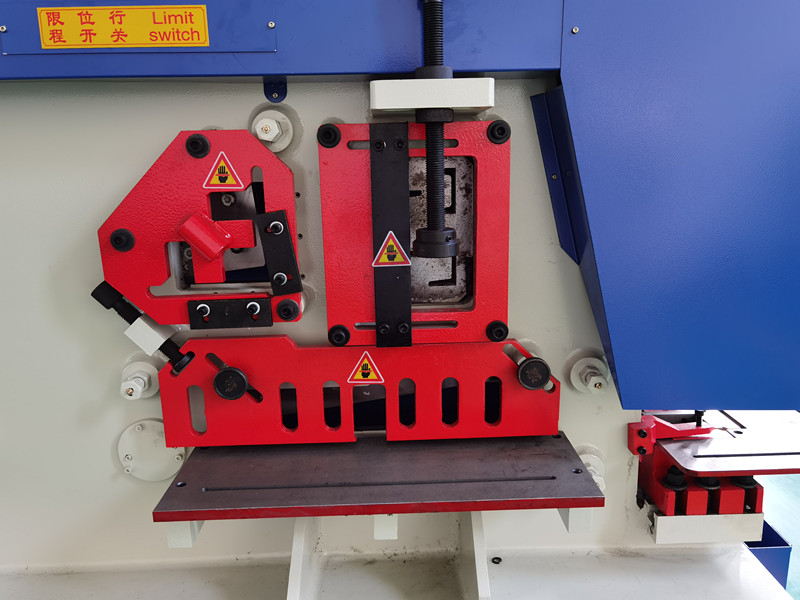

How to prevent problems when operating one China hydraulic ironworker machine

In the operation of the ironworker machine, if the splicing machine equipment and mold does not have safety protection equipment,

then the accident of hand injury will occur. Therefore, in the production of sheet metal processing and use of ironworker machine,

strengthening safety protection is an important way to prevent accidents. The choice of composite mode, continuous mode, multi-position

die can play a role in reducing the process to reduce the risk of operators.

In the stamping equipment and mold to set up safety protection equipment or choose the labor intensity of small, the use of convenient and

flexible craft things, but also under the conditions to complete the stamping operation safety of an effective way. Such as the selection of craft things,

mold shield, mechanical access equipment, double-button switches, mechanical hand-pulling, pusher and hand-dialing equipment, photoelectric active protection equipment. Stamping equipment protection equipment in many forms, according to the layout is divided into mechanical, button-type, photoelectric, induction and so on.

Mechanical protective equipment layout is brief, easy to make, but the work disturbance is larger, the operator sloth sourcing the use, the application is less.

Sheet metal processing cutting machine operation when the use of hand safety things can prevent due to the mold design is unreasonable and equipment

sudden problems caused by the incident. Common safety things are: elastic calipers, special calipers, magnetic suction cups, tweezers, pliers, hooks and so on.

The protective approach to the mold is included in the installation of protective plates (covers) around the mold and the mold layout is improved.

Such as reducing the mold risk area, expand ingestsafe space, set up mechanical materialing equipment, without affecting mold strength and product

quality, the original process of the original single-process mold delivery to improve, to improve safety.

Touch protection devices are used to control the movement of the slider using the touch rod, both regularly open and normally closed. This protection

equipment layout is brief, low production costs, convenient operation, workers can work in series of several sets of equipment together.

It is suitable for sepressurers with conflict clutches and modified rigid clutch presses.

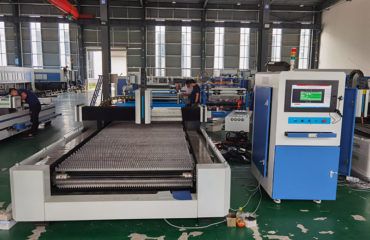

hydraulic combined punching&shearing machine can cut and punch all kinds of materials such as plate, square bar, angle,

round bar, channel and so on.Prima hydraulic ironworkers have been designed and built to the highest quality standards in the industry.

This profitable machine will serve any grueling fabrication shop for decades to come. This machine is typically in stock for quick deliveries.