Main Components and Structure Description of sheet metal CNC press brake Bending Machine Tool

this is the main parts of the cnc press brake bending machine:

| Name | Origin |

| Asynchronous motor | Siemens, Germany |

| Controller | Delem DA53T,DA66T , DA58T Holland |

| Transformer | SCHNEIDER |

| AC contactor | SCHNEIDER |

| Circuit Breakers | SCHNEIDER |

| Servo motor | Estun |

| Gear pump | Siemens pump |

| Sealing parts | Valqua ,Japan |

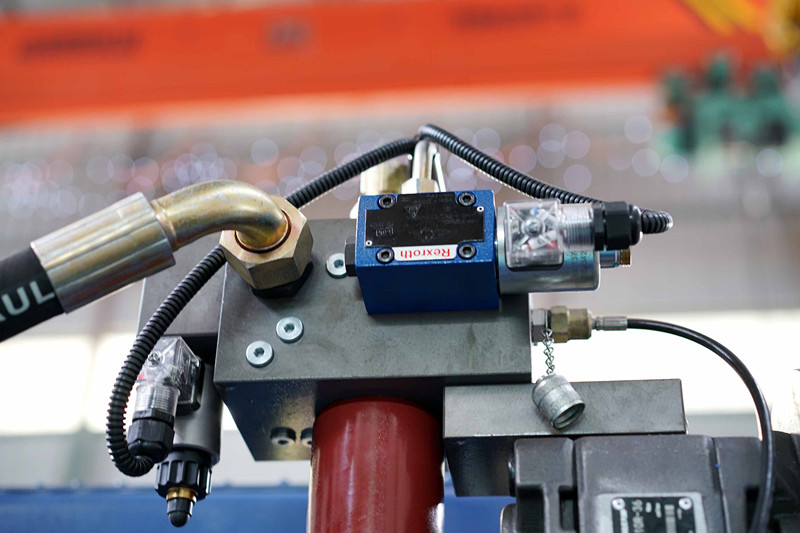

| Hydraulic Integrated Systems | Bosch, Germany, |

| Quick release | China Shanghai |

Main parts and structure description of CNC bending machine tool:

- Slider: Hydraulic transmission is adopted. Slider is composed of slipper, cylinder and fine-tuning structure of mechanical block.

- The left and right cylinders are fixed on the frame, and the piston (rod) drives the slider up and down by hydraulic pressure.

- The mechanical block is controlled and adjusted by the numerical control system.

- Workbench part: It is operated by button box, so that the motor drives the shield to move forward and backward, and the distance of movement

- is controlled by numerical control system. Its minimum reading is 0.01 mm (both front and rear positions have the limit of stroke switch).

- Synchronization system: The machine is composed of torsion shaft, swing arm and joint bearing. It has simple structure, stable and

- reliable performance and high synchronization accuracy. The mechanical block is regulated by the motor, and the numerical control system controls the value.

- Material retaining mechanism: Material retaining is driven by motor, and two screw rods are moved synchronously by chain operation.

- The size of material retaining is controlled by numerical control system. The combination of laser processing system and computer numerical control

- technology can form efficient automatic processing equipment, which opens up broad prospects for high quality, high efficiency and

- low cost processing and production. Laser engraving machine is a new type of laser peripheral processing equipment which combines

- laser technology and computer technology. Laser engraving machine adopts high-performance laser and numerical control technology,

- through self-developed optical system, control system and computer software, realizes three-dimensional dynamic precision laser engraving

- in crystal and glass. It solves the problems of slow engraving speed, unstable system operation, loss of laser point, incomplete function of image

- and word processing software, using computer interface control card and laser explosion point. Equilibrium, imperfect automatic control device,

- low cost performance of equipment and other issues. It improves the efficiency, accuracy, maintainability, versatility and security of the system.

- It is inevitable that the inner sculptures of crystal glass will become richer in color. Using the optical principle that the inner carving part of crystal glass crafts

- has strong reflection and refraction to light, while the blank part has better permeability to light, the micro-control circuit controls several kinds of color lights

- according to the principle of three-tone palette, mixes colors on the “inner carving” image, and changes many kinds of gorgeous colors,

- so that the original white inner carving image is presented. It shows a colorful and brilliant effect.