Introduction to CNC plate metal press brake bending machinesoperation tutorial

How to learn to use a CNC bending machine? How to use a CNC bending machine? Regarding the introductory operation tutorial for CNC bending machines, I believe many users have already read many versions, including detailed explanations in pictures and text, as well as video operations. The content is very detailed, but after reading it, people may find that the content is too standard and official, making it difficult to understand. Therefore, many users want to read some easy to understand tutorials. Below, we will share with you how to easily use a bending machine, and you will know at a glance.

Introduction to CNC plate metal press brake bending machinesoperation

Introduction to CNC plate metal press brake bending machinesoperation tutorial

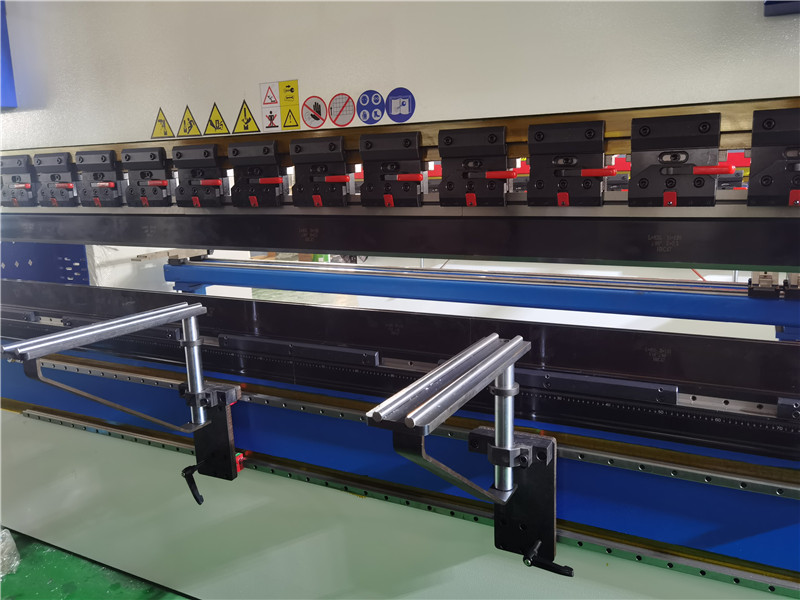

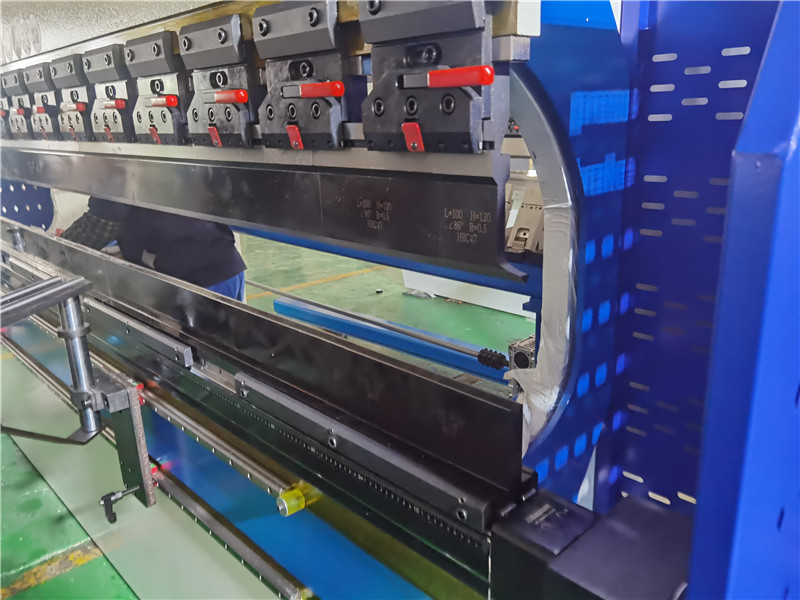

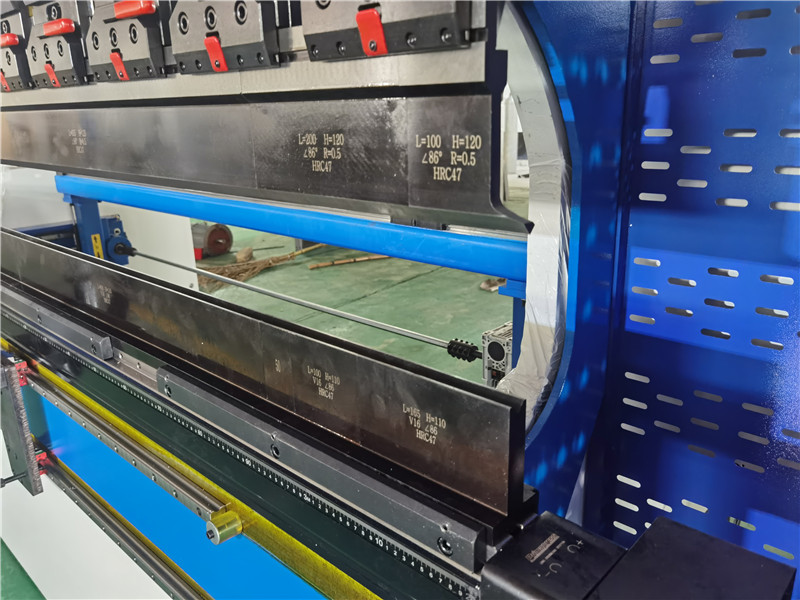

Firstly, before operating the CNC bending machine, we need to understand the equipment components. The overall structure of the CNC plate metal press brake bending machinesis mainly divided into three parts: the bracket, clamping plate, and workbench, each of which is indispensable. During use, it is necessary to ensure that all three parts have no problems before continuing the operation. The main principle of using a CNC plate metal press brake bending machinesis that when the wire and coil are energized, a gravitational force is generated on the pressing plate. After the gravitational force is generated, the clamping between the pressing plate and the base can be achieved, thereby achieving the bending of the sheet metal. The specific operation tutorial is as follows:

- Power on preparation

To use a CNC bending machine, the first thing to do is to power on the bending machine first. We need to turn on the start switch of the power supply on the control panel of the bending machine, and then start the oil pump. If we hear the sound of the oil pump rotating, it means that the bending machine is not a problem. At this time, we do not need to do any work, let the oil pump idle for about 80 seconds;

