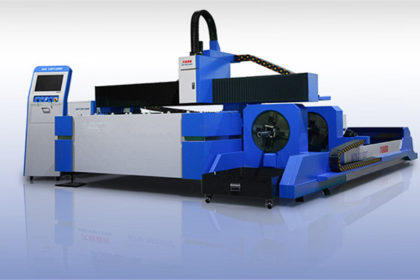

High-tech laser cutting machine is developed in recent decades, as opposed to conventional cut process for cutting higher precision, lower roughness and higher material utilization and production efficiency and other characteristics, in particular, in the field of fine cutting, laser cutting with a conventional cutting incomparable advantages. Laser cutting is to focus the energy to a small space, the use of high energy density of non-contact, high-speed, high-precision cutting method.

Laser vaporization

High energy density laser beam heats a workpiece, the temperature rises rapidly, in a very short time to reach the boiling point of the material, the material begins to vaporize to form a vapor.

These vapor discharge rate is large, the vapor ejected at the same time, the material cut.

Heat of vaporization material is generally large, so the laser vaporization requires a lot of power and power density when cutting.

Laser cutting machine used for cutting thin metal vaporization materials and non-metallic materials (such as paper, cloth, wood, plastics and rubber, etc.) cutting.