How to solve the problem of large bending angle error of CNC press brake bending machine?

The CNC press brake bending machine is mainly used for straight-line bending of plates. By using simple molds and process equipment, the metal plates can be pressed into a certain geometric shape, and can also be stretched, grooved, punched, corrugated and other processing. In actual production, it is mainly used to realize the bending of metal cabinets, boxes, U-shaped beams and rectangles of various geometric shapes. Its processing has the advantages of high straightness of bending edges and corners, no tooth marks, no peeling, no wrinkles, etc.

With the continuous development of NC press brake bending machine manufacturing technology, with its advantages of high positioning accuracy, convenience, flexible disturbance compensation, good product consistency, etc., but under limited circumstances, how to better use the press brake bending machine and give full play to its functions and advantages has become a concern and urgent problem to be solved by the press brake bending machine manufacturers.

How to solve the big bending angle error of CNC press brake bending machine?

- Check whether the compensation deflection of the compensation cylinder is large and the zero position cannot be completely restored;

- Check whether the quick clamp wedge is loose;

- Check whether the lower dead point of each bend changes;

- Check whether the bow wrench is installed in a standard way and whether the screw hole is blocked;

- The change of the plate itself (thickness, material, stress);

- Whether the grating ruler is loose;

7 , Inaccurate positioning accuracy: whether the zero offset value of the proportional valve is appropriate, and if the positioning cannot reach the bottom dead point, the return cannot be made.

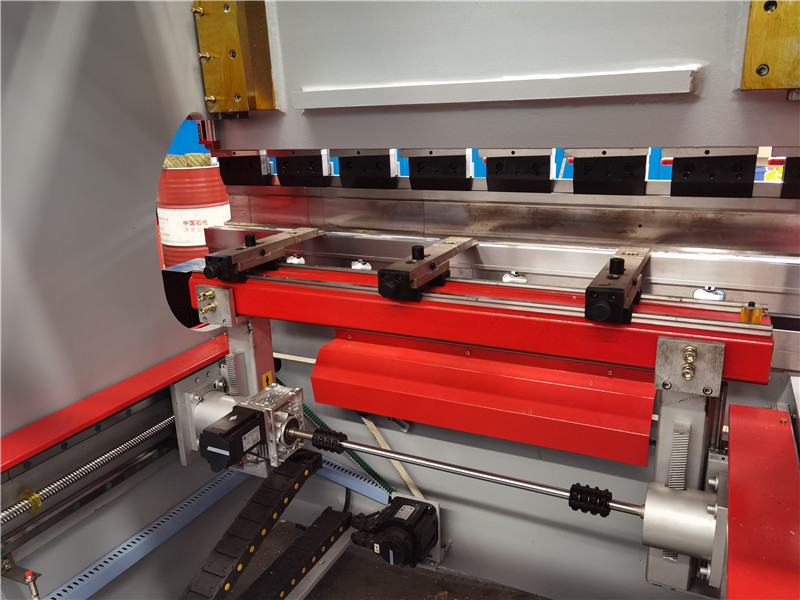

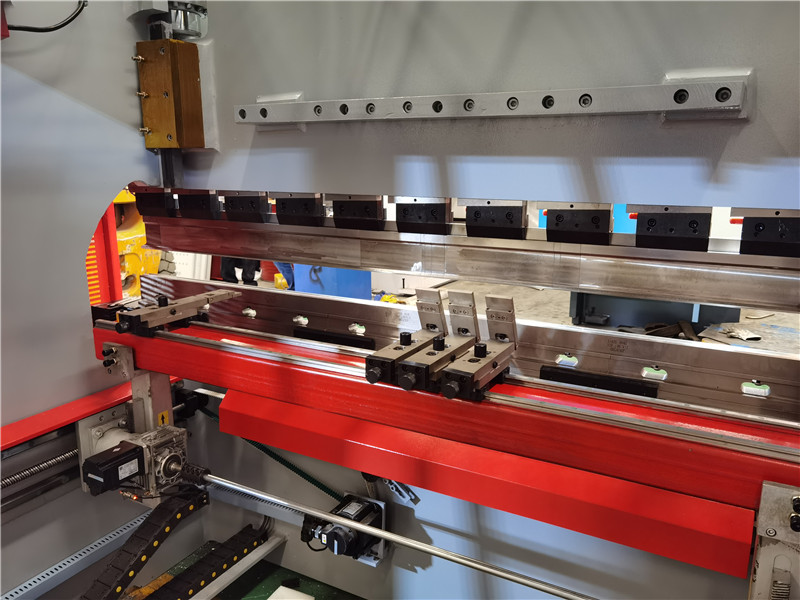

The use of CNC press brake bending machine mainly depends on the upper and lower molds. If the number of molds is small and the application is not flexible, the processing range of the machine tool will be greatly restricted. Therefore, under fixed conditions, how to give full play to the functions of existing molds to a large extent through optimization and local transformation is a problem that every machine tool user needs to think about.

The upper die grinds the tip. If the upper die is used for a long time, the tip wear will change irregularly, and the height of the die will change, so the bending accuracy cannot be guaranteed. The plate can be thickened by grinding, correcting the tip, and cooperating with a larger V-shaped groove, thus extending the service life of the die.

Changing the scrapped die to realize leveling is an example of how to solve the forming problem of pressing dead edges without compound bending die. The dead edge is a bending shape with two layers overlapped, which is usually used for strengthening. Generally, the plates with a thickness of more than 2.0mm rarely have dead edges. The pressed edge needs to be formed by a compound bending die, and it can only be formed by more than two processes. The common method is to use compound bending die.