- Stroke adjustment test

In the second step, we need to test the machine and adjust the stroke. The specific operation is to keep the thickness of one sheet when the upper mold descends to the bottom position. This step is an important step to ensure that the bending machine can work normally without affecting the service cycle of the bending machine, and must not be ignored;

- Select notch

The thickness of the bending and the size of the groove are selected in this step, and the program is set according to actual standards. Within the industry standard range, the size of the groove is determined based on the thickness of the sheet metal. Normally, a slot size of 8 times the width of the sheet metal is selected. For example, when bending a 3mm sheet metal, a 24mm groove needs to be selected, and the calculation is very simple;

- Adjusting the blocking material

This step is mainly to confirm the position and level of standardization of the rear stopper to ensure its normal operation;

- Press the switch to operate

After the above preparation and testing work is completed, we can press the switch to start bending the sheet metal. It should be noted that the pedal of the bending machine can be released at any time. The principle for releasing and stepping is to release and stop the stepping work, which is very simple.

The above is a very simple and practical introduction to CNC plate metal press brake bending machinesoperation tutorial content to share with everyone, for those in need to reference. Objectively speaking, the bending machine, due to its CNC operation, can directly bend the product, and the appearance of the bent product is flawless and of good quality. For enterprises, it not only improves production quality, but also plays a huge role in improving production efficiency. This is reflected in reducing labor costs and shortening the production cycle of bent products. Finally, I would like to remind everyone that it is necessary to inspect and maintain the bending machine before and after use. This is also a very important part of work, as it can ensure and extend the lifespan of the CNC bending machine.