Knowledge of the use and maintenance of metal sheet four-roller rolling bending machine

- According to the regulations in the machine lubrication diagram, add oil to each oil cup lubrication and manual lubrication points as required.

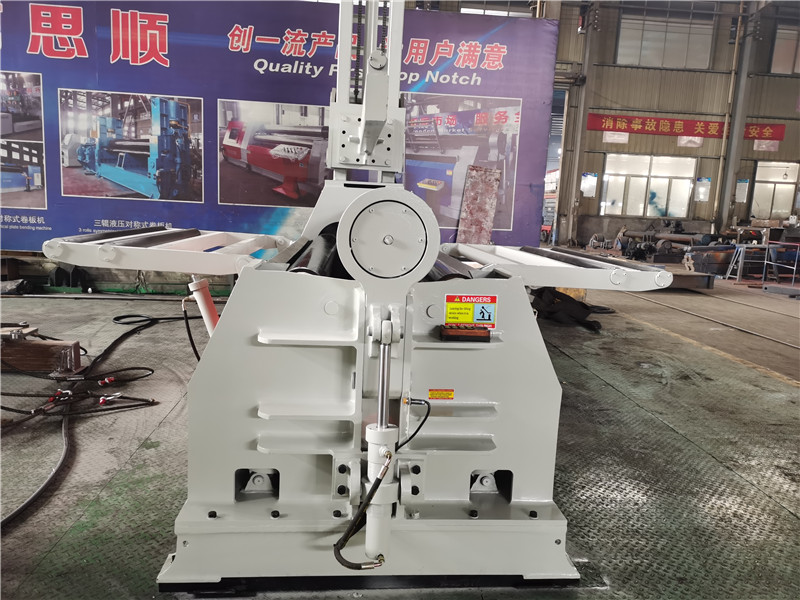

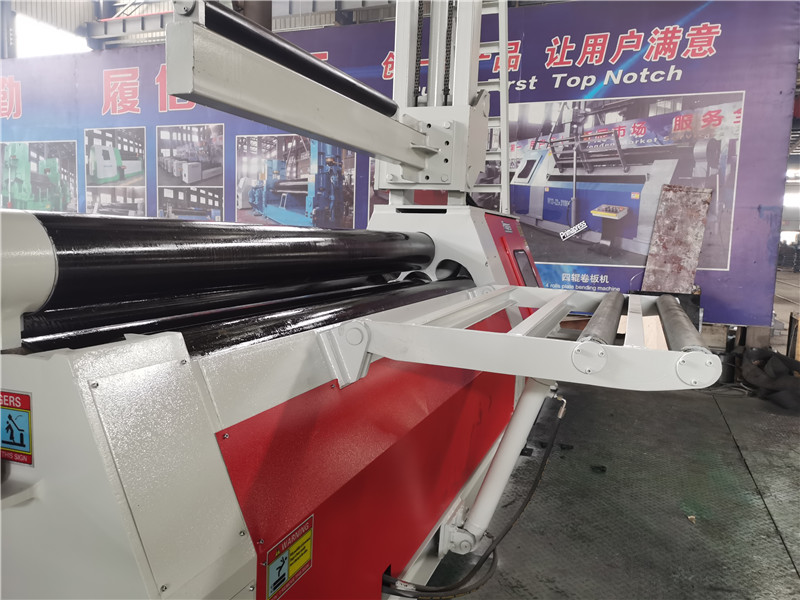

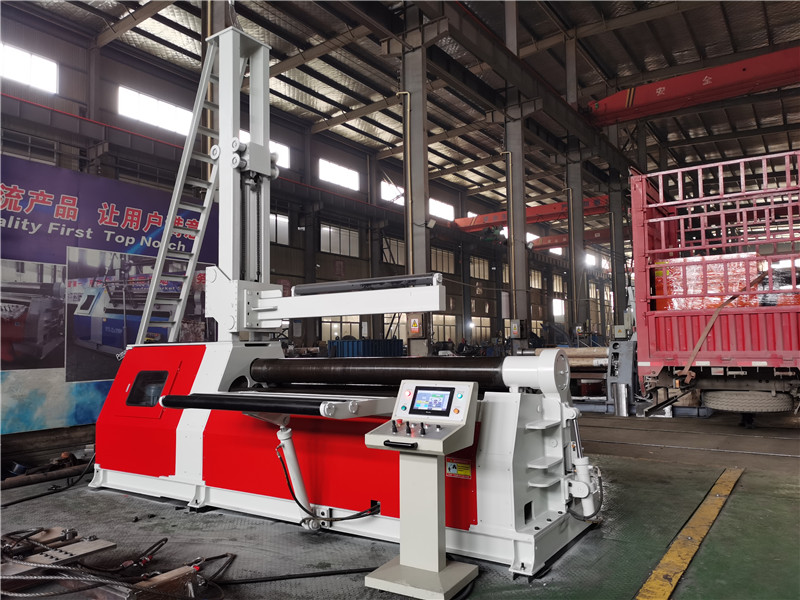

- Roll the plate according to the parameters specified by the four-roll plate rolling bending machine. The thickness of the plate is 20mm, the maximum length is 2500mm, and the yield limit of the plate material is less than 250Mpa.

- After the power is turned on, carry out the forward and reverse directions of the lower roller and the lifting and lowering of the upper roller, and check whether there is any abnormal stuck phenomenon in each movement.

- Operate in strict accordance with the rolling bending process procedures and operation methods. When the upper roller is lifted to the limit position, great attention should be paid to the safe operation of the equipment.

- When the main drive stops, the upper roller can be lifted and lowered, the overturned bearing can be tilted and reset, and the upper roller can be lifted.

- During operation, if any abnormal phenomena such as irregular noise and impact are found, the machine should be stopped immediately for inspection.

- During the operation, all personnel should coordinate with each other, obey the command of the person in charge of the coil, and it is forbidden to start the machine without a password.

- When rolling bending the plate, pay great attention to the fact that the hand is pressed by the steel plate and rolled in together with the steel plate.

- Be careful not to collide with the machine when lifting the steel plate or reel with a crane.

After the coiling is finished, make sure that all materials are finished and the site is cleared, and the maintenance of the equipment is done well, and the power is turned off in time.

Flange forming effect is good, high efficiency! high speed! Can be rolled into a spring shape! Eliminate the previous manual cutting, welding, forging and other processes!

installation, use, maintenance

- Installed on a hard foundation, the equipment remains stable.

- Strictly abide by the rules and regulations and safety operation procedures

- The operator should understand and master the structure and working principle of the equipment and maintenance check points.

- Master the method and sequence of starting and stopping (operate according to the instruction manual of the electromagnetic speed regulating motor).

