRLED” lights up. This is, the battery must be replaced within 1 month.

When replacing the battery, first charge the PLC for more than 1 minute, and then replace it within 3 minutes. The specific operation steps are as follows.

① Cut off the power supply of the CNC press brake bending machine.

②Open the storage unit cover.

③ Unplug the backup battery and pull it up until the battery cover is pulled open.

④Pull out the lead and remove the battery.

⑤ Install a new battery and connect it to the PLC socket.

⑥Cover the battery cover and storage unit cover.

⑦Turn on the PLC power.