How to reduce the wear of large CNC bending machines and increase the processing speed of CNC bending machines?

Equipment such as large-scale CNC bending machine is very troublesome once it is worn out. Some parts need to be replaced. Do you know how to reduce the degree of wear and tear of the bending machine? Mainly it still needs maintenance. In addition, it is necessary to know that the bending machine is correct How to use it, do you know how to use a large CNC bending machine correctly?

Measures to reduce the wear of large-scale CNC bending machines:

How to reduce the wear problem of large-scale CNC bending machines? To eliminate long-term machine hidden dangers and extend the service life of the machine, we need to do routine maintenance, mainly focusing on cleaning, tightening, adjustment and lubrication. The maintenance of large-scale CNC bending machine includes the following contents:

1, primary maintenance

Primary maintenance refers to the conversion of key tasks to the lubrication of the machine on the basis of routine maintenance. Then check and tighten the important parts to see if they have been cleaned.

2, secondary maintenance

The so-called secondary maintenance is: mainly focusing on inspection and adjustment, specifically checking the working conditions of the motor, clutch, transmission and other components of the large-scale CNC bending machine. When a fault is found, the machine must be stopped for necessary adjustments, and wait until it is normal. Turn on and use, so as to better guarantee the working performance of the machine.

3, three-level maintenance

For the three-level maintenance, its focus is on the work of detection, adjustment and failure. Moreover, it is necessary to diagnose and check the parts that affect the normal working performance of the machine. When necessary, the parts must be replaced or adjusted to ensure that the machine can be used normally.

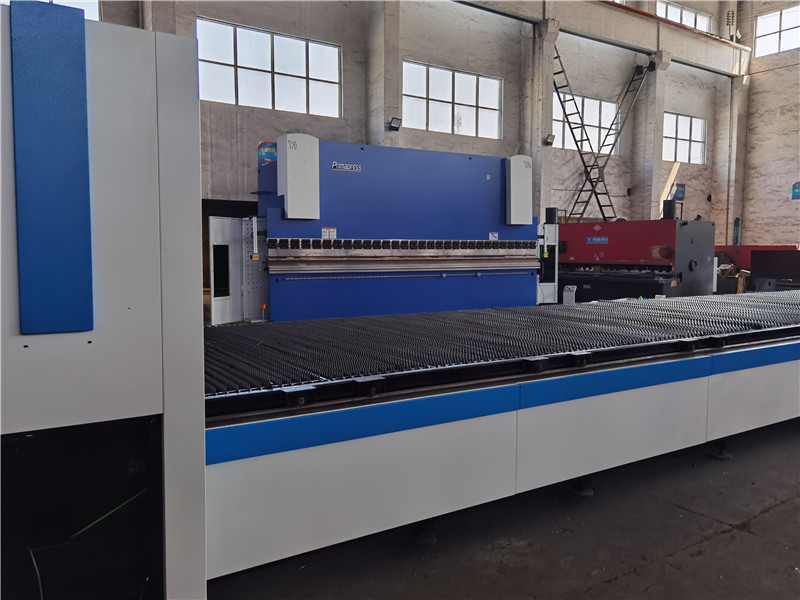

Large CNC bending machine

How to increase the processing speed of CNC bending machine?

Primapress In order to effectively increase the processing speed, the equipment is also equipped with many programming functions, so that the equipment can complete the processing operations of many kinds of workpieces at one time when it is running, and achieve higher production efficiency. The user can also adjust the equipment parameters according to the actual production requirements, so that the hydraulic system of the equipment is in a stable state, and the processing quality of the material meets the standard.

1. When installing and using metal materials, it is necessary to meet certain installation standards. In this way, the materials need to be processed according to operating requirements, and the accuracy of processing also has a great impact on the installation and use of materials.

The CNC bending machine is a kind of equipment product that is specifically responsible for completing the material bending operation. When using the CNC bending equipment, the user can set the parameters first, and then feed the material into the equipment to quickly complete the processing. Task.

2. When using a CNC bending machine, the system also comes with an angle compensation function. This function can avoid errors in the processing process and greatly improve the processing accuracy.

When using CNC bending equipment, the staff should strictly abide by the processing specifications to complete the operation. They should also wear designated clothing and protective tools to allow the processing operations to be completed under safe conditions.

- When installing and using the CNC bending machine, check whether the wiring of some equipment is firm, and whether the various devices can maintain a coordinated operation state. These checks should be done every day before using the equipment to ensure that the materials are accurate The processing effect.