- The reducer should be lubricated before starting.

- If the equipment needs to be reversed when it is running, the speed control switch should be reset first, and then stop for 1 minute before starting the machine.

- When the driven wheel feeds, the fastening bolts should be loosened first. After the feed reaches the scale, the round nut should be tightened and fixed; the bolts (4-M30) on both sides of the driven wheel should be tightened and fixed. Each time the passive wheel feeds, the workpiece needs to be completely withdrawn before feeding.

- In the process of use, the debris in the pressure roller groove and the surface of the worktable should be cleaned up in time.

- The power supply of the machine is three-phase four-wire.

Safety operation rules of rolling bending machine

Roller safety operation rules

- The operator must be familiar with the functions of all switches and buttons of this equipment. Before starting the machine, all adjusting screws and control switches must be checked to ensure that they function properly.

- Operators must tie clothes and cuffs tightly, and it is strictly forbidden to tie aprons or noodles; women with long hair should curl their hair and wear a hat when working to prevent safety accidents from being caught.

- Before starting the equipment, add appropriate amount of lubricating grease to each transmission and sliding surface, and then proceed to the next step after the equipment runs normally, flexibly and reliably. 4. Obstacles in the front and back of the equipment must be cleared before starting the machine, and no one is allowed to stand in front of the machine.

- Adjust the position of the roller according to the diameter of the rolling bending circle. Use scraps to debug before operation, and do not directly take the workpiece for debugging.

- During operation, hands and other parts of the body should not be more than 20CM close to the roller. Non-operators are strictly prohibited from staying in front of the equipment.

- If any abnormality is found during the operation, it should be stopped immediately for inspection, and the operation can be continued after the fault is eliminated.

- The processed workpieces should not be placed directly on the ground, but should be placed on the floor plate or on the material cart, stacked neatly, and should not be stacked too high and obstruct the passage. 9. After the work is over, remove the oil and sundries on the machine and mold, maintain the equipment, and clean the surrounding environment.