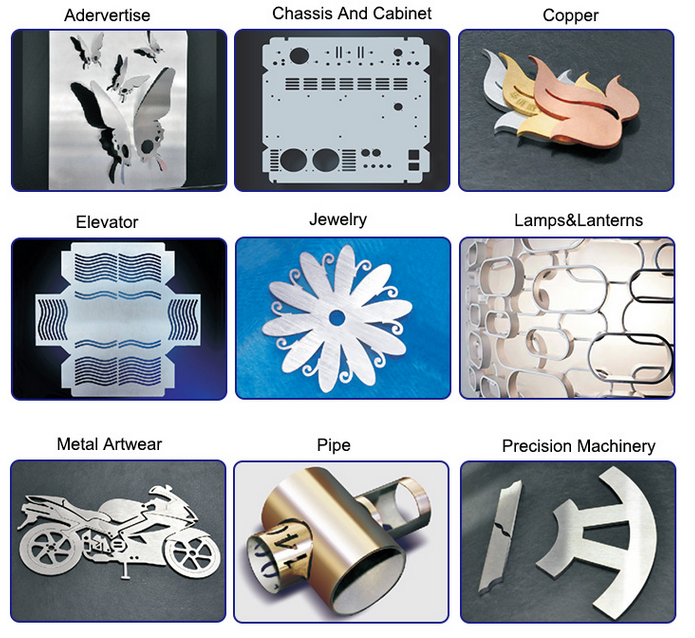

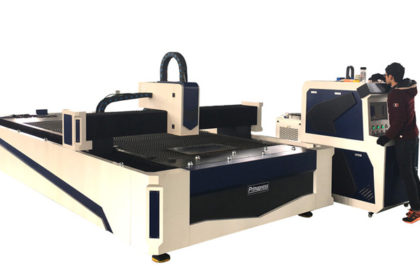

Laser cutting machines commonly used in light industry, heavy industry and other industries, currently available conventional cutting machine, plasma cutting machine, flame cutting machines, laser cutting machine. In the metal cutting machine tools are currently in the traditional cutting machine, laser cutting machine. Take, individually and laser cutting machine is mainly metal sheet metal processing, metal cutting, lower metal material, chassis, chassis cutting, sanitary ware, kitchen utensils, instrument panel appearance, elevator panels, etc. industries.

Currently laser cutting machine is divided into small and medium-power and high-power cutting machine. Small power cutter individual in 1000W or less, the price is definitely cheap, cut metal thickness of the individual will not exceed 10 thick. The high-power laser cutting machine 1000W individual in even more than a few kilowatts. Cutting thicker, the price is relatively high, only a few large manufacturers for example, car parts processing apply.

1, carbon steel plate cutting. Modern laser cutting system can cut carbon steel plate close to the maximum thickness of 20mm, for thin kerf can narrow to about 0.1mm. Laser cutting mild steel heat affected zone is extremely small, and cut every flat, smooth, vertical well. High-carbon steel, laser cutting edge quality is better than mild steel, but the larger the heat affected zone. Di can be laser series laser metal cutting machine maximum depth of 10mm.

2, stainless steel cutting. Laser cutting relatively easy to cut stainless steel sheet. High-power YAG laser cut stainless steel cutting system has a maximum thickness of up to 4mm. We develop low-power YAG laser cutting system cut stainless steel up to a thickness of 4mm.

3, steel plate cutting. Most steel can be cut with a laser, a good edge quality. But tungsten tool steel and high thermal die steel, laser ablation will sticky residue when cutting.

4, and aluminum alloy sheet cutting. Aluminum belong to melt cutting cutting, to be his assistant, gas cutting area of the melt blown off, it can achieve better quality section. Cutting present a maximum thickness of aluminum 1.5mm. 5, other metal materials cutting. Copper suitable laser cutting, cutting very thin. Titanium and titanium alloys, nickel alloys are available most of the laser cutting. Non-metallic materials. Di CO2 laser energy CO2 laser cutting machine marking cutting engraving machine series utility carved wood, paper, rubber, leather, acrylic, plastic, cloth fiber composite materials, carved horns, color plates, copper paint. The minimum slit 0.1mm, individual metal cutting machine cutting thickness than four hours to add individual gas. At present, Di laser metal cutting machine can take in air cutting thickness can reach 8 thick. Steel cut thickness of about 8mm, less dross, the thickness can reach 10mm cutting, cutting the thickest in YAG medium power industry. Within cut 6mm stainless steel, carbon steel less than 8mm are able to cut the use of air effectively frugal use of capital, the consequences of laser cutting machine is also very good.