Intelligent sheet metal manufacturing bending and cutting in the context of Industry 4.0?

manufacturing bending and cutting is the economic foundation of a country and has an important impact on people’s lives. Emerging technologies can change the rules of manufacturing bending and cutting modes, methods, concepts and even enterprises. Our next generation of Industry 4.0 promises to improve the flexibility of manufacturing bending and cutting while achieving mass customization, better quality and higher productivity. Therefore, it enables the company to meet the challenge of producing increasingly personalized products with shorter time to market and higher quality. Intelligent manufacturing bending and cutting plays an important role in Industry 4.0. Typical resources are transformed into intelligent objects so that they can perceive, act and act in an intelligent environment.

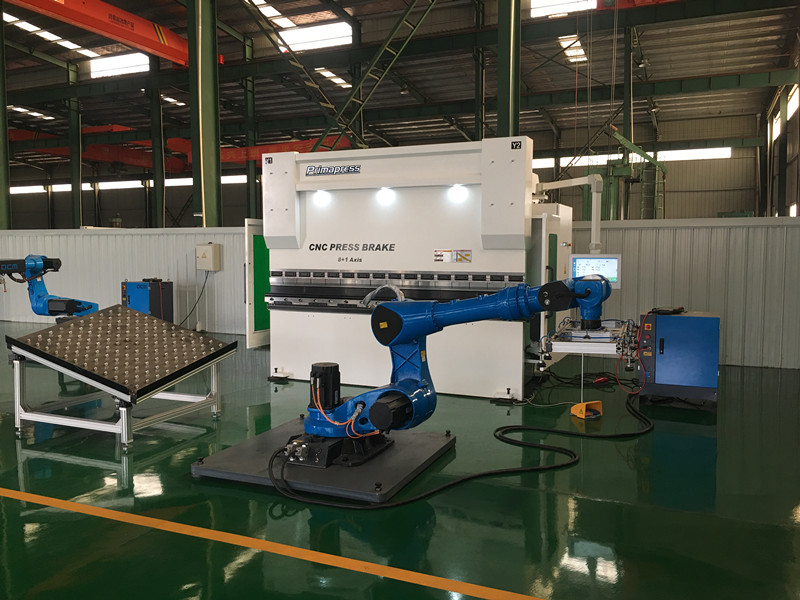

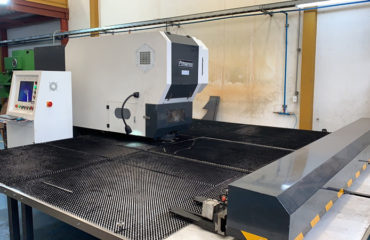

Sheet metal intelligent manufacturing bending and cutting

Industry 4.0 is a strategic initiative of Germany, which aims to create an intelligent factory and upgrade and transform manufacturing bending and cutting technology through network physical systems (CPSs), the Internet of Things (IoT) and cloud computing. In the era of Industry 4.0, manufacturing bending and cutting systems can monitor physical processes, create so-called “digital twins” (or “network twins”) of the physical world, and make intelligent decisions through real-time communication and cooperation with people, machines, sensors, etc. Industry 4.0 combines embedded production system technology with intelligent production processes, paving the way for a new technological era, which will fundamentally change the industrial value chain, production value chain and business model.

In the context of Industry 4.0, the manufacturing bending and cutting system has been updated to the level of intelligence. Intelligent manufacturing bending and cutting uses advanced information and manufacturing bending and cutting technology to realize flexible, intelligent and reconfigurable manufacturing bending and cutting processes to cope with the dynamic global market. It enables all physical processes and information flows to be used in the entire manufacturing bending and cutting supply chain, multiple industries, SMEs and large companies at the required time and place. Intelligent manufacturing bending and cutting requires some basic technologies to enable equipment or machines to change their behavior according to different situations and requirements based on past experience and learning ability. These technologies can communicate directly with the manufacturing bending and cutting system, so as to solve problems and make adaptive decisions in a timely manner. Some technologies also have artificial intelligence (AI), which allows manufacturing bending and cutting systems to learn from experience in order to ultimately achieve interconnected, intelligent and ubiquitous industrial practices.

Similar concepts to sheet metal intelligent manufacturing bending and cutting include cloud manufacturing bending and cutting and Internet of Things manufacturing bending and cutting. Intelligent manufacturing bending and cutting is a generalized manufacturing bending and cutting concept, which aims to make full use of advanced information and manufacturing bending and cutting technology to optimize production and product trading. It is a new manufacturing bending and cutting mode based on intelligent science and technology, which greatly improves the design, production, management and integration of typical products throughout their life cycle. Using various intelligent sensors, adaptive decision-making models, advanced materials, intelligent devices and data analysis can simplify the entire product life cycle. Improve production efficiency, product quality and service level. The competitiveness of manufacturing bending and cutting enterprises can be improved through their ability to face global market dynamics and fluctuations.

An implementation form of this concept is intelligent manufacturing bending and cutting system (IMS), which is considered as the next generation manufacturing bending and cutting system obtained by transforming traditional manufacturing bending and cutting system into intelligent system by adopting new models, new forms and new methods. In the era of Industry 4.0, IMS uses Service Oriented Architecture (SOA) through the Internet to provide end users with collaborative, customizable, flexible and reconfigurable services, thus realizing a highly。

rhdr