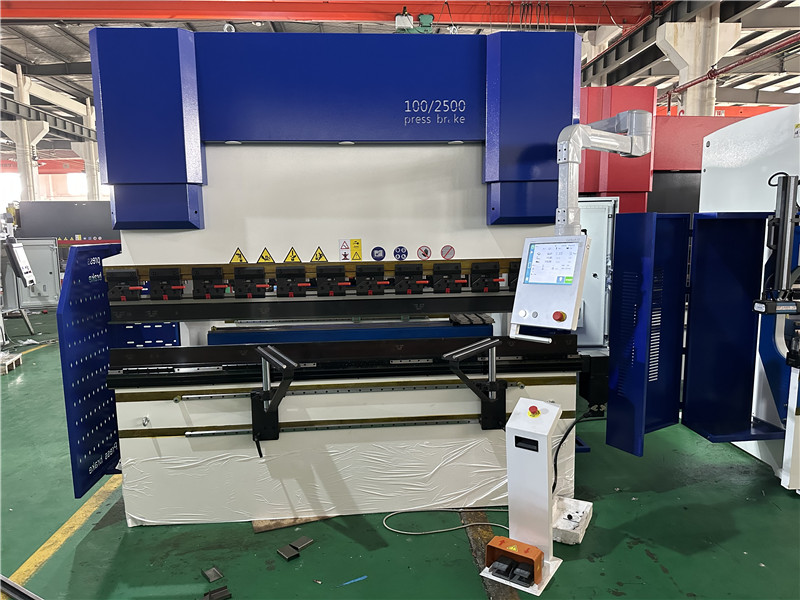

Introduction of electro-hydraulic servo synchronous CNC Press brake bending machine

Electro hydraulic servo synchronous CNC Press brake bending machine is to install optical (magnetic) grating ruler on the slider and body. The CNC system of Press brake can analyze the synchronization of both sides of the slider through the real-time feedback information of optical (magnetic) grating ruler. If there is an error, the CNC system will adjust it through a proportional valve to synchronize the stroke on both sides of the slider. Numerical control system, hydraulic control valve group and grating ruler together constitute the feedback closed-loop control of electro-hydraulic synchronous Press brake. In short, electro-hydraulic synchronous CNC Press brake bending machine is a sheet metal processing equipment with more optimized design principles, more complete functions and guaranteed accuracy and speed.

- Performance and structural characteristics of electro-hydraulic servo synchronous CNC Press brake bending machine

1.1 Performance of machine tools

1.1.1 Adopting a brand new rigid design and finite element optimization analysis, it has good stiffness and stability, minimizing the impact of bending deformation on the quality of the workpiece, and ensuring the machining accuracy of the workpiece.

1.1.2 The full closed loop electro-hydraulic servo synchronous control system imported from Bosch Rexroth, Germany, is used for feedback synchronization.

1.1.3 Adopting a new process design with a minimalist style, the appearance is simple and atmospheric. The machine tool is sandblasted for rust removal, and additionally sprayed with anti rust paint.

1.1.4 Speed: the electro-hydraulic servo synchronous Press brake can set and save each bending process through the computer, which can be operated continuously and effectively improve the speed of the bending steps, thus improving the work efficiency. When the slider moves down at the same time, the speed has both fast and slow down functions, and the transition between fast and slow is smooth, which can greatly improve production efficiency. Taking our 2.5m electro-hydraulic servo CNC Press brake bending machine as an example, the fast down speed can reach 300mm/s, the return speed is 200mm/s, and the working speed is 25mm/s.

1.2 Structural characteristics of machine tools

1.2.1 Overall welding of the entire steel plate, and the welding process, pre welding preparation, welding, welding correction, post welding heat treatment, weld quality inspection, weld seam repair and other technical requirements of all welding components shall comply with the provisions of the process documents; Match the welding material with the base metal; For large structural components, using a large annealing furnace for overall annealing has strong seismic performance;

1.2.2 Using a large tempering furnace to eliminate stress through vibration, with good stability and no deformation of the frame;

1.2.3 The rack is formed by precision floor boring machine or multi face machining center in one processing, ensuring the parallelism and verticality of each installation surface;

1.2.4 A “C” shaped plate mechanism is installed at the throat of the rack to directly detect the distance between the upper and lower molds, ensuring the accuracy of the workpiece.